Planar capacitor and manufacturing method thereof

A production method and capacitor technology, applied in the field of capacitors, can solve the problems of demanding technical personnel, complicated production process, and low capacitance density, and achieve the effects of reducing the difficulty of production process, diverse and flexible preparation methods, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

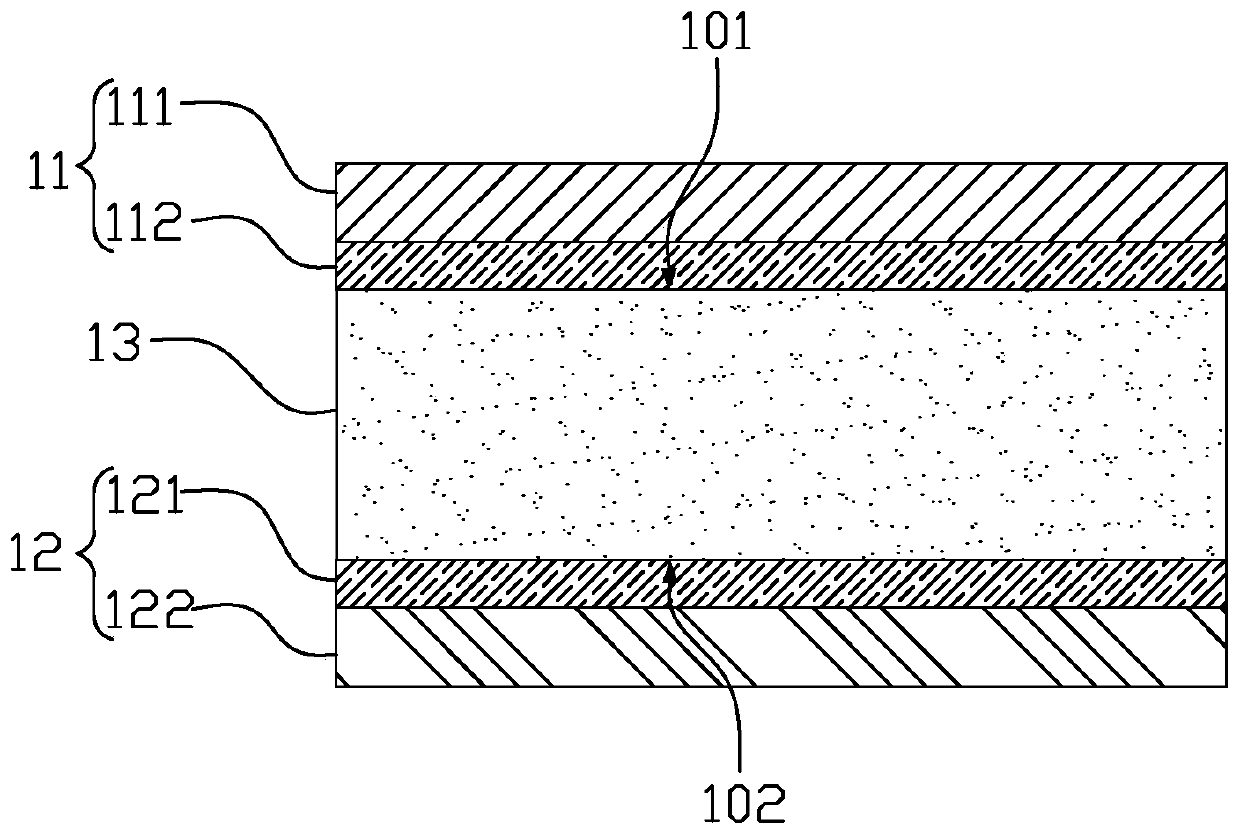

[0028] figure 2 It is a schematic diagram of a partial cross-sectional structure of a planar capacitor of the present invention, such as figure 2 As shown, the planar capacitor includes a first electrode 11, a second electrode 12 and a dielectric layer 13, the dielectric layer 13 is located between the first electrode 11 and the second electrode 12, the dielectric constant of the dielectric layer is greater than 100, and the first electrode 11 includes The first conductive layer 111 and the second conductive layer 112 with viscosity, the first conductive layer 111 is stuck on the second conductive layer 112, the second conductive layer 112 is stuck on the dielectric layer 13, and the second electrode 12 includes the third conductive layer 121 and an adhesive fourth conductive layer 122 , the third conductive layer 121 is adhered to the fourth conductive layer 122 , and the fourth conductive layer 122 is adhered to the dielectric layer 13 . Preferably, the dielectric layer 1...

no. 2 example

[0041] The present invention also relates to a method for manufacturing a planar capacitor, the method comprising:

[0042] Making the first electrode 11, the second electrode 12 and the dielectric layer 13, the dielectric constant of the dielectric layer 13 is greater than 100;

[0043]Wherein, the dielectric layer 13 is located between the first electrode 11 and the second electrode 12, the first electrode 11 includes a first conductive layer 111 and a viscous second conductive layer 112, the first conductive layer 111 sticks to the second conductive layer 112 On, the second conductive layer 112 sticks on the medium layer 13, the second electrode 12 includes the third conductive layer 121 and the fourth conductive layer 122 with viscosity, the third conductive layer 121 sticks on the fourth conductive layer 122, the fourth The conductive layer 122 is glued on the dielectric layer 13 . Preferably, the dielectric layer 13 is made of a mixed dielectric material with a high die...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com