Anaerobic fermentation hydrogen production method using excess sludge as raw material, and additive

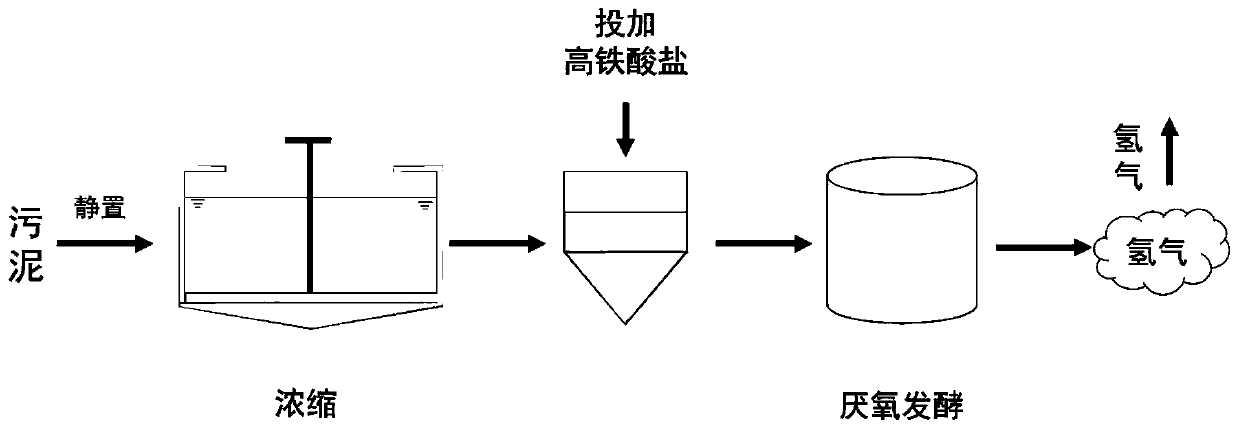

An anaerobic fermentation and residual sludge technology, applied in fermentation, sludge treatment, biological sludge treatment, etc., can solve problems such as increased energy consumption and complex process flow, and achieve simple overall process, reduce environmental pollution, and alleviate energy consumption. effect of shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

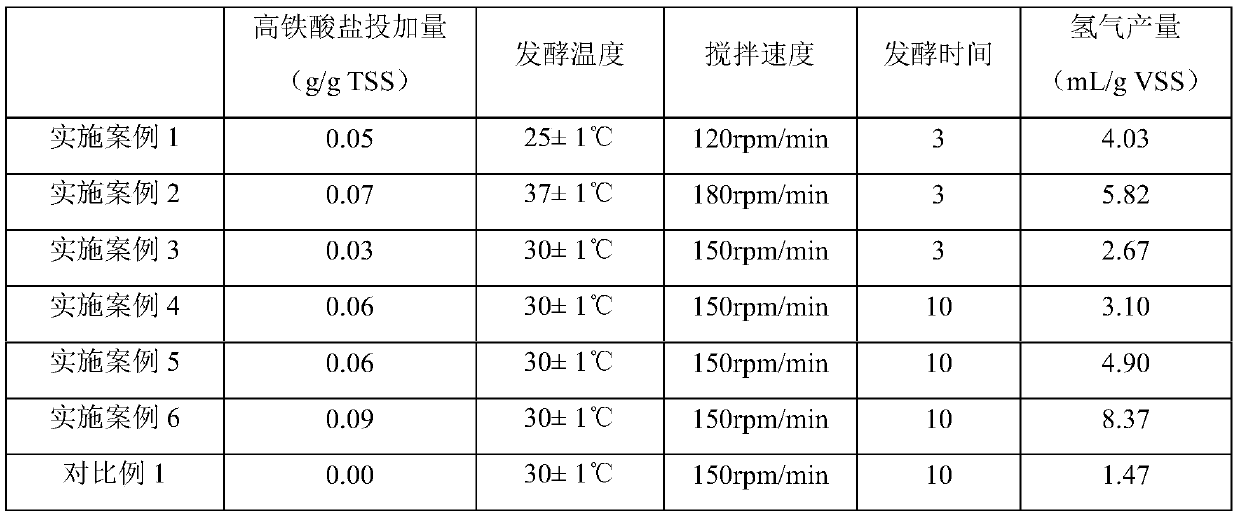

Embodiment 1

[0031] (1) In a plexiglass reactor with a working volume of 1 L, the excess sludge produced by the municipal sewage treatment plant was placed at 3°C for natural settlement for 24 hours, and the fermented raw material (i.e., the excess sludge sample) was obtained after the supernatant was drained. , the following examples are the same).

[0032] (2) Add ferrate of 0.05g / g TSS to the reactor, fill the reactor with nitrogen for 10 minutes to exclude oxygen, seal the reactor and put it in a shaker for anaerobic fermentation. Through the combined action of microorganisms in the sludge and ferrate, the organic matter in the sludge is converted into hydrogen. Among them, the fermentation temperature of the reactor is controlled at 25±1°C, the stirring speed of the shaker is 120rpm / min, the residence time of the sludge in the reactor is 3d, and the output of hydrogen produced is 4.03mL / g VSS.

Embodiment 2

[0034] (1) In a plexiglass reactor with a working volume of 1 L, the excess sludge produced by the urban sewage treatment plant was placed at 5°C for 48 hours to naturally settle, and the fermented raw material (i.e., the excess sludge sample) was obtained after the supernatant was drained. , the following examples are the same).

[0035] (2) Add ferrate of 0.07g / g TSS to the reactor, fill the reactor with nitrogen for 10 minutes to exclude oxygen, seal the reactor and put it in a shaker for anaerobic fermentation. Through the combined action of microorganisms in the sludge and ferrate, the organic matter in the sludge is converted into hydrogen. Among them, the fermentation temperature of the reactor is controlled at 37±1°C, the stirring speed of the shaker is 180rpm / min, the residence time of the sludge in the reactor is 3d, and the output of hydrogen produced is 5.82mL / g VSS.

Embodiment 3

[0037] (1) In a plexiglass reactor with a working volume of 1 L, the excess sludge produced by the urban sewage treatment plant was placed at 4°C for natural settlement for 24 hours, and the fermented raw material (i.e., the excess sludge sample) was obtained after the supernatant was drained. , the following examples are the same).

[0038] (2) Add ferrate of 0.03g / g TSS to the reactor, fill the reactor with nitrogen for 10 minutes to exclude oxygen, seal the reactor and put it in a shaker for anaerobic fermentation. Through the combined action of microorganisms in the sludge and ferrate, the organic matter in the sludge is converted into hydrogen. Among them, the fermentation temperature of the reactor is controlled at 30±1°C, the stirring speed of the shaker is 150rpm / min, the residence time of the sludge in the reactor is 3d, and the output of hydrogen produced is 2.67mL / g VSS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com