Sweetening agent composition for dry packaging paper

A technology of food wrapping paper and sweetener, which is applied in the direction of wrapping paper, wrapping paper, and food ingredients as taste improvers, etc. It can solve the problems of not full layers, single sweetness, and need to improve clarity, so as to increase sales, The effect of increasing the sense of body fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Sweetener composition deployment: the selection of ethyl acetate, 3% neotame, 1% sucralose, 2% perilla, 3% citric acid, 11% water, 10 % sodium saccharin, 10% acesulfame potassium, and 5% glycerol triacetate were sequentially added to the container according to a certain weight ratio, and stirred for 60 min by a disperser under the stirring condition of 600 r / min to make the mixture completely Dissolve and stir well. Further, using the base paper provided by a certain domestic tipping paper as an object, the prepared sweetener composition was used to continue to prepare sweet varnish, and after printing, bronzing, slitting and other processes, it was made into a sweet-tasting heating cigarette. Tipping paper.

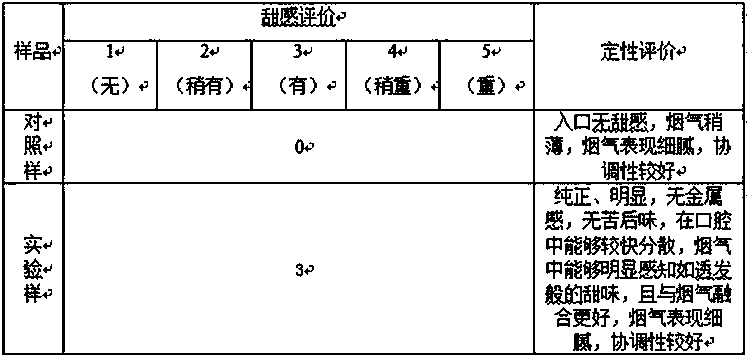

[0020] In order to verify the sweetness of the wrapping paper, keeping other conditions unchanged, the tipping paper produced without using the sweetener composition was used as a control sample, and rolled together to make heated cigarettes. The two samples wer...

Embodiment 2

[0023] Sweetener composition deployment: selection of 50% ethyl acetate, 5% neotame, 1% sucralose, 2% ethyl maltol, 3% citric acid, 14% water , 5% sodium saccharin, 15% acesulfame potassium, and 5% glycerol triacetate were sequentially added to the container according to a certain weight ratio, and stirred for 60 min by a disperser under the stirring condition of 600 r / min to make The mixture is completely dissolved and stirred well. Further, using the base paper provided by a certain domestic tipping paper as an object, the prepared sweetener composition is used to continue to prepare sweet varnish, and after printing, bronzing, cutting and other processes, it is made into a conventional cigarette with a sweet taste. Tipping paper.

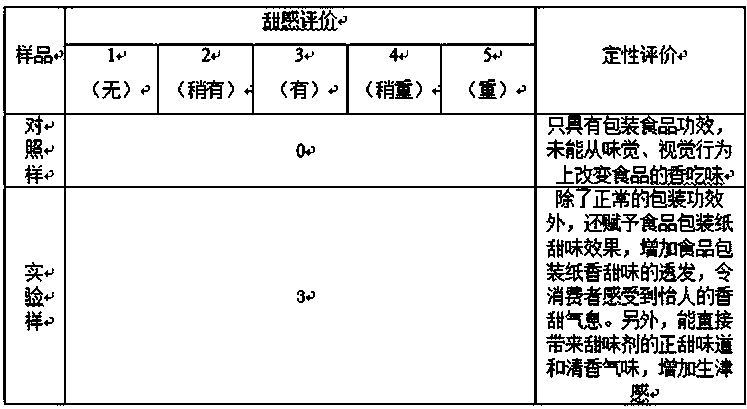

[0024] In order to verify the sweetness of the wrapping paper, keeping other conditions unchanged, the tipping paper produced without using the sweetener composition was used as a control sample, and rolled into conventional cigarettes together....

Embodiment 3

[0027] Sweetener composition deployment: selection of 53% ethyl acetate, 2% neotame, 2% sucralose, 3% perilla scape, 3% citric acid, 13% water, 12% sodium saccharin, 7% acesulfame potassium, and 5% glycerol triacetate were sequentially added to the container according to a certain weight ratio, and stirred for 60 min by a disperser under the stirring condition of 600 r / min to make the mixture Dissolve completely and stir well. Furthermore, using the base paper provided by a certain domestic tipping paper as an object, the prepared sweetener composition was used to continue to prepare sweet varnish, and after printing, bronzing, slitting and other processes, a candy packaging with sweet taste was made Paper.

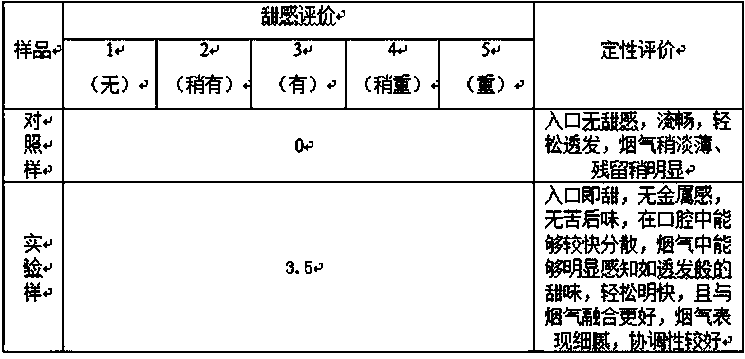

[0028] In order to verify the sweetness of the wrapping paper, keeping other conditions unchanged, the wrapping paper produced without using the sweetener composition was used as a control sample, and rolled together to make a practical candy. The two samples were store...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com