Water-soluble rare earth nanocrystalline, and application and preparation method thereof

A nanocrystalline, water-soluble technology, applied in nanotechnology, nano optics, nanotechnology, etc., can solve problems such as shedding, interference with ligands, and low yield, and achieve the effects of simple operation, low cost, and improved energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

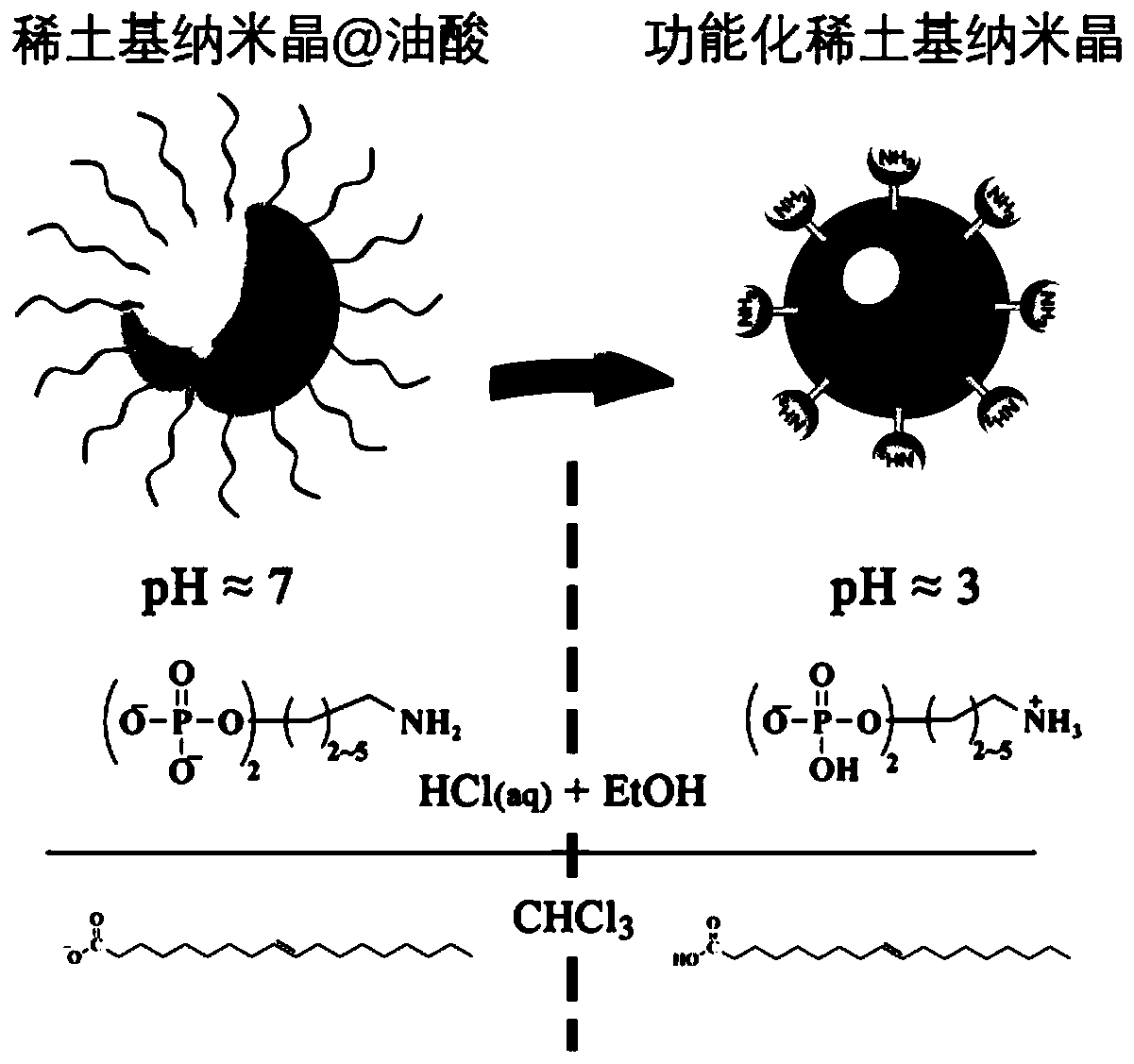

[0039] combined with figure 1 , Synthesize up-conversion rare earth nanocrystalline NaYF by oleic acid method 4 -Oleic acid and qualified small molecule alendronic acid as an example:

[0040] (1) 200mg NaYF 4 -Use 10mL of chloroform to ultrasonically disperse oleic acid in a 50mL centrifuge tube;

[0041] (2) After adding 4 mL of ethanol and 10 mL of water to form a ternary two-phase interface, add 50 mg of alendronic acid to the water phase;

[0042] (3) Add dropwise 1M hydrochloric acid to adjust the pH to between 2-3, add magnets to stir, 880 rpm, 10 minutes;

[0043] (4) Transfer the aqueous phase to another centrifuge tube, add 10mL, 100mM, PH=7.4 HEPES biological buffer solution, then centrifuge at 8000 rpm for 5 minutes to remove the supernatant;

[0044] (5) Add 5 mL of 1 mM hydrochloric acid solution to the centrifuged product for ultrasonic dispersion;

[0045] (6) After repeating steps (4) and (5) three times, the final product was ultrasonically dissolved in...

Embodiment 2

[0055] Synthesis of Upconversion Rare Earth Nanocrystalline NaHoF by Oleylamine Method 4 :Yb, Tm-oleylamine and the small molecule pamidronic acid that meet the requirements are taken as an example:

[0056] (1) 400mg NaHoF 4 :Yb, Tm-oleylamine is ultrasonically dispersed in 50mL centrifuge tube with 10mL chloroform;

[0057] (2) After adding 2 mL of ethanol and 6 mL of water to form a ternary two-phase interface, add 100 mg of pamidronic acid to the water phase;

[0058] (3) Add dropwise 1M hydrochloric acid to adjust the pH to between 2-3, add magnets to stir, 880 rpm, 10 minutes;

[0059] (4) Transfer the aqueous phase to another centrifuge tube, add 10mL, 100mM, PH=7.4 HEPES biological buffer solution, then centrifuge at 8000 rpm for 5 minutes to remove the supernatant;

[0060] (5) Add 5 mL of 1 mM hydrochloric acid solution to the centrifuged product for ultrasonic dispersion;

[0061] (6) After repeating steps (4) and (5) three times, the final product was ultrasoni...

Embodiment 3

[0068] Synthesis of Upconversion Rare Earth Nanocrystalline NaYF by Oleic Acid Method 4 : Yb, Er-oleic acid and small molecule alendronic acid that meet the requirements as an example:

[0069] (Among them, NaYF4:Yb, Er is a substance that uses NaYF4 as a matrix, efficiently absorbs near-infrared light through the sensitizing ion Yb, and transmits it to the adjacent active ion Er, thereby realizing upconversion luminescence.)

[0070] (1) 100mgNaYF 4 :Yb, Er-oleic acid is ultrasonically dispersed in 25mL centrifuge tube with 10mL chloroform;

[0071] (2) After adding 2 mL of ethanol and 5 mL of water to form a ternary two-phase interface, add 50 mg of alendronic acid to the water phase;

[0072] (3) Add dropwise 1M hydrochloric acid to adjust the pH to between 2-3, add magnets to stir, 880 rpm, 10 minutes;

[0073] (4) Transfer the aqueous phase to another centrifuge tube, add 10mL, 100mM, PH=7.4 HEPES biological buffer solution, then centrifuge at 8000 rpm for 5 minutes to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com