A kind of cellulose/silk fibroin composite airgel long fiber and preparation method thereof

A composite aerogel and silk fibroin technology is applied in the field of cellulose/silk fibroin composite aerogel long fibers and their preparation, which can solve the problem that the silk fibroin solution becomes dry and effective measures are not taken to improve the aerogel. Mechanical properties, difficulty of aerogel fibers, etc., to achieve the effect of simple process, conducive to mass production and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

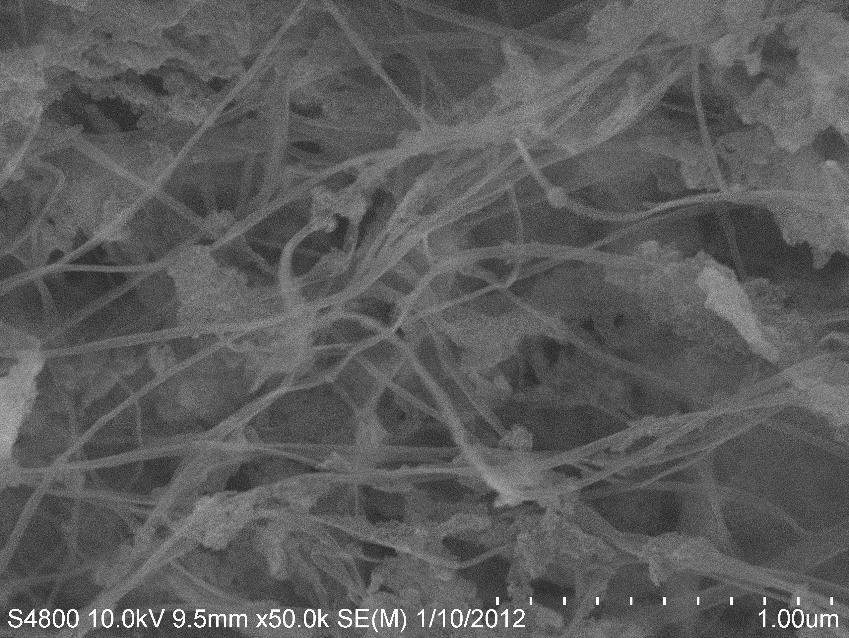

[0021] Step (1), the preparation of the cellulose matrix: a large size of the thickness of 4 mm, length 280 mm, width 220 mm, is cut into a thickness of 4 mm, a width of 7 mm, a length of 9m, and a cropped fermentation The coconut is immersed in a 3% NaOH aqueous solution, and the temperature was heated with a hydropathically heated with an oil bath at a temperature of 82 ° C, and the soaking of a good fermented coconut flakes; the pH meter was monitored, and the pH was washed with deionized water. Sexual use, to obtain a cellulose matrix;

[0022] Step (2), the preparation of the silk fibroin solution: cutting the silkworm cocoon into a small piece of 8 × 8 mm, after immersion in aqueous solution of 0.09 mol / L, heated with an oil bath at 95 ° C temperature 50 ~ 60min. The degummed treatment was carried out, then removed, placed in a petri dish for 17 hours at 48 ° C for 17 hours, and lithium bromide of 10.7 mol / L after drying, the mass ratio of lithium bromide solution was 1:...

Embodiment 2

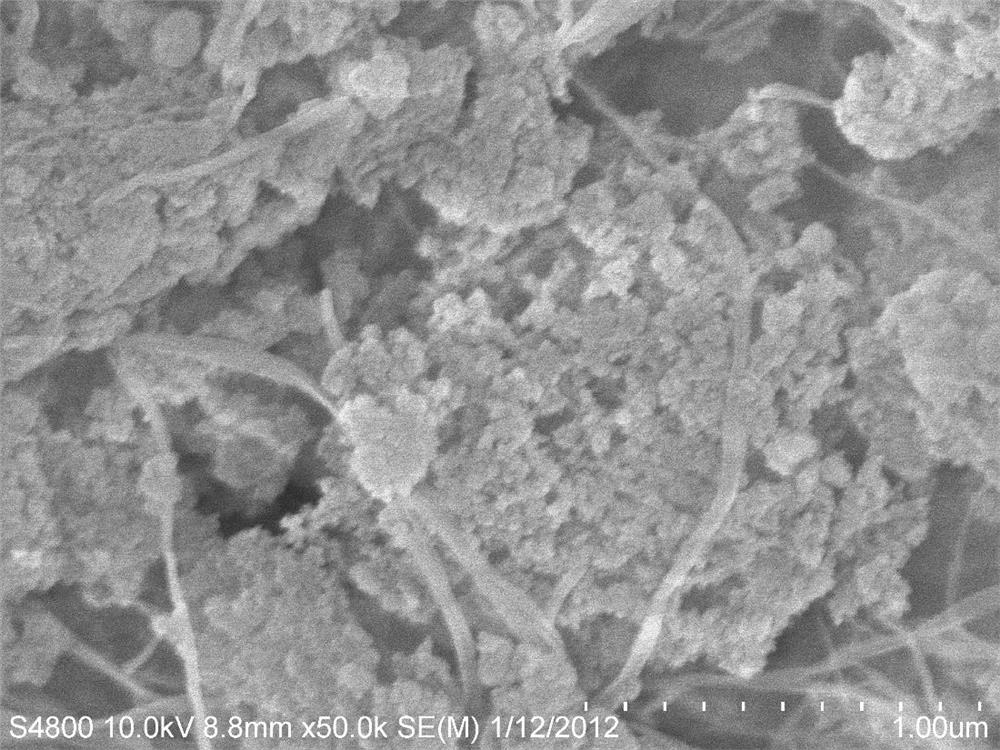

[0029] Step (1), the preparation of the cellulose matrix: cut the thickness of 2 mm to a thickness of 2 mm, a width of 5 mm, a length of 12 m, and immerse cropped fermentation coconut sheets in 4% In the NaOH aqueous solution, the temperature was heated with a hydropathically heated treatment of 120min under temperature conditions at 90 ° C, and the pH is monitored; the pH changes are monitored, and the deionized water is washed to neutral spare to obtain cellulose. Matrix;

[0030] Step (2), the preparation of the silk fibroin solution: cut the silkworm cocoons into small pieces of 10 × 10 mm, after immersion in aqueous solution of 0.02 mol / L, aqueous solution of sodium hydrogencarbonate, heated under temperature at 90 ° C for 70 min under temperature conditions Dehydrate, then removed, put it in a petri dish for 12 hours at 40 ° C for 12 hours, after drying, lithium bromide, lithium bromide, silkworm and bromide solution is 1: 10, with oil bath It was heated under a constant t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com