Nanocone structure polypyrrole/metal mesh porous filter membrane and preparation method and application thereof

A technology of polypyrrole and nanocones, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of limited bonding strength between separation membrane and substrate, complex preparation process, and low recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

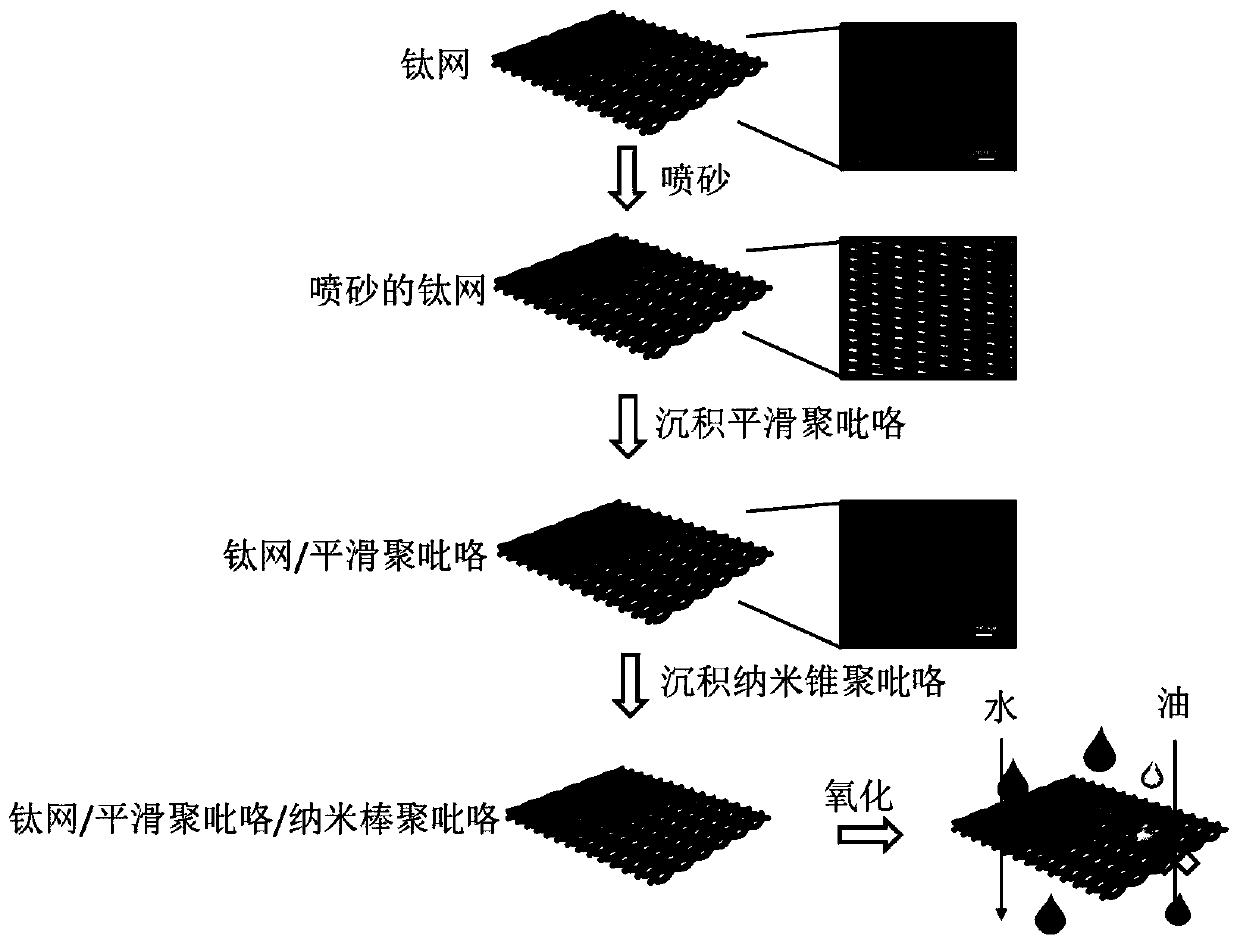

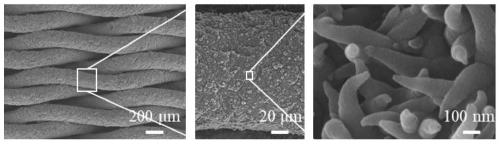

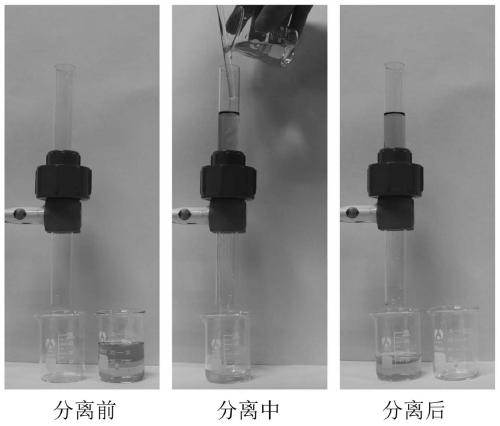

[0039] First, a 3cm×3cm titanium mesh (320 mesh) was super-cleaned with deionized water, 99.7% absolute ethanol and 99.5% acetone for 20 minutes each, and then washed with hydrofluoric acid / nitric acid mixed solution (water:hydrofluoric acid) : The nitric acid volume ratio is 1:1:100) Ultrasonic pickling titanium mesh for 30 minutes, cleaning and drying the pickled titanium mesh, and then sandblasting the titanium mesh with a sandblasting machine, the sandblasting air pressure is 0.4MPa, treatment The time is 2 minutes.

[0040] Then, select the three-electrode mode, the conductive substrate (sandblasted titanium mesh) is the working electrode, the copper sheet is the counter electrode, the silver / silver chloride electrode is the reference electrode, and the concentration of pyrrole in the electrolyte solution is 0.2mol / L , the concentration of hydrochloric acid is 0.25mol / L. The electrochemical reaction was controlled by a constant voltage method, and the reaction potential ...

Embodiment 2

[0048] First, a 3cm×3cm titanium mesh (320 mesh) was super-cleaned with deionized water, 99.7% absolute ethanol and 99.5% acetone for 20 minutes each, and then washed with hydrofluoric acid / nitric acid mixed solution (water:hydrofluoric acid) : The nitric acid volume ratio is 1:1:100) Ultrasonic pickling titanium mesh for 30 minutes, cleaning and drying the pickled titanium mesh, and then sandblasting the titanium mesh with a sandblasting machine, the sandblasting air pressure is 0.4MPa, treatment The time is 2 minutes.

