Composite phosphorus removal material based on collophanite and application method thereof

An application method, collophosite technology, applied in the field of phosphorus pollution control, can solve the problems of low phosphorus fixation efficiency, difficulty in applying domestic sewage and farmland water return treatment, etc., and achieve the effect of improving phosphorus removal effect, pore development, and sufficient contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

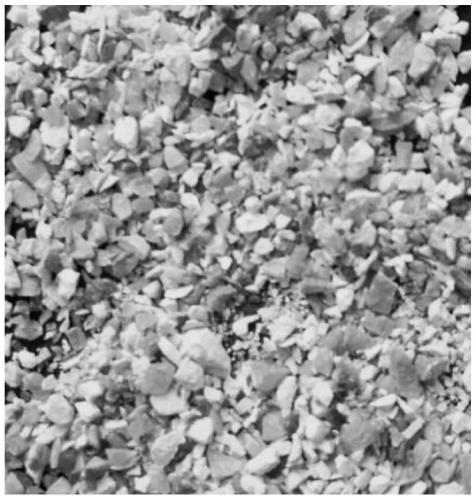

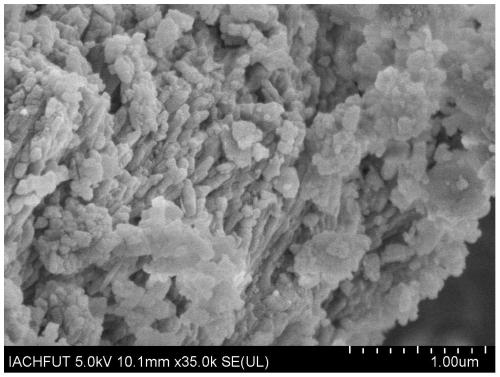

[0029] 50kg of colloidal ore was purchased from a phosphate mine, and its mineral composition was obtained by chemical phase analysis: 70.4% apatite, 15.7% dolomite, and 13.9% quartz. The apatite morphology was as follows figure 1 shown.

[0030] 50kg of anhydrite ore was collected from Hanshan, and its mineral composition was obtained by chemical phase analysis: 96.4% of anhydrite, 2.6% of dolomite, and 1% of quartz.

[0031] 50 kg of calcined magnesite was purchased from Liaoning, and its mineral composition was obtained by chemical phase analysis: 88.4% of periclase and 11.6% of talc.

[0032] The three raw materials were crushed and sieved respectively to obtain particles with a particle size of 0.5-1mm, and then mixed uniformly according to the mass percentage of 40% of collophanite particles, 20% of calcined magnesite particles, and 40% of anhydrite particles, that is A composite phosphorus removal material for filtration is obtained.

[0033] Pack the composite phosph...

Embodiment 2

[0037] In this example, the same raw materials of calcined magnesite and anhydrite as in Example 1 were used, which were crushed and sieved respectively to obtain particles with a particle size of 0.8-2 mm.

[0038] 5kg of low-grade collophosite ore was collected, and its mineral composition was obtained by chemical phase analysis: 37.8% apatite, 39.3% dolomite, and 22.7% quartz. It is crushed and sieved to obtain particles with a particle size of 1-2mm.

[0039] Put the collophanite particles in a muffle furnace for calcination at 800°C for 1 hour, the dolomite in it is completely decomposed into periclase, rinse with water for 5 minutes after cooling, and dry to obtain calcined collophanite ore.

[0040] According to the mass percentages of 60% of calcined collophanite, 10% of calcined magnesite particles and 30% of anhydrite particles, the three raw materials are evenly mixed to obtain a composite phosphorus removal material for filtering.

[0041] Fill the prepared compos...

Embodiment 3

[0043] In this example, the same collianite and anhydrite raw materials as those in Example 1 were used, which were crushed and sieved respectively to obtain particles with a particle size of 0.8-2 mm.

[0044] The dolomite is crushed and sieved to obtain particles with a particle size of 1-2mm, which are calcined in a muffle furnace at 800°C for 1 hour, and then placed in a humid air environment for more than 10 days to obtain calcined dolomite particles.

[0045] According to the mass percentages of 20% collophosite particles, 30% calcined dolomite particles and 50% anhydrite particles, the three raw materials are evenly mixed to obtain a composite phosphorus removal material for filtration.

[0046] Pack the composite phosphorus removal material prepared in this embodiment into a plastic pipe with a diameter of 5 cm and a height of 50 cm to form a water treatment filter column. The simulated phosphorus-containing water with a phosphorus concentration of 4 mg / L prepared with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com