Oil sludge treatment device and system

A kind of technology of sludge and inner casing, which is applied in the direction of pyrolysis sludge, sludge treatment, water/sludge/sewage treatment, etc., can solve the problem that sludge is not easy to decompose and decompose, energy consumption and other problems, and achieves the solution of difficult Effects of treatment, meeting environmental protection requirements, and safe treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

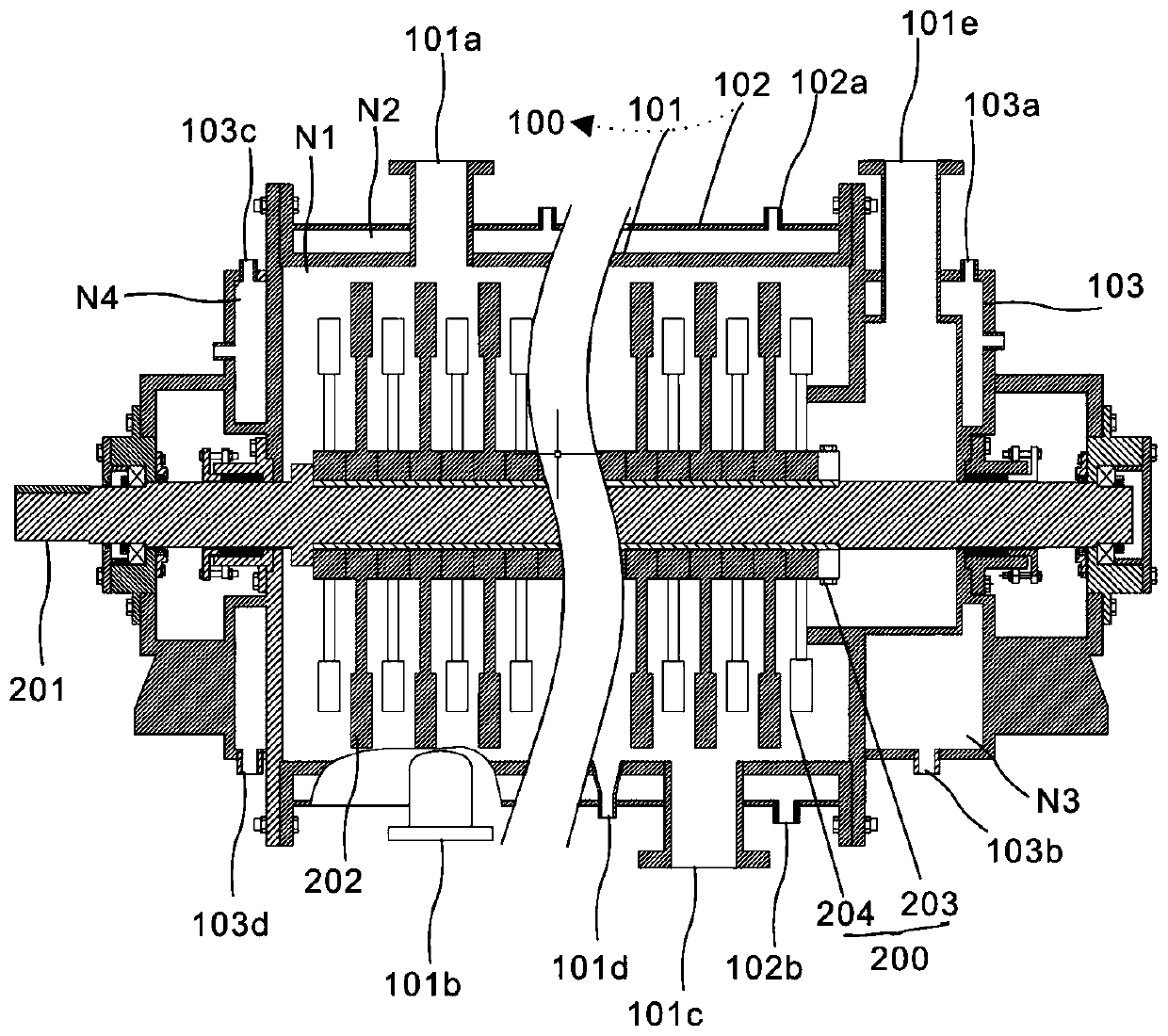

[0041] refer to figure 1 , providing a schematic diagram of the overall structure of a sewage sludge treatment device and system, such as figure 1 , a device and system for treating sewage sludge includes a bearing assembly 100, including an inner casing 101, an outer casing 102 disposed on the periphery of the inner casing 101, and spacers 103 located on both sides of the inner casing 101; and, a hammer mill assembly 200 , comprising a rotating shaft 201 and a first rotor member 202 and a second rotor member 204 arranged alternately on the rotating shaft 201 through locking members 203, the first rotor member 202 and the second rotor member 204 are both in the reaction chamber of the housing 101 within N1.

