Preparation method of anti-dry and anti-freezing hydrogel

A technology of gel and frozen water, which is applied in the direction of analyzing materials through chemical reactions and observing the influence of chemical indicators. It can solve the problems of limited use and achieve uniform distribution, short experiment period, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

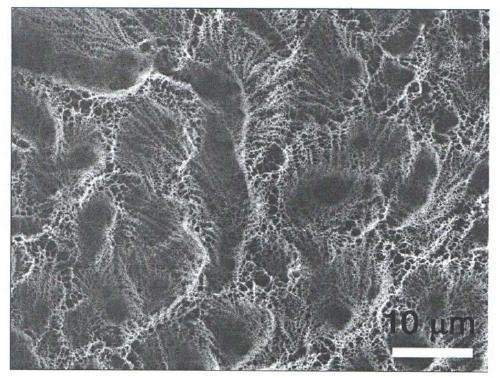

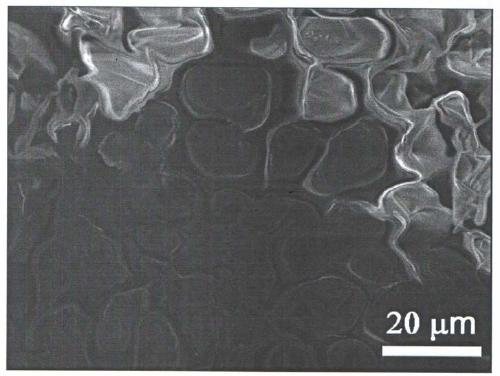

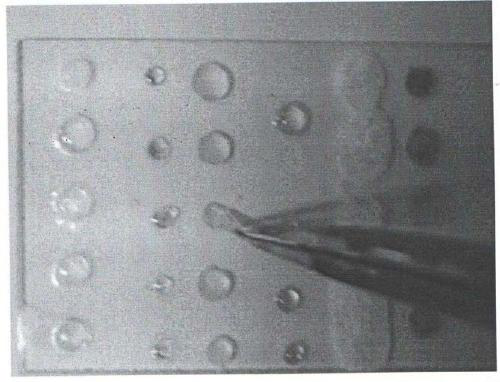

Image

Examples

Embodiment 1

[0027] a. Dissolving acrylamide monomer in solvent water to prepare acrylamide monomer solution with a mass fraction of 1%;

[0028] b. Dissolving the cross-linking agent N,N'-methylenebisacrylamide in water to form a N,N'-methylenebisacrylamide crosslinking agent solution with a mass fraction of 1g / L;

[0029] c. Under magnetic stirring, drop 784 μl of the N,N'-methylenebisacrylamide crosslinking agent solution obtained in step b into 20 ml of the acrylamide monomer solution obtained in step a, keep stirring for 10 minutes, and add acrylamide 0.1% initiator tetramethylethylenediammonium based on monomer mass fraction and 0.1% additive clay based on acrylamide monomer mass fraction, continue stirring for 20 minutes, then add acrylamide monomer mass fraction 1% of moisturizing molecular sulfuric acid;

[0030] d. According to the addition of tetramethylethylenediammonium initiator, select the ultraviolet light with a wavelength of 365nm for 30 minutes to carry out photopolymer...

Embodiment 2

[0033] a. Dissolving the N-(isobutoxy)methacrylamide monomer in a solvent to form a 50% N-(isobutoxy)methacrylamide monomer solution by mass fraction;

[0034] b. Dissolving the N,N'-diisopropylcarbodiimide crosslinking agent in water to form a N,N'-diisopropylcarbodiimide crosslinking agent solution with a mass fraction of 20g / L;

[0035] c. Under magnetic stirring, drop 784 μl of the N,N'-diisopropylcarbodiimide crosslinking agent solution obtained in step b into the N-(isobutoxy)methacrylamide monomer obtained in step a In 20ml of the solution, keep stirring for 10min, add 1% ammonium persulfate initiator based on the mass fraction of N-(isobutoxy)methacrylamide monomer and N-(isobutoxy)methacrylamide 10% polyethylene glycol (PEG) additive based on the mass fraction of the amide monomer, after continuing to stir for 20 minutes, add 40% of the moisturizing agent based on the mass fraction of N-(isobutoxy) methacrylamide monomer sex molecule phosphoric acid;

[0036] d. Acc...

Embodiment 3

[0039] a. Dissolving the methacrylamide monomer in a solvent to prepare a methacrylamide monomer solution with a mass fraction of 10%;

[0040] b. Dissolving the N,N'-methylenebisacrylamide crosslinking agent in water to form a N,N'-methylenebisacrylamide crosslinking agent solution with a mass fraction of 12g / L;

[0041] c. Under magnetic stirring, drop 784 μl of the N,N'-methylenebisacrylamide crosslinking agent solution obtained in step b into 20 ml of the methacrylamide monomer solution obtained in step a, keep stirring for 10 minutes, and add 1% sodium bisulfite initiator based on the mass fraction of methacrylamide monomer and 8% polyvinyl alcohol (PVA) additive based on the mass fraction of methacrylamide monomer, after continuing to stir for 20min, add 20% moisturizing molecular acrylic acid based on the mass fraction of methacrylamide monomer;

[0042] d. According to the addition of sodium bisulfite initiator, select a UV light with a wavelength of 254nm to illuminate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com