Zinc-doped graphene catalyst as well as preparation method and application thereof

A graphene and zinc doped technology, applied in the field of electrocatalysis, can solve the problems of low atomic utilization rate, high atomic utilization rate, destruction of catalytic sites, etc., and achieve excellent electrocatalytic nitrogen reduction performance, easy availability of raw materials, Outstanding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

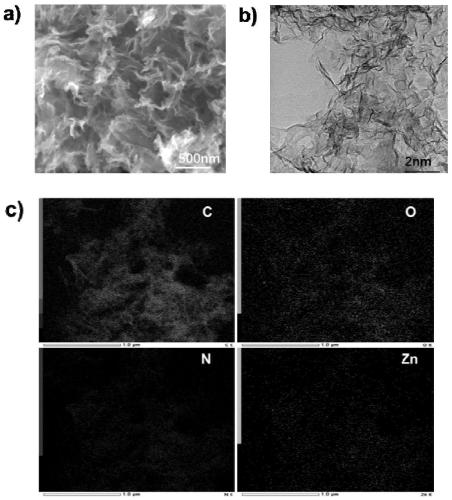

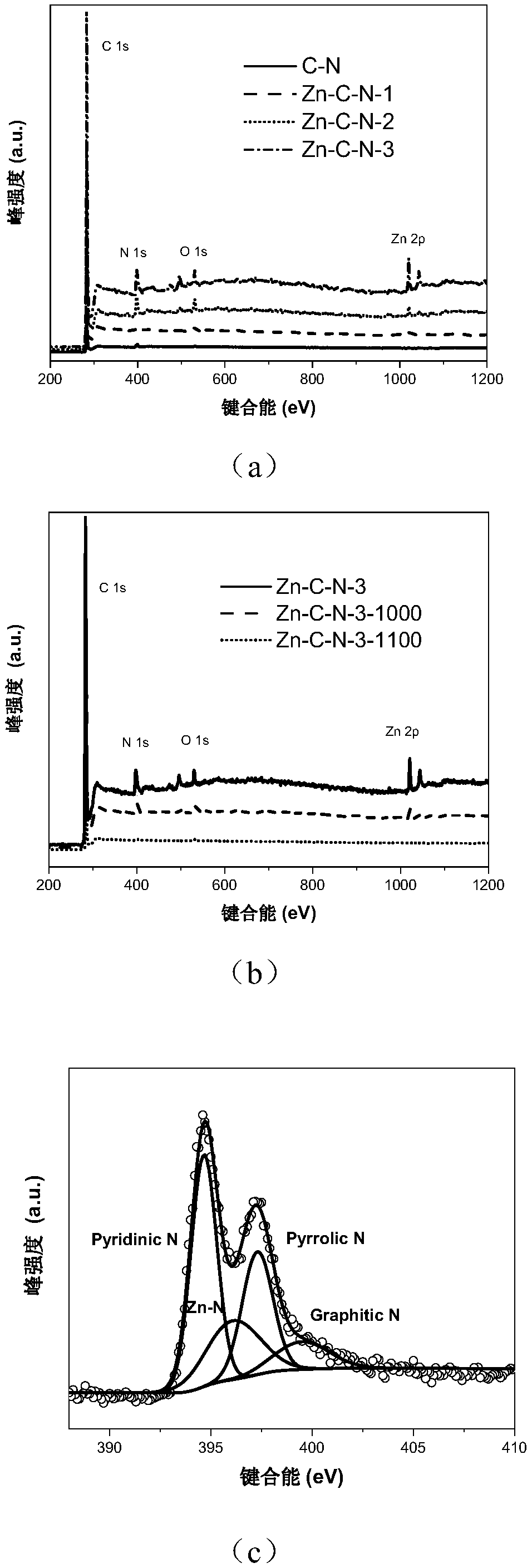

[0031] The preparation method of the present invention includes the following two steps: step 1, adding carbon source, zinc source and inducer to deionized water, stirring and mixing, and obtaining a precursor after drying; step 2, high-temperature carbonization: the precursor obtained in step 1 Carry out high temperature carbonization under inert atmosphere.

[0032] In step (1), described carbon source is urea; Zinc source is zinc nitrate, zinc sulfate or zinc acetate; Inducing agent is citric acid; The mol ratio of zinc source and carbon source is 1:(10 3 -10 4 ); Stirring was carried out at 20-30°C for 2-4h.

