Controllable synthesis method of pure silicon and high-silicon CHA molecular sieves

A synthesis method and molecular sieve technology, applied in the fields of crystalline aluminosilicate zeolite, bulk chemical production, ethylene production, etc., can solve problems such as poor uniformity, difficulty in controlling particle size and distribution, complicated mother liquor preparation process, etc., and achieve reduction of raw materials Cost, wide particle size distribution, and the effect of simplifying the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

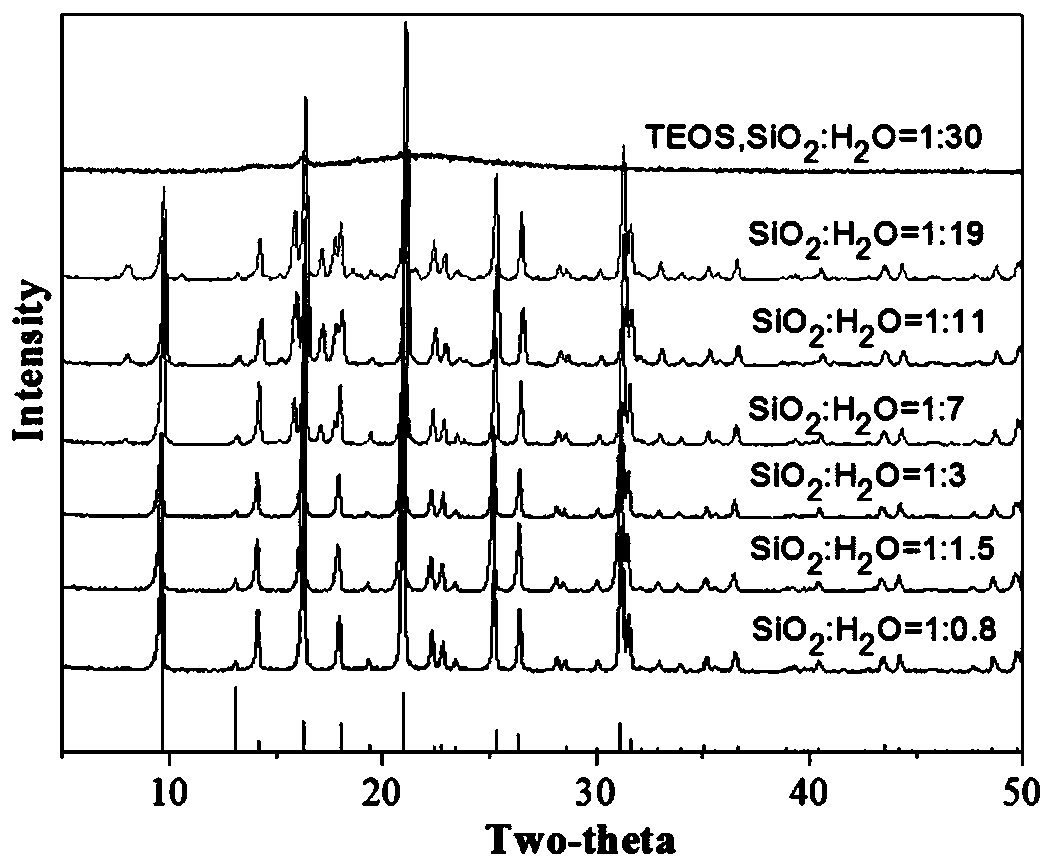

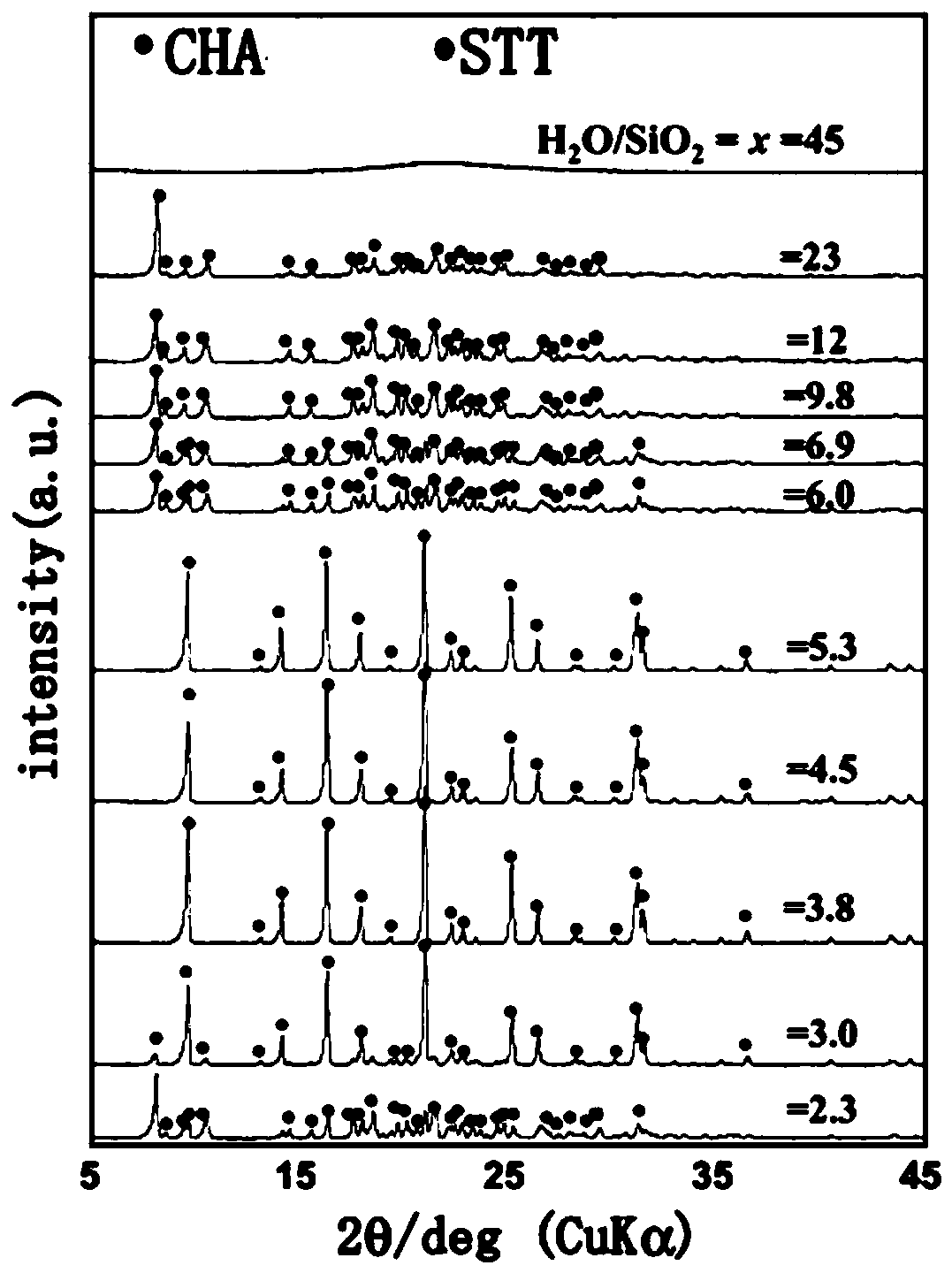

[0058] Various embodiments relate to a method for the controllable synthesis of pure silicon and high silicon CHA molecular sieves. Using traditional N,N,N-trimethyl-1-adamantyl ammonium hydroxide (TMAdaOH) as the template, using ammonium hexafluorosilicate, or a mixture of common silicon sources and fluorides as the silicon source, in H 2 O / SiO 2 Pure silicon and high-silicon CHA molecular sieves are efficiently and rapidly synthesized in a dilute solution of about 30 to achieve effective regulation of crystal size and reduce the amount of templates used. Specifically include the following steps:

