Plant fermentation extract for improving corn planting and preparation method thereof

A plant fermentation and extraction technology, which is applied in the preparation of organic fertilizers, microbial treatment, fertilizer mixtures, etc., can solve the problems of weak lodging resistance of corn plants, low nutrient use efficiency, and poor grain quality, and increase the number of effective microorganisms and activity, beneficial to growth, and the effect of improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

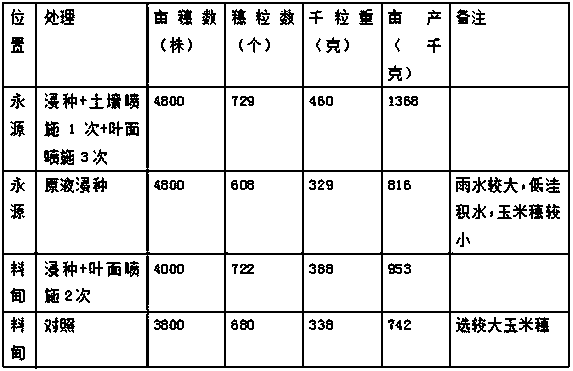

Image

Examples

Embodiment 1

[0042] Embodiment 1: A plant fermented extract for improving corn planting, made by mixing raw materials with the following weight ratio:

[0043] Matsutake 3kg, red ginseng 1kg, flavescens 10kg, salvia miltiorrhiza 10kg, corn silk 5kg, seaweed 10kg, tangerine peel 3kg, eucommia 2kg, cordyceps 1kg, Bupleurum 15kg, zinc-rich yeast 0.03kg, royal jelly 1kg.

[0044] The preparation method is as follows:

[0045] (1) Select the best raw materials;

[0046] (2) Mix and pulverize each raw material, pass through a 30-mesh sieve, and place in a fermenter, wherein the zinc-enriched yeast is dissolved in deionized water and then added with water;

[0047] (3) Add deionized water to the fermentation tank and stir. The amount of deionized water added is 2.5 times the total weight of raw materials. Ferment and age at 37°C for 22 days. odor;

[0048] (4) Add deionized water to the fermenter and stir to adjust the viscosity of the fermentation material to 1.5Pa·S, then cool down to 12°C and...

Embodiment 2

[0053] Embodiment 2: A plant fermented extract for improving corn planting, made by mixing raw materials with the following weight ratio:

[0054] Matsutake 4kg, red ginseng 2kg, flavescens 15kg, salvia miltiorrhiza 15kg, corn silk 10kg, seaweed 15kg, tangerine peel 5kg, eucommia 5kg, cordyceps 2kg, Bupleurum 17kg, zinc-rich yeast 0.05kg, royal jelly 2kg.

[0055] The preparation method is as follows:

[0056] (1) Select the best raw materials;

[0057] (2) Mix and pulverize each raw material, pass through a 35-mesh sieve, and place in a fermenter, wherein the zinc-enriched yeast is dissolved in deionized water and then added with water;

[0058] (3) Add deionized water into the fermentation tank and stir. The amount of deionized water added is 2.8 times the total weight of raw materials. Ferment and age at 43°C for 20 days. odor;

[0059] (4) Add deionized water to the fermenter and stir to adjust the viscosity of the fermentation material to 2.0 Pa·S, then cool down to 18...

Embodiment 3

[0065] Embodiment 3: A plant fermented extract for improving corn planting, made by mixing raw materials with the following weight ratio:

[0066] Matsutake 3.5kg, red ginseng 1.5kg, flavescens 12kg, salvia miltiorrhiza 12kg, corn silk 8kg, seaweed 12kg, tangerine peel 4kg, Eucommia 4kg, cordyceps 1.5kg, Bupleurum 16kg, zinc-rich yeast 0.04kg, royal jelly 1.5kg.

[0067] The preparation method is as follows:

[0068] (1) Select the best raw materials;

[0069] (2) Mix and pulverize each raw material, pass through a 32-mesh sieve, and place in a fermenter, wherein the zinc-enriched yeast is dissolved in deionized water and then added with water;

[0070] (3) Add deionized water to the fermentation tank and stir. The amount of deionized water added is 2.6 times the total weight of raw materials. Ferment and age at 40°C for 21 days. odor;

[0071] (4) Add deionized water to the fermenter and stir to adjust the viscosity of the fermentation material to 1.8Pa·S, then cool down t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com