Method for removing heavy metals in organic sludge by slurrying

An organic sludge and heavy metal technology, applied in chemical instruments and methods, dehydration/drying/concentrated sludge treatment, organic fertilizers, etc., can solve problems such as unfavorable plant growth and development, danger, and inability to solve heavy metal pollution in sludge, and achieve Realize the effect of mass production and treatment, easy operation and comprehensive utilization of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

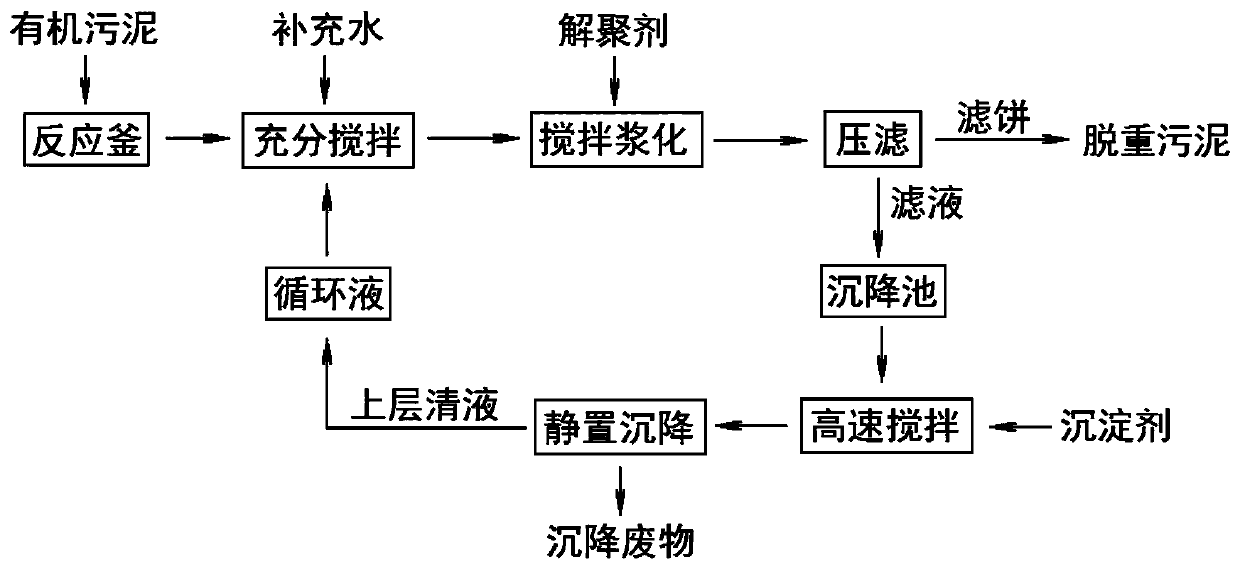

Method used

Image

Examples

Embodiment 1

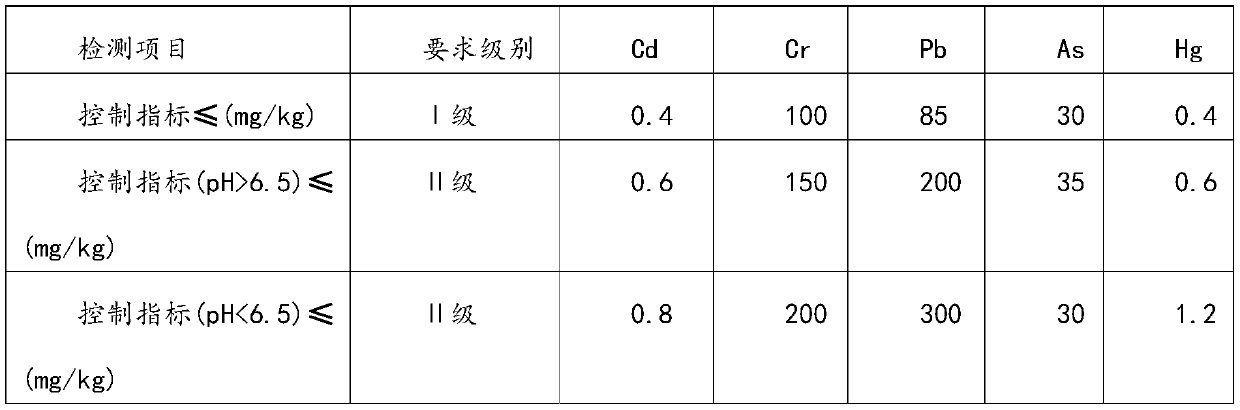

[0040] Add 10 tons of organic sludge with a moisture content of 80% into the reactor and 10m 3 The circulating liquid is fully stirred and mixed to form a suspension, and then 85L of iron-containing waste liquid (density 1.18g / ml) with a concentration of 20% is added, and fully stirred to completely and evenly mix with the organic sludge until it is completely slurried to form a slurry; Send the slurry to the X20 reinforced polypropylene filter press for pressure filtration, and the filter cake is the product - de-heavy sludge, with a moisture content of 80%, a pH value of 6.8, and the test results of five kinds of strictly controlled heavy metal contents are shown in Table 2, completely Reach the I-level standard of the control index. Add 8.8L concentration of 20% sulfur-containing waste liquid (density 1.14g / ml) after the obtained filtrate is pumped to the settling tank as a precipitating agent, stir at high speed to fully react the precipitating agent and the filtrate; let ...

Embodiment 2

[0044] Add 10 tons of organic sludge with a moisture content of 80% into the reactor and 10m 3 The circulating liquid is fully stirred and mixed to form a suspension, and then 85L of iron-containing waste liquid (density 1.18g / ml) with a concentration of 20% is added, and fully stirred to completely and evenly mix with the organic sludge until it is completely slurried to form a slurry; Send the slurry to the X20 type polypropylene filter press for pressure filtration, and the filter cake is the product - de-heavy sludge, with a moisture content of 80%, a pH value of 6.8, and the test results of five kinds of strictly controlled heavy metal contents are shown in Table 3, completely Reach the I-level standard of the control index. After the obtained filtrate is pumped to the settling tank, add 11.9L of 15% sulfur-containing waste liquid (density 1.12g / ml) as a precipitant, stir at a high speed to fully react the precipitant and the filtrate; let it settle for 24 hours, and pump...

Embodiment 3

[0048] Add 10 tons of organic sludge with a water content of 80% (the Cd content in this batch of raw materials is relatively high) into the reactor and 10m 3 The circulating liquid is fully stirred and mixed to form a suspension, and then 116L of iron-containing waste liquid with a concentration of 20% (density 1.14g / ml) is added, and fully stirred to completely and evenly mix with the organic sludge until it is completely slurried to form a slurry; The slurry is sent to the X20 type polypropylene filter press for pressure filtration, and the obtained filter cake is returned to the reactor, and the second heavy metal removal treatment is also carried out, and the filter cake of the second pressure filtration is used as the product - heavy sludge removal , moisture content 80%, pH value 6.8, measured 5 kinds of strictly controlled heavy metals twice and removed heavy metal content respectively as shown in Table 4, and finally completely reached the I level standard of the contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com