[0042]Specifically, the main structure of the present invention includes a bearing assembly 100 and a hammer mill assembly 200. Through the mutual cooperation between the bearing assembly 100 and the hammer mill assembly 200, the sludge can be fully mixed, sheared and he...

Embodiment 2

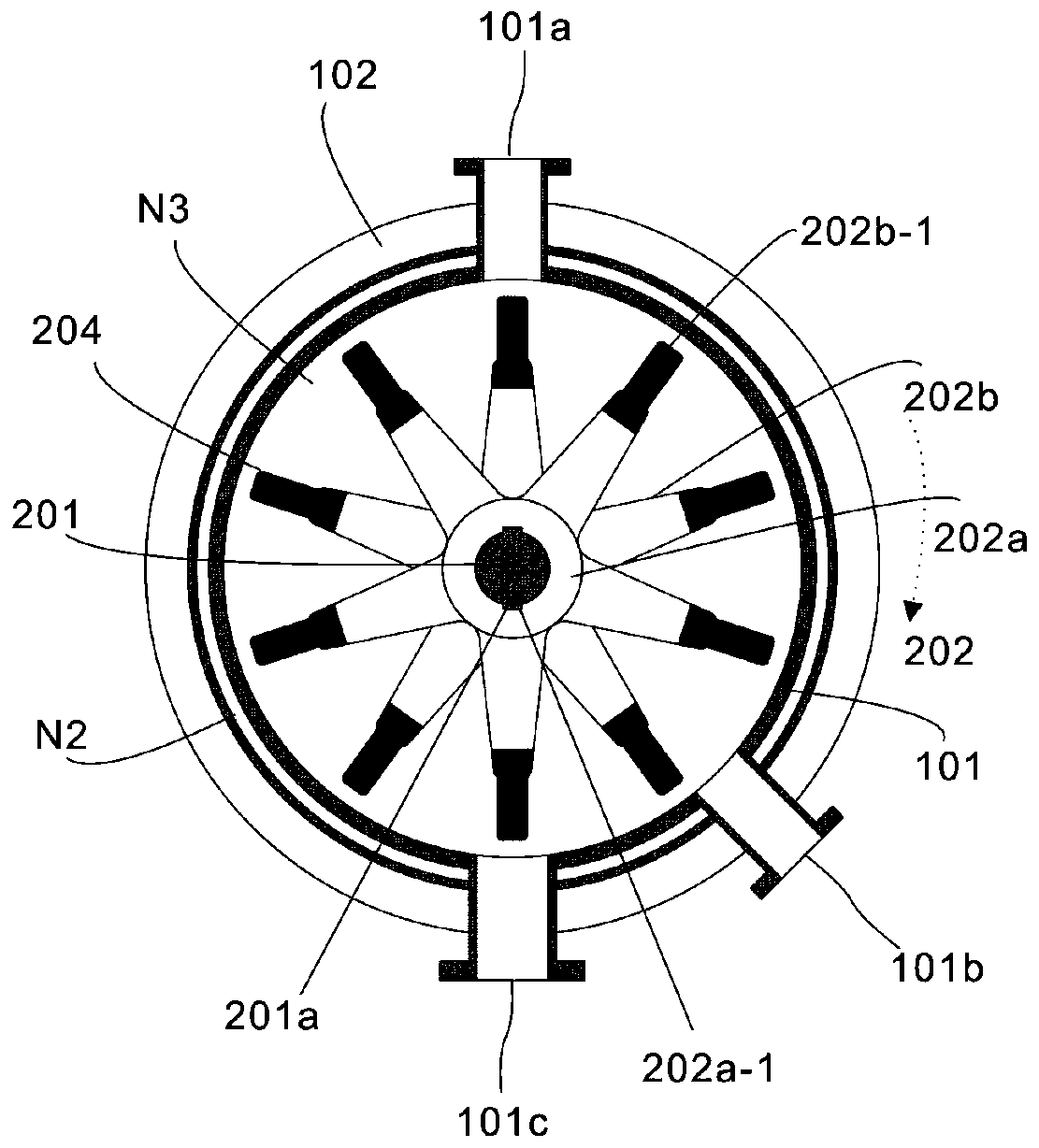

[0048] refer to figure 2 , this embodiment is different from the first embodiment in that: the first rotor parts 202 and the second rotor parts 204 have the same structure and are staggered on the rotating shaft 201, and the staggered first rotor parts 202 and the second rotor parts 204 It is conducive to uniform hammer grinding and can improve the decomposition efficiency. Specifically, the first rotor part 202 and the second rotor part 204 have the same structure and are arranged alternately on the rotating shaft 201. It should be emphasized that not only two sets of rotor parts are installed on the rotating shaft 201, but also several The rotor groups are arranged side by side, and the adjacent rotor parts are staggered at a certain angle. According to the required amount of sludge treatment, 12 to 36 groups of rotor parts are arranged axially along the rotating shaft 201. Preferably, several groups of rotor parts adopt double The method of flat key connection (or spline ...