[0059] (1) Perform ball milling on the pure silicon CHA molecular sieve crystal seed crystals. After ball milling, the molecular sieve crystals obtained from the CHA nanocrystal seeds are deeply fragmented and amorphized, and what are obtained are fine CHA molecular sieve crystals and amorphous particles. All smaller than 100 nanometers, or even smaller;

[0060] (2) After mixin...

Embodiment 1

[0068] Embodiment 1, this embodiment aims at synthesizing a kind of all silicon CHA molecular sieve

[0069] A controllable synthesis method of pure silicon CHA molecular sieve, the specific steps are as follows:

[0070] Step 1: Mix ethyl orthosilicate and N,N,N-trimethyl-1-adamantyl ammonium hydroxide, stir for 4 hours, then place in an oven at 80 degrees Celsius to remove excess water and ethanol, then Add hydrofluoric acid, stir to obtain the seed crystal synthesis mother liquor, the SiO in the mother liquor 2 , HF, trimethyladamantyl ammonium hydroxide (TMAdaOH) and H 2 The molar ratio of O is 1.0:0.5:0.5:3. Crystallize at 453K for 48 hours to obtain pure silicon CHA molecular sieve seeds. The molecular sieve seed crystals are relatively large, about 8 microns. After being ball-milled by a ball mill, the crystals are pulverized to below 500 nanometers;

[0071] Step 2: Mix ethylenediamine (EDA), organic template N,N,N-trimethyl-1-adamantyl ammonium hydroxide (TMAdaOH...

