Herbicide dimethylamine salt and preparation method thereof

A technology of dimethylamine salt and herbicide, which is applied in the field of herbicide dimethylamine salt and its preparation, can solve the problems of difficult removal of water, unfriendly environment, long process time, etc. It is easy to control the end point of the reaction, The effect of convenient separation and purification and safe physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

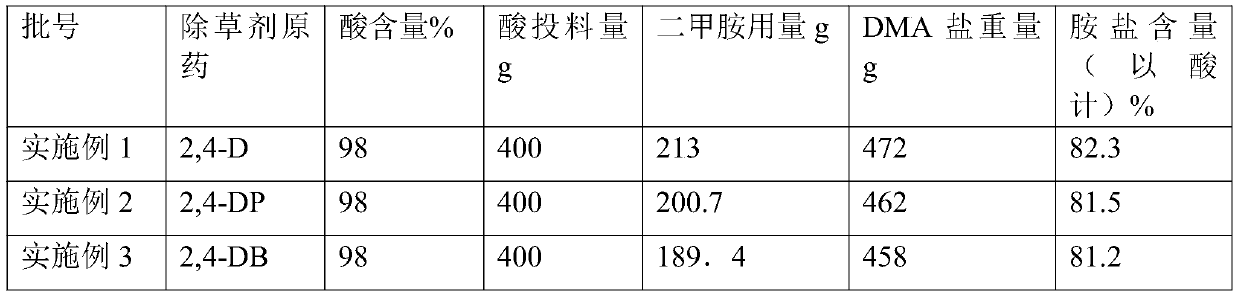

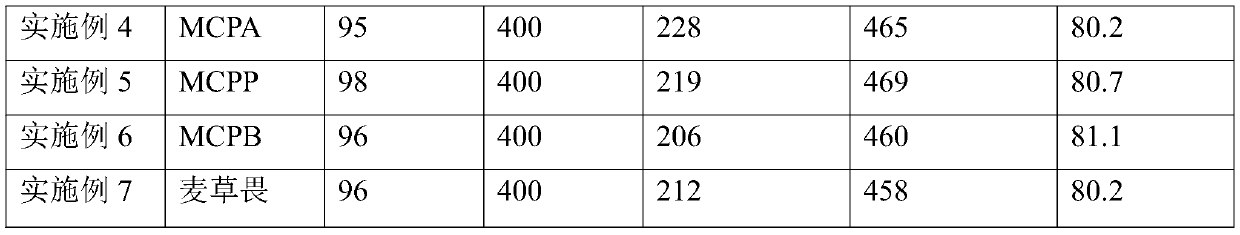

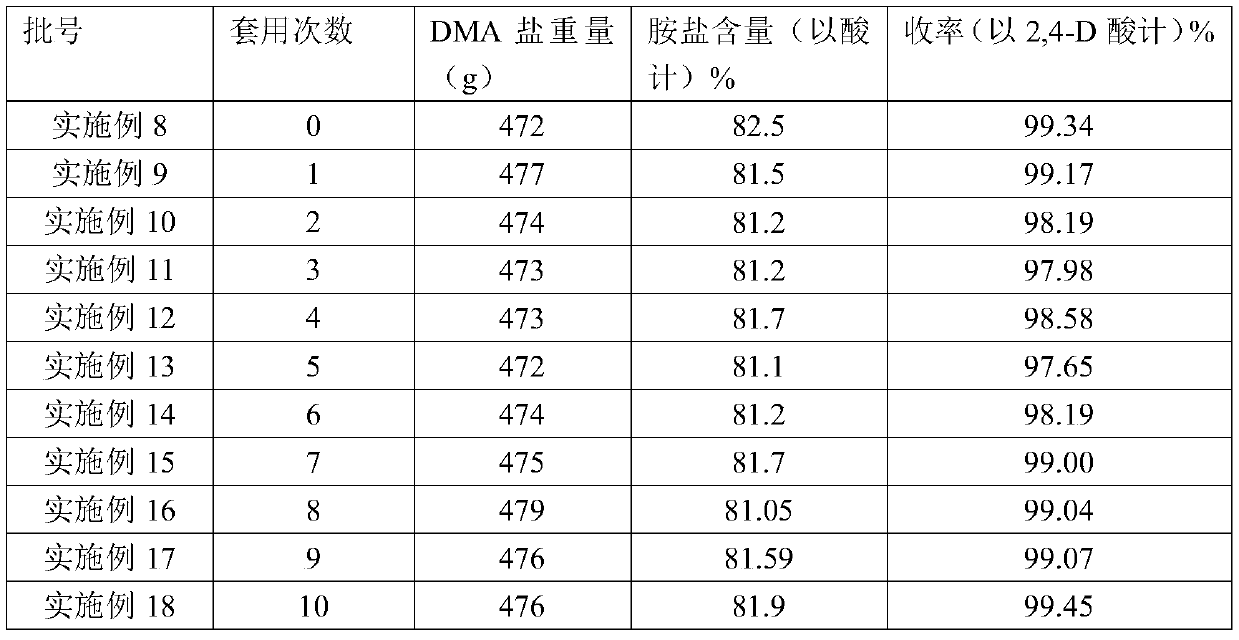

Examples

Embodiment 1

[0024] (1) Get the herbicide, place it in a four-necked flask equipped with a pH meter, add an organic solvent to dissolve it, drop the temperature to 30°C, add 40% dimethylamine solution dropwise, and keep the temperature for 1 hour after the dropwise addition. The holding temperature is 50°C, the pH value is controlled at 9, and the pH value is maintained for 1 hour;

[0025] (2) Use the reflux dehydration technology under negative pressure, control the vacuum degree at -0.086~-0.088MPa, raise the dehydration temperature to 55~60°C, until no water comes out, then lower the temperature to 45°C, precipitate crystals, stir for 1 hour, Then lower the temperature to 25° C., filter, collect the precipitate, and dry at 50° C. to obtain the dimethylamine salt.

[0026] The raw material adopted in the present embodiment comprises herbicide, dimethylamine aqueous solution and organic solvent; Herbicide is 2,4-dichlorophenoxyacetic acid, and organic solvent is toluene, and the mol rati...

Embodiment 2

