All-solid-state polymer electrolyte based on zwitterionic liquid modified polyvinyl alcohol and preparation method of all-solid-state polymer electrolyte

An all-solid polymer, zwitterion technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of low glass transition temperature, easy leakage, etc., achieve good conductivity, and overcome the effect of difficult molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

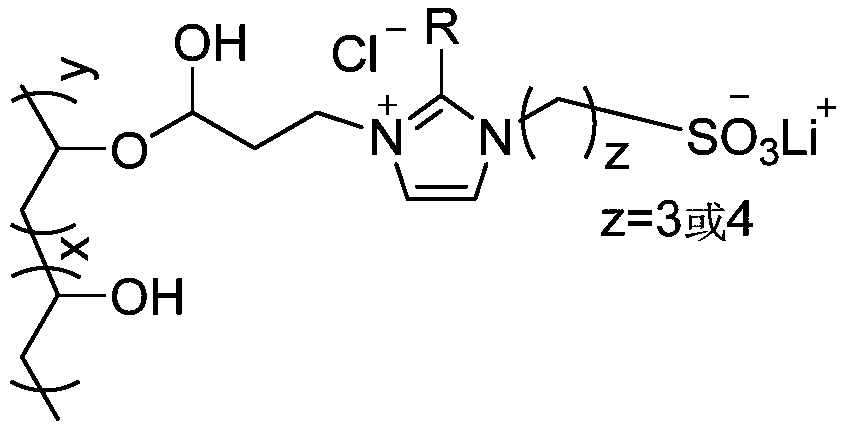

[0025] This embodiment provides an all-solid polymer electrolyte based on amphoteric ionic liquid modified polyvinyl alcohol and its preparation method, the specific steps are as follows:

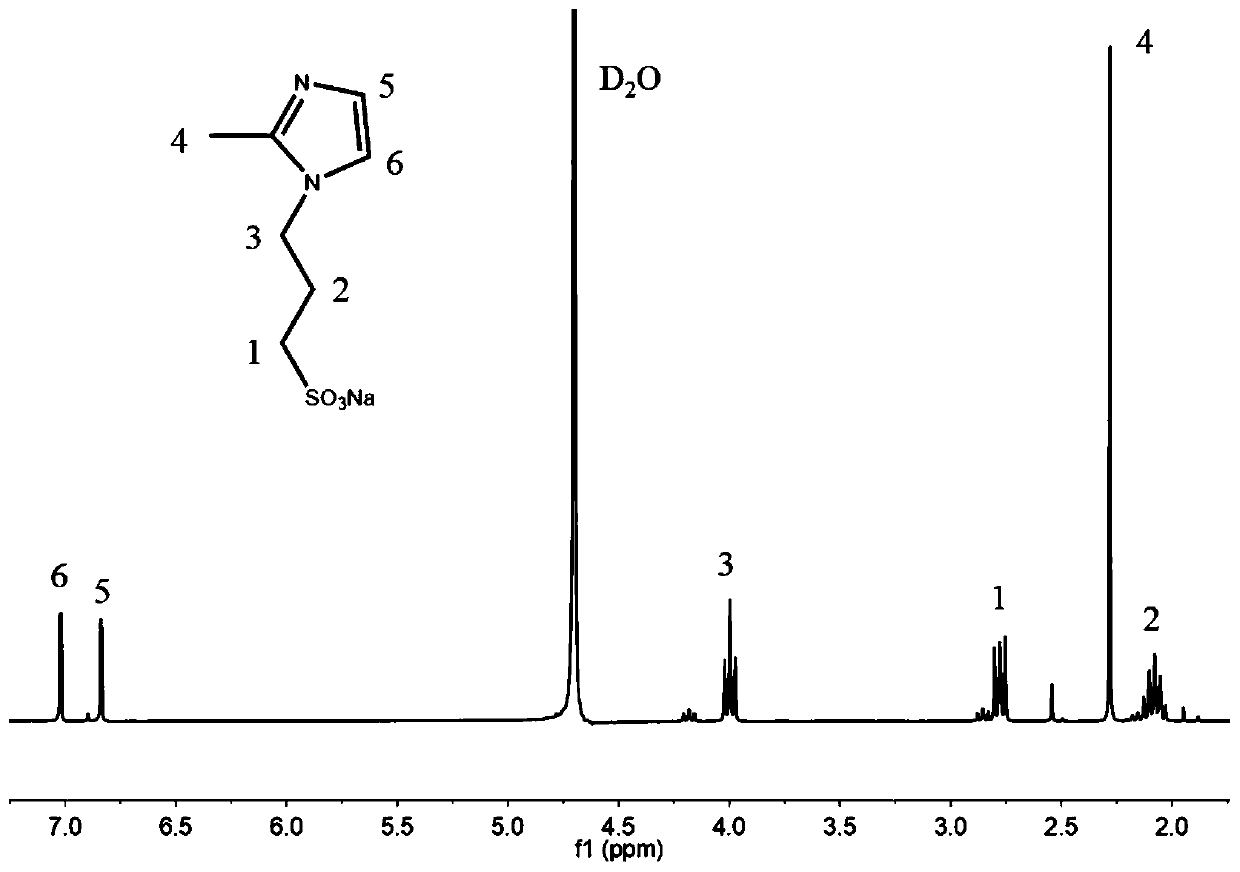

[0026] (1) Dissolve 4.11g 2-methylimidazole (0.05mol) and 6.11g 1,3-propane sultone (0.05mol) in 60ml acetonitrile, add 1.44g sodium hydride (0.06mol) under nitrogen atmosphere Wherein, react at 40°C for 24 hours to obtain a white precipitate, wash the obtained precipitate with acetonitrile three times, and dry at 60°C to obtain the product imidazolium salt: 3-(2-methylimidazole)-propanesulfonate sodium.

