Method for preparing aromatic hydrocarbon

A technology for aromatic hydrocarbons and hydrocarbons, which is used in the field of catalysts for preparing aromatic hydrocarbons with methanol or co-feeding of the two, and in the field of hydrocarbon compounds, which can solve the problems of easy aggregation or loss of metal components, rapid decrease in aromatic hydrocarbon selectivity, and low BTX selectivity. , to achieve the effect of inhibiting rapid coking and carbon deposition, effective circulating logistics, and high aromatization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Preparation: The HZSM-5 molecular sieve with a silicon-aluminum ratio of 46 was prepared by a hydrothermal method. 2) Loading: The roasted product obtained in step 1) was immersed in a zinc nitrate solution with a concentration of 1 wt% and a chromium nitrate solution with a concentration of 5 wt%, immersed for 10 h, centrifuged, dried overnight at 110 °C, and finally roasted at 550 °C for 5 h; The obtained zinc and chromium modified zeolite is designated as catalyst A.

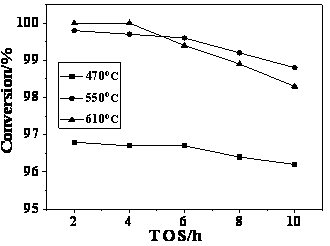

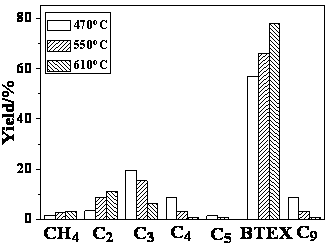

[0027] performance evaluation 1

Embodiment 2

[0037] This example serves to illustrate the catalyst of the present invention.

[0038] 1) Preparation: The HZSM-5 molecular sieve with a silicon-aluminum ratio of 46 was prepared by a hydrothermal method. 2) Loading: The roasted product obtained in step 1) was immersed in a zinc nitrate solution with a concentration of 1 wt% and a chromium nitrate solution with a concentration of 5 wt%, immersed for 10 h, centrifuged, dried overnight at 110 °C, and finally roasted at 550 °C for 5 h; The obtained zinc and chromium modified zeolite is designated as catalyst A.

[0039] 3) Secondary loading: The roasted product obtained in step 2) was immersed in ammonium dihydrogen phosphate solution with a concentration of 3 wt%, immersed for 10 h, centrifuged, dried at 110 °C overnight, and finally roasted at 550 °C for 5 h; zinc, chromium , P modified zeolite, denoted as catalyst B.

[0040] performance evaluation

Embodiment 3

[0043] This example serves to illustrate the catalyst of the present invention.

[0044] 1) Preparation: The HZSM-5 molecular sieve with a silicon-aluminum ratio of 46 was prepared by a hydrothermal method. 2) Loading: The roasted product obtained in step 1) was immersed in a solution of 1 wt% zinc nitrate and 5 wt% chromium nitrate solution, immersed for 10 h, centrifuged, dried overnight at 110 °C, and finally roasted at 550 °C for 5 h; The obtained zinc and chromium modified zeolite is designated as catalyst A. 3) Secondary load

[0045] Immerse the calcined product obtained in step 2) in ammonium dihydrogen phosphate solution with a concentration of 3 wt%, immerse for 10 h, centrifuge, dry overnight at 110°C, and finally roast at 550°C for 5 h; obtain zinc, chromium, and P modified zeolite, Denoted as Catalyst B.

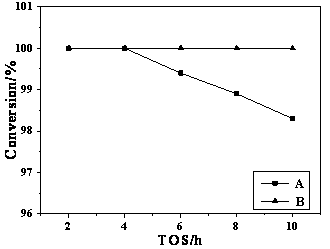

[0046] Performance evaluation: using Example 3 as an example to evaluate the performance of catalyst B.

[0047] 1) 1.0 g of Catalyst B was loaded into a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com