[0028] (1) Get the herbicide, place it in a four-necked flask equipped with a pH meter, add an organic solvent to dissolve it, drop the temperature to 30°C, add 40% dimethylamine solution dropwise, and keep the temperature for 1 hour after the dropwise addition. The holding temperature is 50°C, the pH value is controlled at 9, and the pH value is maintained for 1 hour;

[0029] (2) Use the reflux dehydration technology under negative pressure, control the vacuum degree at -0.086~-0.088MPa, raise the dehydration temperature to 60°C until no water comes out, then cool down to 45°C, precipitate crystals, stir for 1 hour, and then cool down Centrifuge at 25°C, collect the precipitate, and dry at 50°C to obtain the dimethylamine salt.

[0030] The raw material adopted in the present embodiment comprises herbicide, dimethylamine aqueous solution and organic solvent; Herbicide is 2,4-dichlorophenoxypropionic acid, and organic solvent is toluene, and the mol ratio of herbicide and dim...

Embodiment 3

[0032] (1) Get the herbicide, place it in a four-necked flask equipped with a pH meter, add an organic solvent to dissolve it, drop the temperature to 30°C, add 40% dimethylamine solution dropwise, and keep the temperature for 1 hour after the dropwise addition. The holding temperature is 50°C, the pH value is controlled at 9, and the pH value is maintained for 1 hour;

[0033] (2) Use the reflux dehydration technology under negative pressure, control the vacuum degree at -0.086~0.088MPa, raise the dehydration temperature to 60°C until no water comes out, then cool down to 45°C, precipitate crystals, stir for 1 hour, and then cool down to Centrifuge at 25°C, collect the precipitate, and dry at 50°C to obtain the dimethylamine salt.

[0034] The raw materials adopted in this embodiment include herbicide, dimethylamine aqueous solution and organic solvent; : 1.07; The weight ratio of described herbicide and organic solvent is 1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com