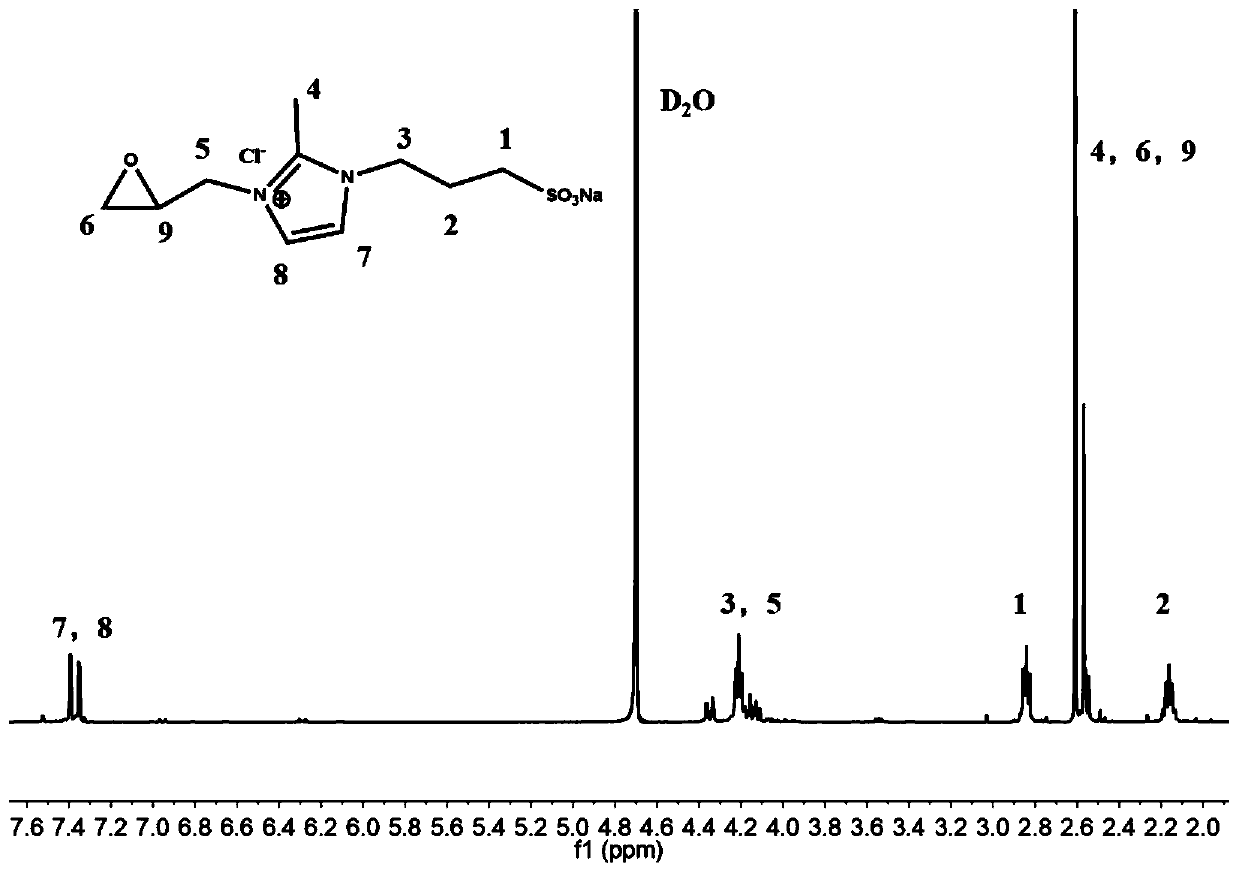

[0027] (2) Add 4.04g of 3-(2-methylimidazole)-propanesulfonate sodium (0.02mol) and 1.85g of epichlorohydrin (0.02mol) to 50ml of dimethyl sulfoxide, under nitrogen atmosphere at 60°C React for 48 hours. Pour the mixed solution into ethyl acetate to precipitate an oily substance, and continue to wash with ethyl acetate for 3 times to obtain a zwitterionic liquid.

[0028] (3) Dissolve 1...

Embodiment 2

[0033] This embodiment provides an all-solid polymer electrolyte based on zwitterionic liquid modified polyvinyl alcohol and its preparation method, which is basically the same as that in Example 1: the difference is that in step (3), the zwitterionic liquid The mass is 3.00g, and the conductivity of the obtained all-solid polymer electrolyte assembled battery at room temperature is 3.16×10 -5 S / cm -1 . In order to test the application of solid-state electrolytes in all-solid-state batteries, it was assembled into LiFePO 4 / SPE / Li batteries were tested for charge-discharge cycles at 60°C. The first discharge specific capacity of the battery measured at 0.1C rate is 188mAh·g -1 .

Embodiment 3

[0035] This example This example provides an all-solid polymer electrolyte based on zwitterionic liquid modified polyvinyl alcohol and its preparation method, which is basically the same as that in Example 1: the difference is that in step (3), the amphoteric The mass of the ionic liquid is 0.50 g. The conductivity of the obtained all-solid polymer electrolyte assembled battery at room temperature was 1.43×10 -6 S / cm -1 . In order to test the application of solid-state electrolytes in all-solid-state batteries, it was assembled into LiFePO 4 / SPE / Li batteries were tested for charge-discharge cycles at 60°C. The first discharge specific capacity of the battery measured at 0.1C rate is 150mAh·g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com