Preparation method of printable high-strength body temperature release drug hydrogel

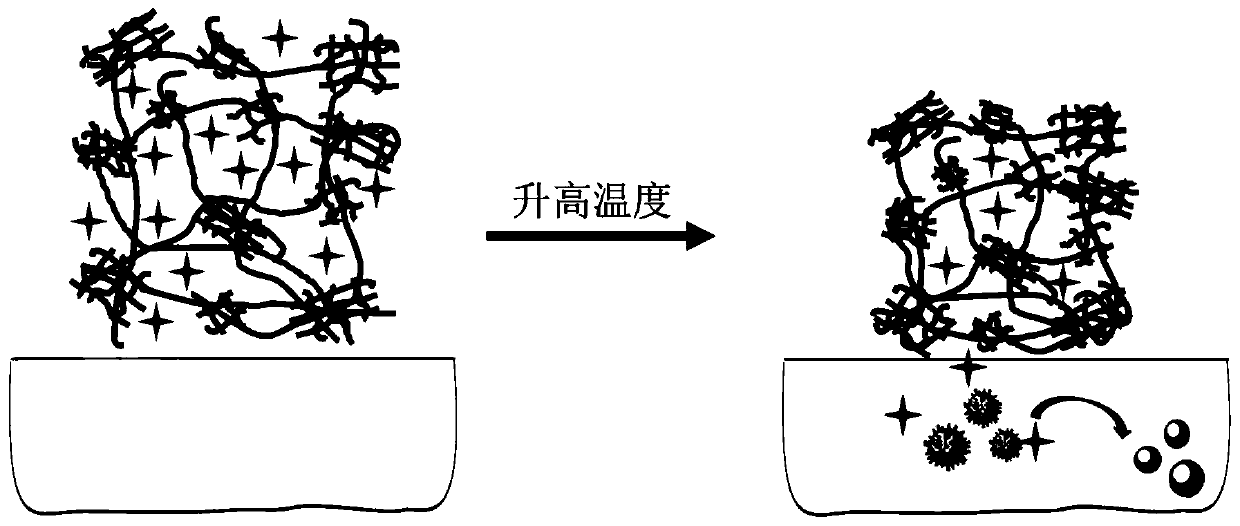

A hydrogel, high-strength technology, applied in medical science, bandages, additive processing, etc., can solve the problems of poor biocompatibility, poor mechanical properties, lack of hydrogel, etc., and achieve a tight network and enhanced hydrophobicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