[0049] Then, select the three-electrode mode, the conductive substrate (sandblasted titanium mesh) is the working electrode, the copper sheet is the counter electrode, the silver / silver chloride electrode is the reference electrode, and the concentration of pyrrole in the electrolyte solution is 0.2mol / L , the concentration of hydrochloric acid is 0.25mol / L. The electrochemical reaction was controlled by a constant voltage method, and the reaction potential ...

Embodiment 3

[0056] First, a 3cm×3cm titanium mesh (320 mesh) was super-cleaned with deionized water, 99.7% absolute ethanol and 99.5% acetone for 20 minutes each, and then washed with hydrofluoric acid / nitric acid mixed solution (water:hydrofluoric acid) : The nitric acid volume ratio is 1:1:100) Ultrasonic pickling titanium mesh for 30 minutes, cleaning and drying the pickled titanium mesh, and then sandblasting the titanium mesh with a sandblasting machine, the sandblasting air pressure is 0.4MPa, treatment The time is 2 minutes. The sand selection for sandblasting is shown in Table 3 below.

[0057] Then, the three-electrode mode was selected, the conductive substrate (sandblasted titanium mesh) was used as the working electrode, the copper sheet was used as the counter electrode, the silver / silver chloride electrode was used as the reference electrode, and pyrrole was dissolved in the electrolyte solution. A constant voltage method was used to control the electrochemical reaction. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com