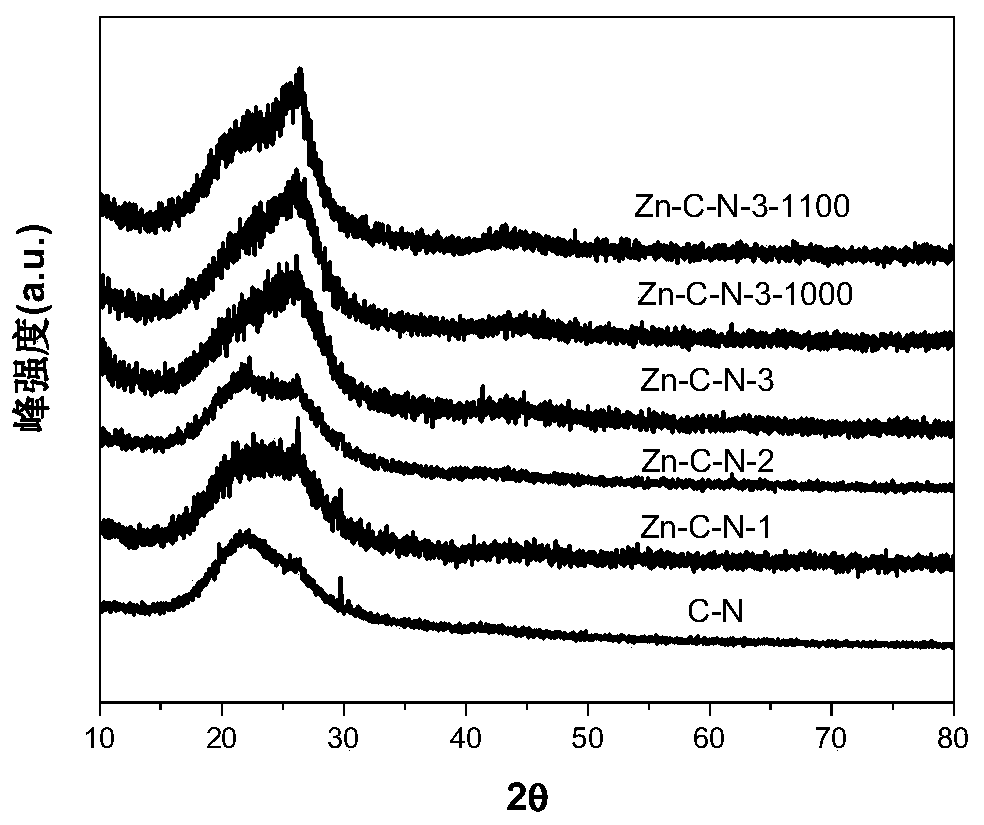

[0033] In step (2), carbonization is divided into two processes, the first process carbonization temperature is 500-600 ℃, time is 1-2h; the second process carbonization temperature is 900-1100 ℃, time is 1-2h; The inert atmosphere mentioned above is argon.

[0034] The present invention also provides the application of the above-mentioned catalyst material in the...

Embodiment 1

[0045] 1. Weigh 0.026g of zinc nitrate hexahydrate, 0.36g of citric acid monohydrate, and 10g of urea in 15mL of deionized water and stir for 2 hours. After stirring evenly, transfer to an oven and dry at 80°C;

[0046] 2. Grind the dry material and place it in a corundum boat, then transfer it to a tube furnace for calcination. Under an argon atmosphere, first raise the temperature to 550°C and keep it for 2h, then raise the temperature to 900°C and keep it for 1h. The obtained catalyst is designated as Zn-C-N-2.

Embodiment 2

[0048] 1. Weigh 0.005g of zinc nitrate hexahydrate, 0.36g of citric acid monohydrate, and 10g of urea in 15mL of deionized water and stir for 2 hours. After stirring evenly, transfer to an oven and dry at 80°C;

[0049] 2. Grind the dry material and place it in a corundum boat, then transfer it to a tube furnace for calcination. Under an argon atmosphere, first raise the temperature to 550°C and keep for 2h, then raise the temperature to 900°C and keep for 1h, and the obtained catalyst is designated as Zn-C-N-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com