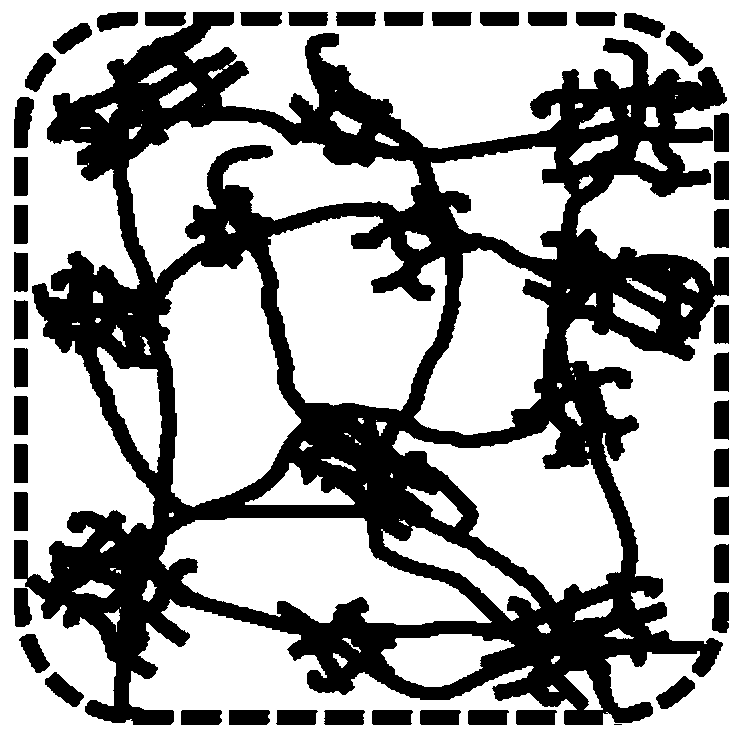

[0035] Step 1): Weigh 2.0725g AMPS (1mol / L), 0.4g NaOH (1mol / L), 0.0616g MBAA (0.04mol / L) and 0.0015g KA (0.001mol / L) respectively in a beaker, add 10mL Deionized water, stirred evenly to obtain a transparent solution. The solution is poured into a glass mold, and placed under a high-pressure mercury lamp with a power of 200-500W at 10-30 cm for 7-10 hours to obtain PNaAMPS hydrogel.

[0036] Step 2): The hydrogel prepared in step (1) was dried in a vacuum oven at 80° C. to constant weight, ground and sieved to obtain PNaAMPS powder with a particle size of 10-200 μm.

[0037] Step 3): Weigh 0.15g PNaAMPS (0.015g / mL), 0.5658g NIPAM (0.5mol / L), 2.4878gAAm (3.5mol / L), 0.0154g MBAA (0.01mol / L) and 0.0015g KA (0.001 mol / L) into a beaker, add 10 mL of deionized water, stir evenly to obtain a translucent solution.

[0038] Step 4): Pour the solution obtained in step (3) into a glass mold, place it under a high-pressure mercury lamp with a power of 200-500W at 10-30cm for 7-10 hours...

Embodiment 2

[0045] Step 1): Weigh 2.0725g AMPS (1mol / L), 0.4g NaOH (1mol / L), 0.0616g MBAA (0.04mol / L) and 0.0015g KA (0.001mol / L) respectively in a beaker, add 10mL Deionized water, stirred evenly to obtain a transparent solution. The solution is poured into a glass mold, and placed under a high-pressure mercury lamp with a power of 200-500W at 10-30 cm for 7-10 hours to obtain PNaAMPS hydrogel.

[0046] Step 2): The hydrogel prepared in step (1) was dried in a vacuum oven at 80° C. to constant weight, ground and sieved to obtain PNaAMPS powder with a particle size of 10-200 μm.

[0047] Step 3): Weigh 0.15g PNaAMPS (0.015g / mL), 1.1316g NIPAM (1mol / L), 2.1324g AAm (3mol / L), 0.0154g MBAA (0.01mol / L) and 0.0015g KA (0.001mol / L) In a beaker, add 10 mL of deionized water, stir evenly to obtain a translucent solution.

[0048] Step 4): Pour the solution obtained in step (3) into a glass mold, place it under a high-pressure mercury lamp with a power of 200-500W at 10-30cm for 7-10 hours, and...

Embodiment 3

[0055] Step 1): Weigh 2.0725g AMPS (1mol / L), 0.4g NaOH (1mol / L), 0.0616g MBAA (0.04mol / L) and 0.0015g KA (0.001mol / L) respectively in a beaker, add 10mL Deionized water, stirred evenly to obtain a transparent solution. The solution is poured into a glass mold, and placed under a high-pressure mercury lamp with a power of 200-500W at 10-30 cm for 7-10 hours to obtain PNaAMPS hydrogel.

[0056] Step 2): The hydrogel prepared in step (1) was dried in a vacuum oven at 80° C. to constant weight, ground and sieved to obtain PNaAMPS powder with a particle size of 10-200 μm.

[0057] Step 3): Weigh 0.15g PNaAMPS (0.015g / mL), 1.6974g NIPAM (1.5mol / L), 1.7770gAAm (2.5mol / L), 0.0154g MBAA (0.01mol / L) and 0.0015g KA (0.001 mol / L) into a beaker, add 10 mL of deionized water, stir evenly to obtain a translucent solution.

[0058] Step 4): Pour the solution obtained in step (3) into a glass mold, place it under a high-pressure mercury lamp with a power of 200-500W at 10-30cm for 7-10 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com