Embodiment 2

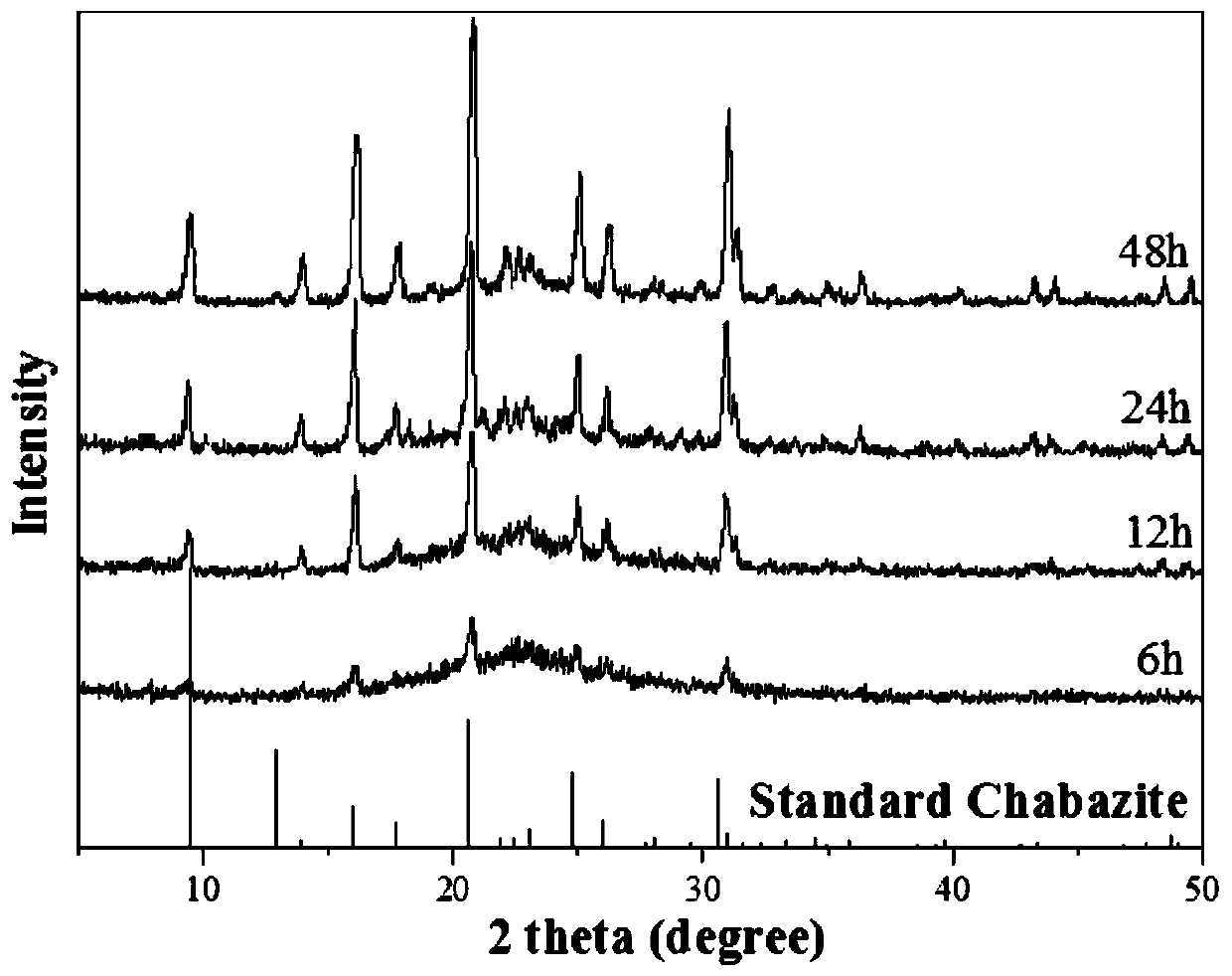

[0076] The difference from Example 1 is that in step 4, crystallization was carried out at 433K for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com