Device and process for comprehensive utilization and resourceful treatment of impurity-containing ammonium chloride wastewater

A ammonium chloride and recycling technology, applied in multi-stage water treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of high energy consumption for evaporation and crystallization, excessive impurities in ammonium chloride by-products, and high operating costs problems, achieve major social and economic benefits, and realize the effect of comprehensive utilization of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

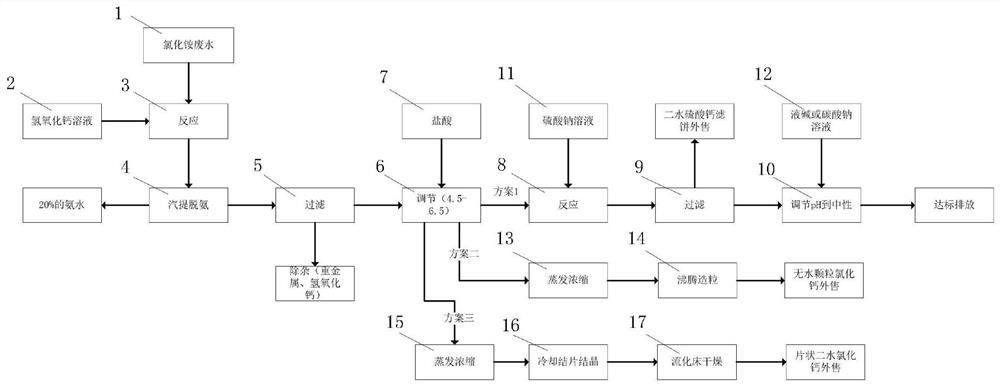

[0065] Embodiment 1, a kind of comprehensive utilization of the ammonium chloride waste water containing impurity and the device of resource treatment, such as figure 1 as shown,

[0066] It includes a waste water storage tank 1, a calcium hydroxide storage tank 2, a first reaction device 3, a stripping deamination device 4, a first filtration device 5, a first pH adjustment device 6, a hydrochloric acid storage tank 7, a second reaction device 8, The second filtering device 9, the second pH adjusting device 10, sodium sulfate storage tank 11, alkaline solution storage tank 12, the first evaporative concentration device 13, boiling granulation device 14, the second evaporative concentration device 15, cooling crystallization device 16 and Drying device 17.

[0067] Wastewater storage tank 1 is used for storing the waste water containing ammonium chloride mass fraction 0.5-15%;

[0068] Calcium hydroxide storage tank 2 is used for storing the calcium hydroxide solution of mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com