Double-layer polymer-based electric response shape memory material and preparation method thereof

A polymer-based, memory material technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, chemical instruments and methods, synthetic resin layered products, etc., can solve the problem of small variable range of shape memory properties and adjustment of conductive properties Single method, difficult to control the dispersion of conductive particles and other problems, to achieve the effect of easy continuous production, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

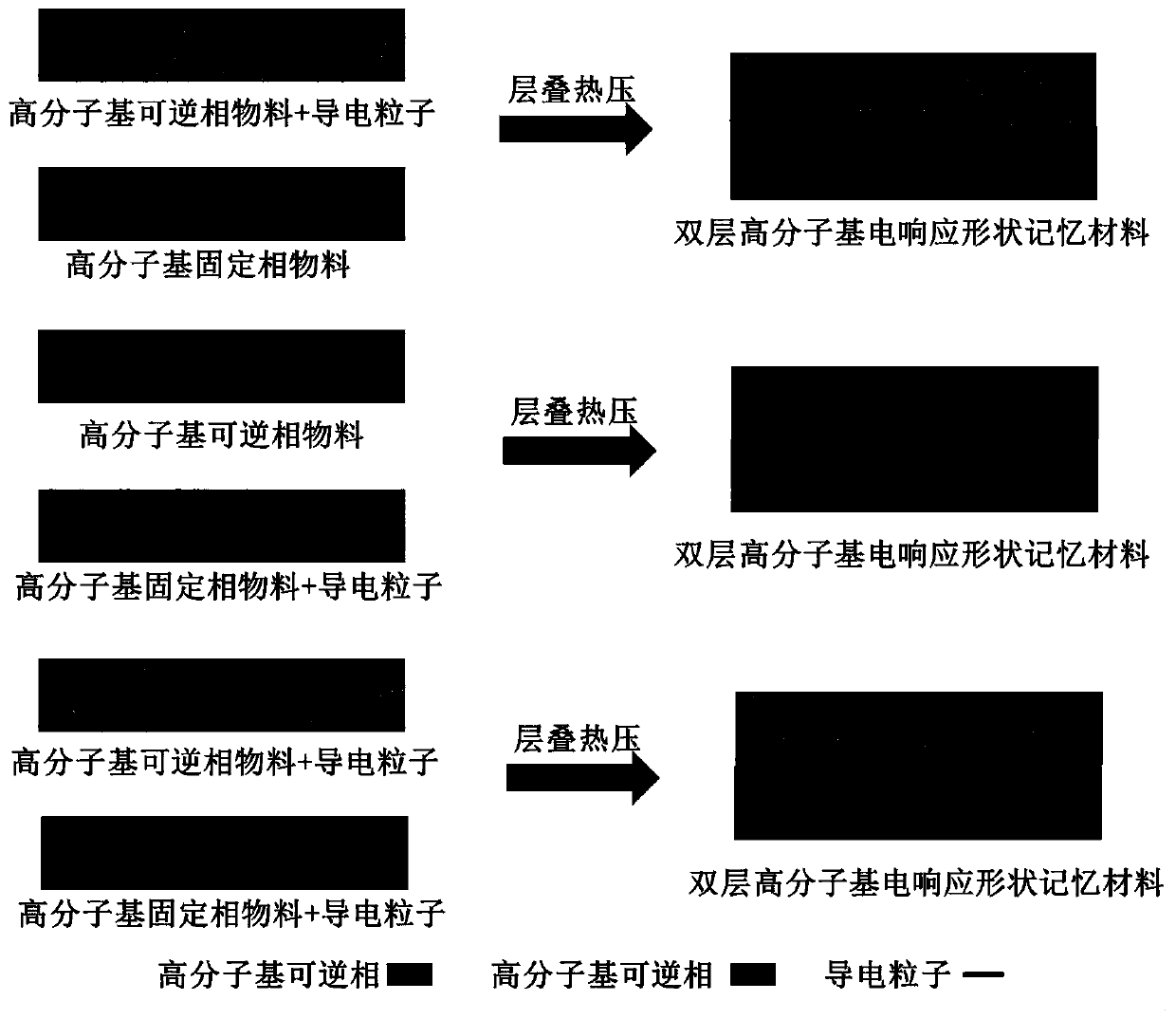

Method used

Image

Examples

Embodiment 1

[0033] (1) Polycaprolactone (PCL) (6800, Perstorp Corp) was selected as the shape memory reversible phase, and thermoplastic polyurethane elastomer (TPU) (S85A11, BASF) with a Shore hardness of 85A was used as the shape memory stationary phase, with an average diameter of Multi-walled carbon nanotubes (MWCNTs) (NC 7000, Nanocyl SA) with a length of 9.5 nm and a length of 1.5 μm were used as conductive particles. Before use, the raw materials were placed in a vacuum oven and dried at 40°C, 80°C, and 80°C for 24 hours to remove moisture.

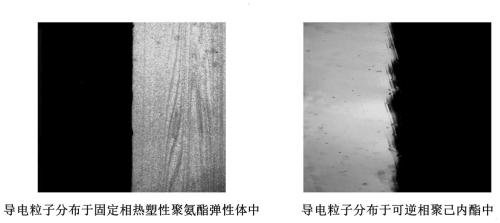

[0034](2) Mix TPU and MWCNTs evenly at a mass ratio of 95:5, and then extrude and granulate through a twin-screw extruder. The temperature of each section of the extruder is 165-180-180-180˚C. The TPU / MWCNTs composite masterbatch and PCL are uniformly hot-pressed into a thin sheet with a thickness of 0.6mm, and then the two sheets are laminated in parallel and hot-pressed again to obtain a two-layer composite with a two-phase layer thickness r...

Embodiment 2

[0036] The stimulation voltage was adjusted up to 30V, and the others were the same as in Example 1. After calculation and testing, the shape recovery rate of this material is equivalent to that of Example 1, but the shape recovery speed is accelerated, and the shape recovery can be completed within 30s.

Embodiment 3

[0038] Mix TPU and MWCNTs at a mass ratio of 97:3, and PCL and MWCNTs at a mass ratio of 98:2, respectively, and then extrude and granulate through a twin-screw extruder, and hot-press the two composite masterbatches into a thickness of 0.6 mm, the others are the same as in Example 1. After calculation and detection, the resistivity in this material is reduced to 12.0Ω·cm, and the shape recovery speed is accelerated, and the shape recovery can be completed within 25 s under the stimulation of 20v voltage, and the shape recovery rate is equivalent to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com