Metal powder hole-adding and reinforcing type sintering equipment

A technology of metal powder and sintering equipment, applied in the field of sintering, can solve the problems of low overall strength, accidental fragmentation, and affecting the filtering effect of filter elements, etc., and achieve the effects of good filtering effect, increased strength, and improved structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

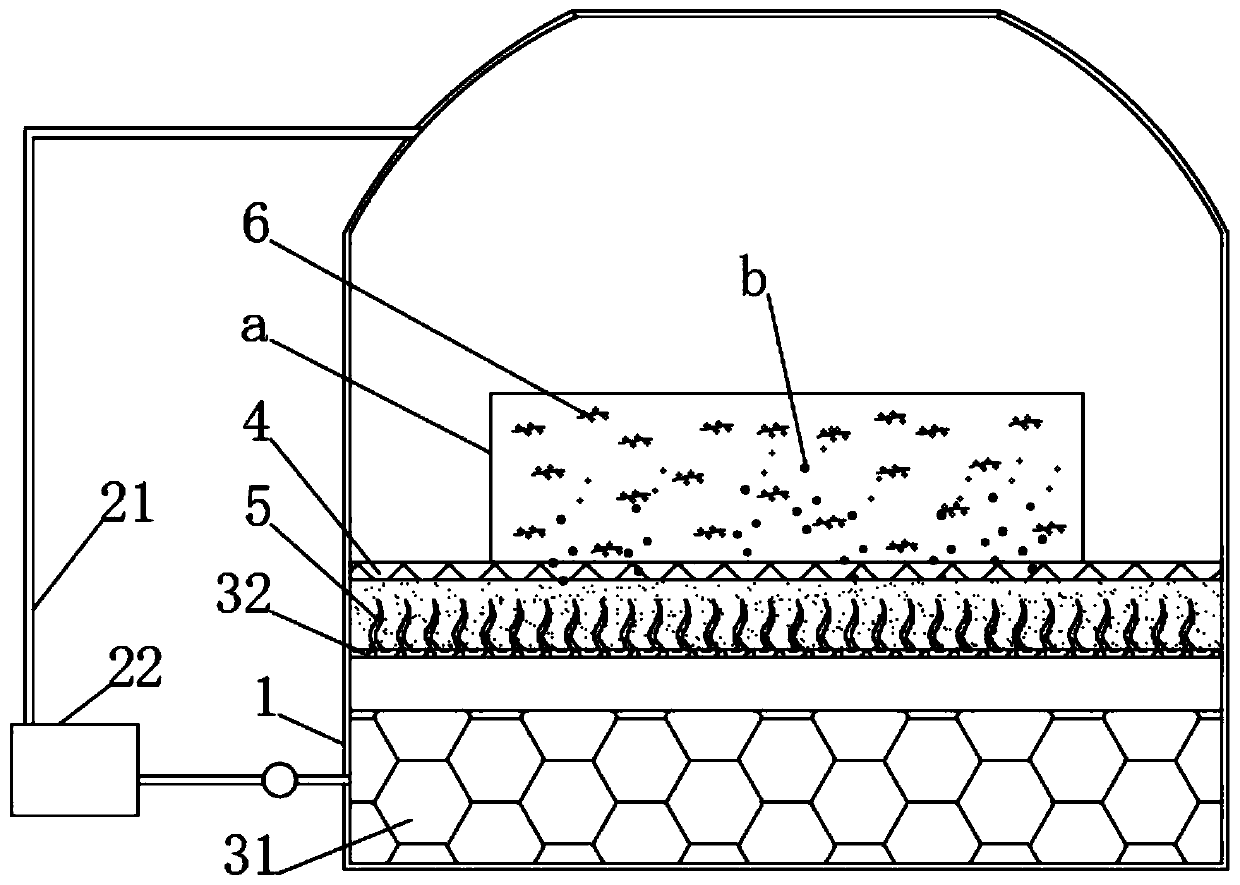

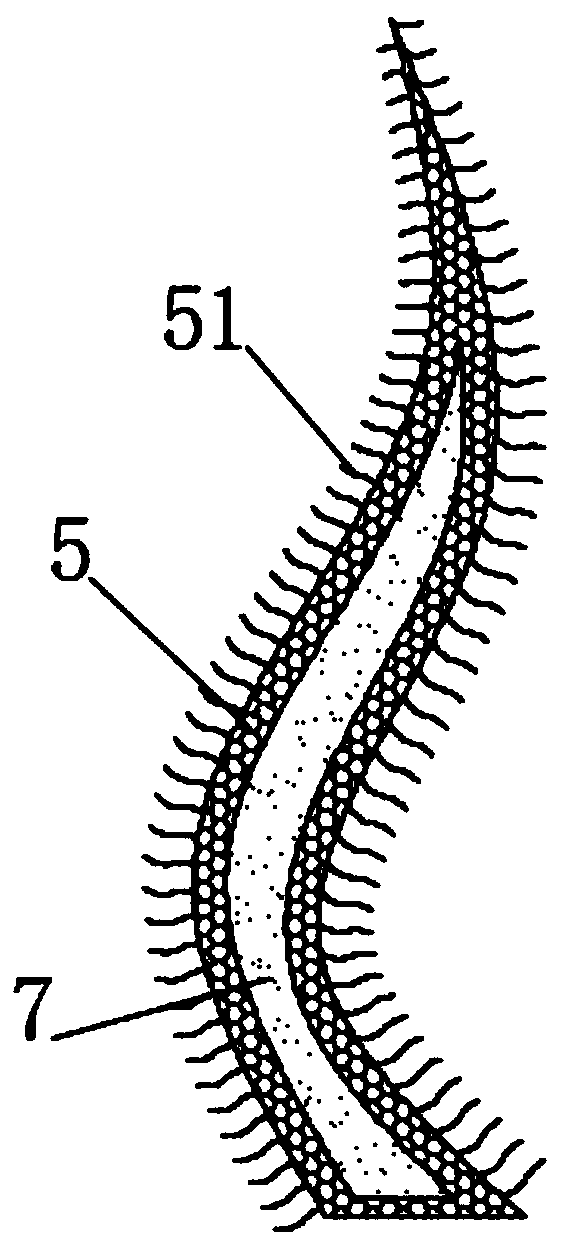

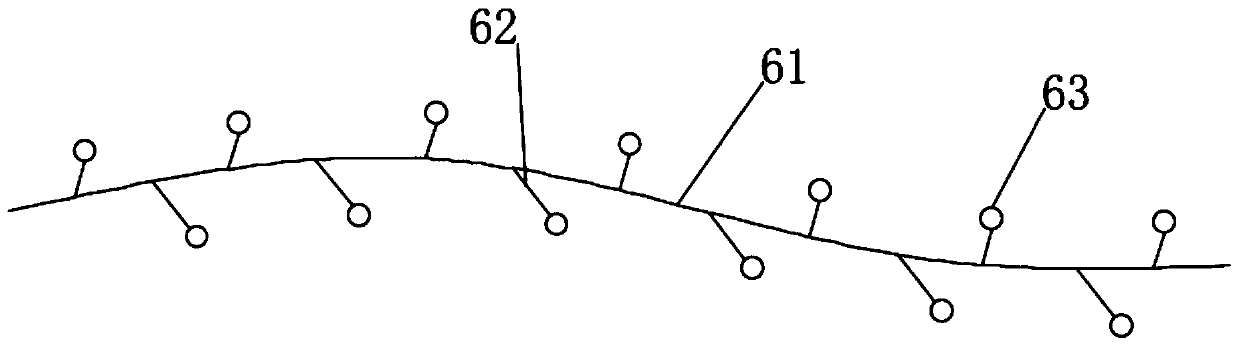

[0039] see figure 1 , a sintering device with metal powder plus holes and reinforcement, including a device body 1, an air hole layer 31 is fixedly connected to the inner bottom of the device body 1, a partition 32 and a bearing plate 4 are fixedly connected to the middle of the device body 1, and the carrier plate 4 is located on the partition 32, the upper end of the equipment body 1 is connected with a gasification circulation mechanism, and the gasification circulation mechanism includes a communication pipe 21 fixedly connected with the equipment body 1. 21 The lower end runs through the device body 1 and communicates with the air hole layer 31. The end near the air hole layer 31 is equipped with a condensate tank 22 with distilled water and an atomizer in sequence from left to right. Pressed metal powder is placed on the top of the carrier plate 4. The metal powder plate is evenly inlaid with a plurality of evenly distributed embedded hole-adding reinforcement chains 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com