Mulberry leaf dark tea fermentation process and pre-wetting rotary drum

A fermentation process and drum technology, which is applied in the field of mulberry leaf black tea fermentation process and pre-wet drum, can solve problems such as unsuitable for annual production, long production cycle, and the growth of miscellaneous bacteria, so as to improve the utilization rate of equipment and reduce the cost of enterprises Production cost and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

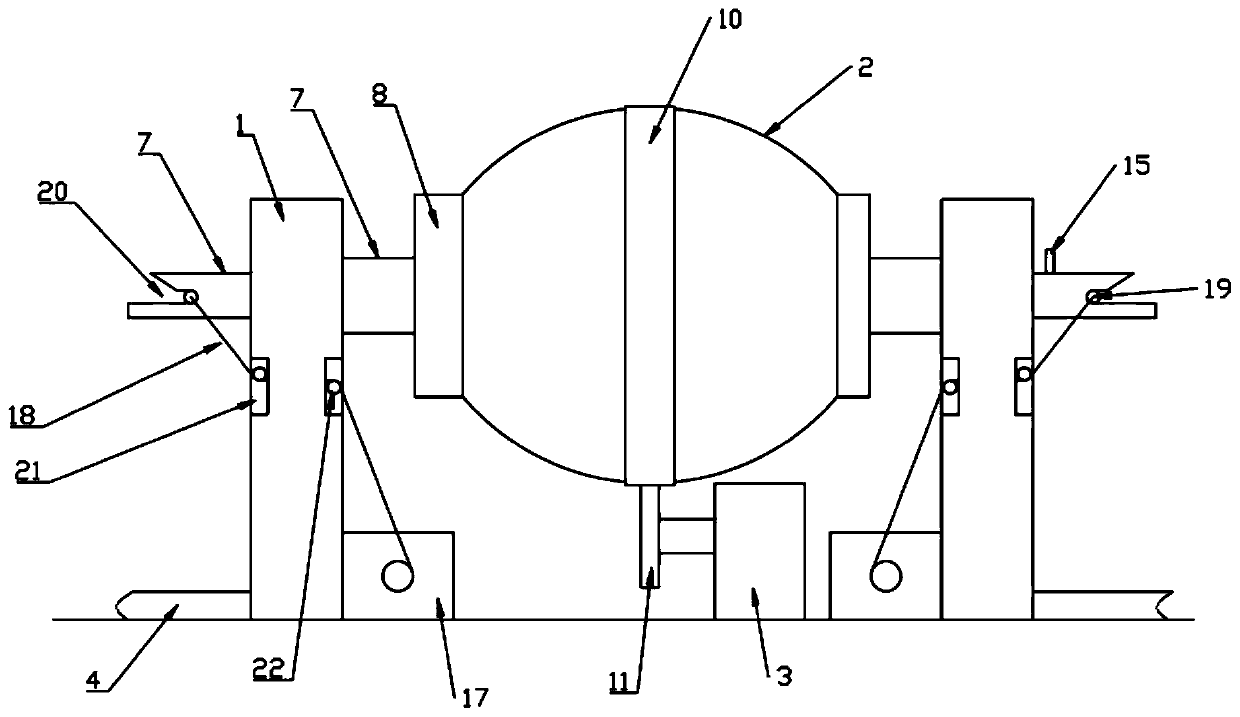

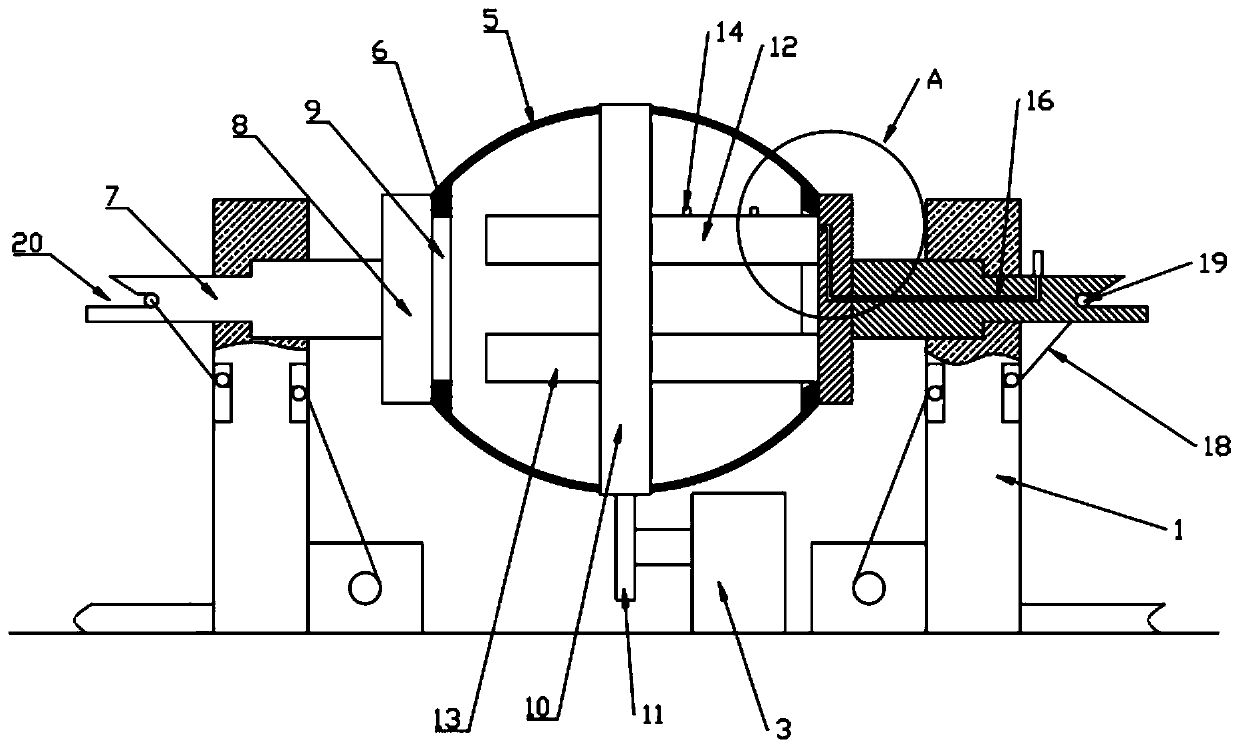

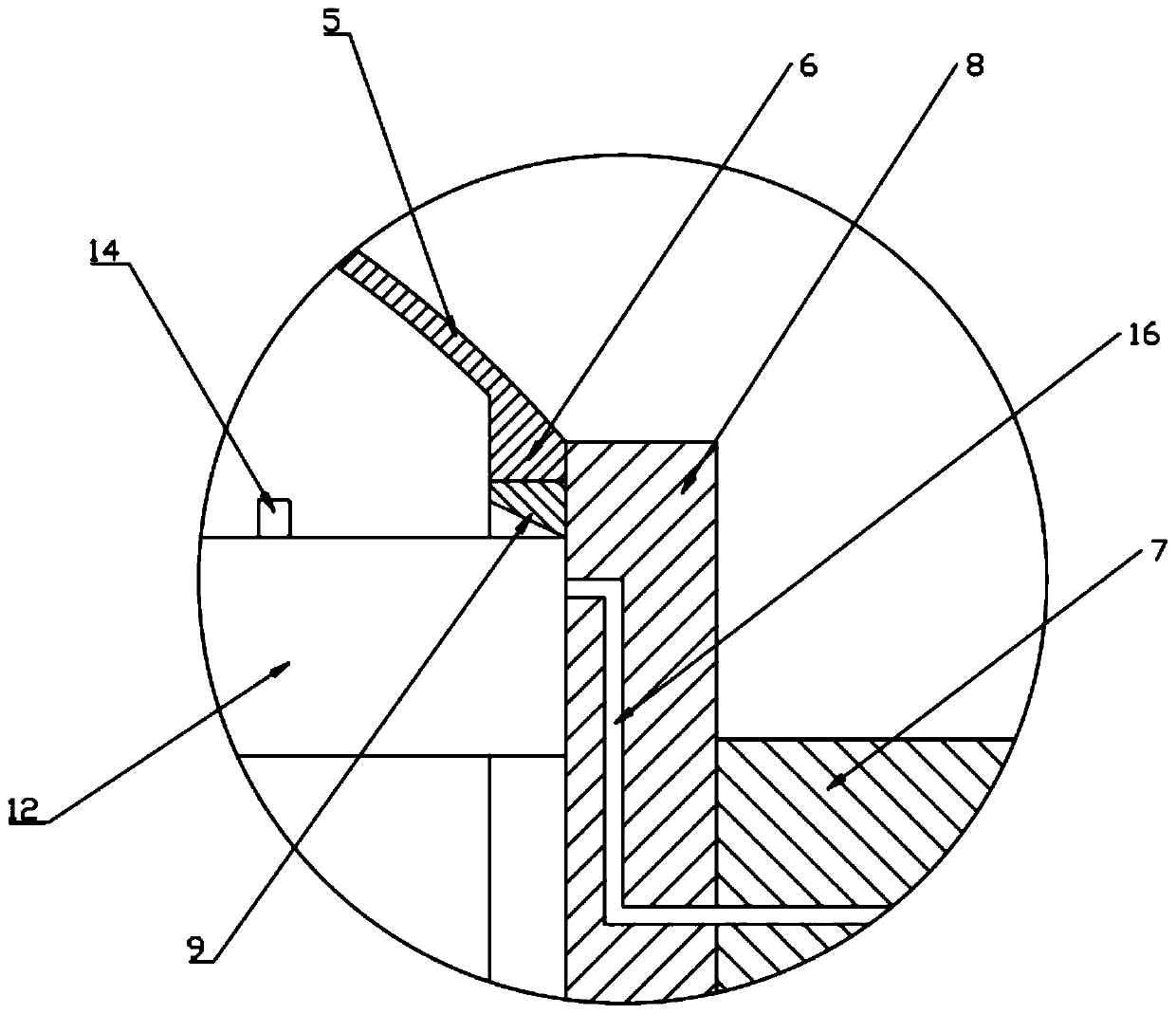

Method used

Image

Examples

Embodiment 1

[0038] Present embodiment provides a kind of mulberry leaf black tea fermentation process, it comprises the following steps:

[0039] The first step: raw material tea production: mulberry leaf raw material tea is harvested mulberry leaves by classification, cleaned, cut leaves, greening, kneaded, dried (dried to 10% moisture content) to become raw material tea;

[0040] Step 2: Use a pre-wet drum to humidify the raw tea until the water is 28%, then transfer it to a 1m*1m*1m or 1m*1m*1.2m fermenter without a cover, and compact the raw tea so that the upper surface