Embodiment 3

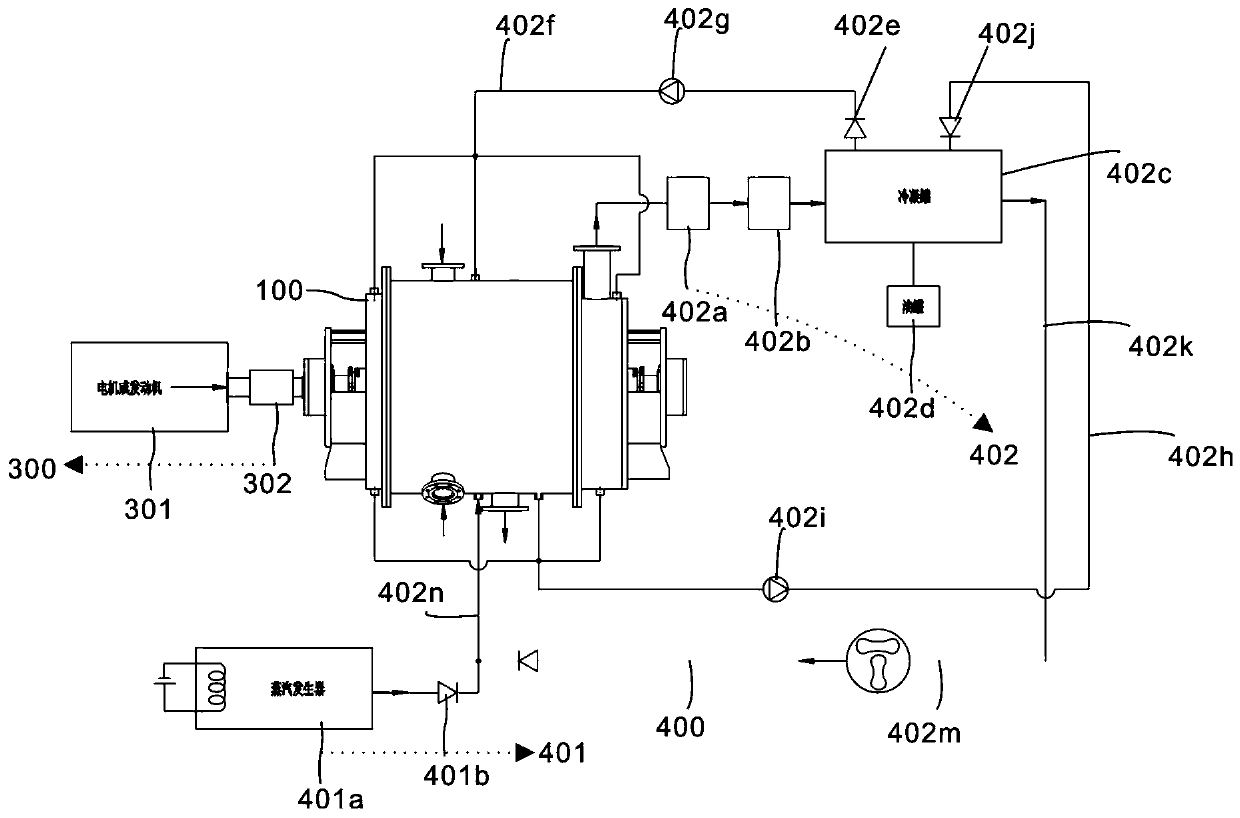

[0053] refer to image 3 , this embodiment is different from the above embodiments in that: this embodiment is a sludge treatment system, which includes a bearing assembly 100, a hammer mill assembly 200, a driving assembly 300, and a heating assembly 400, and the set bearing assembly 100, hammer The mutual cooperation between the grinding assembly 200, the driving assembly 300 and the heating assembly 400 enables the injection of steam, which greatly reduces the evaporation temperature of the oil, improves the processing efficiency, and solves the problem that the fine hammer mill dust is difficult to handle. The reduction has improved the service life of the mechanical structure, enhanced the stability of operation, and can handle oily sludge in a more green, energy-saving, efficient, stable and safe manner, meeting the environmental protection requirements of future development. Specifically, a decomposition reaction chamber and a heating decomposition chamber of sludge are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com