Descend to 85% of the original height, and transfer to the fermentation room for the first fermentation, in which 24 fermentation boxes are placed in each fermentation room, arranged in double layers, and can ferment 2.5 tons of mulberry leaf tea each time:

[0041] During the first fermentation process, the temperature of the fermentation chamber is controlled at 40-60°C and the humidity is 60-65%. The heating proces...

Embodiment 2

[0050] The present embodiment provides a kind of mulberry leaf dark tea fermentation process, except for the following content, all the other are the same as embodiment 1, the specific difference is:

[0051] In the first step, the raw tea moisture is dried to 12%;

[0052] In the second step, the raw tea is pre-wetted to a moisture content of 30%;

[0053] During the first fermentation, the heating process in the fermenter is:

[0054] It takes 20 hours to raise the temperature from the initial temperature to 40°C → 24 hours to rise to 50°C → 30 hours to rise to 60°C → 24 hours to rise to 65°C → 24 hours to rise to 68°C → maintain 65°C to 68°C for 24 hours, the whole process is 6 days;

[0055] In the third step, during the second fermentation, the heating process in the fermentation tank is:

[0056] It takes 30 hours for the tea in the box to rise to 40°C → 36 hours for the temperature to 60°C → 30 hours for the temperature to 65°C → 24 hours for the temperature to 68°C → m...

Embodiment 3

[0061] The present embodiment provides a kind of mulberry leaf dark tea fermentation process, except for the following content, all the other are the same as embodiment 1, the specific difference is:

[0062] In the first step, the raw tea moisture is dried to 15%;

[0063] In the second step, the raw tea is pre-wetted to a moisture content of 32%;

[0064] In the fourth step, the raw tea after three times of fermentation is dried to a moisture content of 13%.

[0065] In the above-mentioned Examples 1-3, due to the biological heat generated during the fermentation process and the evaporation of water vapor, etc., the ambient temperature and humidity will change, so the temperature and humidity of the fermentation room are in a state of real-time change. When the temperature of the fermentation room is high At 58°C, turn on the exhaust fan configured in the fermentation room to exhaust and cool down, so that the temperature is within the range required by this process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com