Core-shell structure nano crystal and preparation method thereof

A core-shell structure, nanocrystal technology, applied in nanotechnology, nanotechnology, nanooptics, etc., can solve the problems of difficult control of nanocrystal particle size, unfavorable to improve the color gamut of display devices, and large half-peak width of nanocrystal emission peak.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

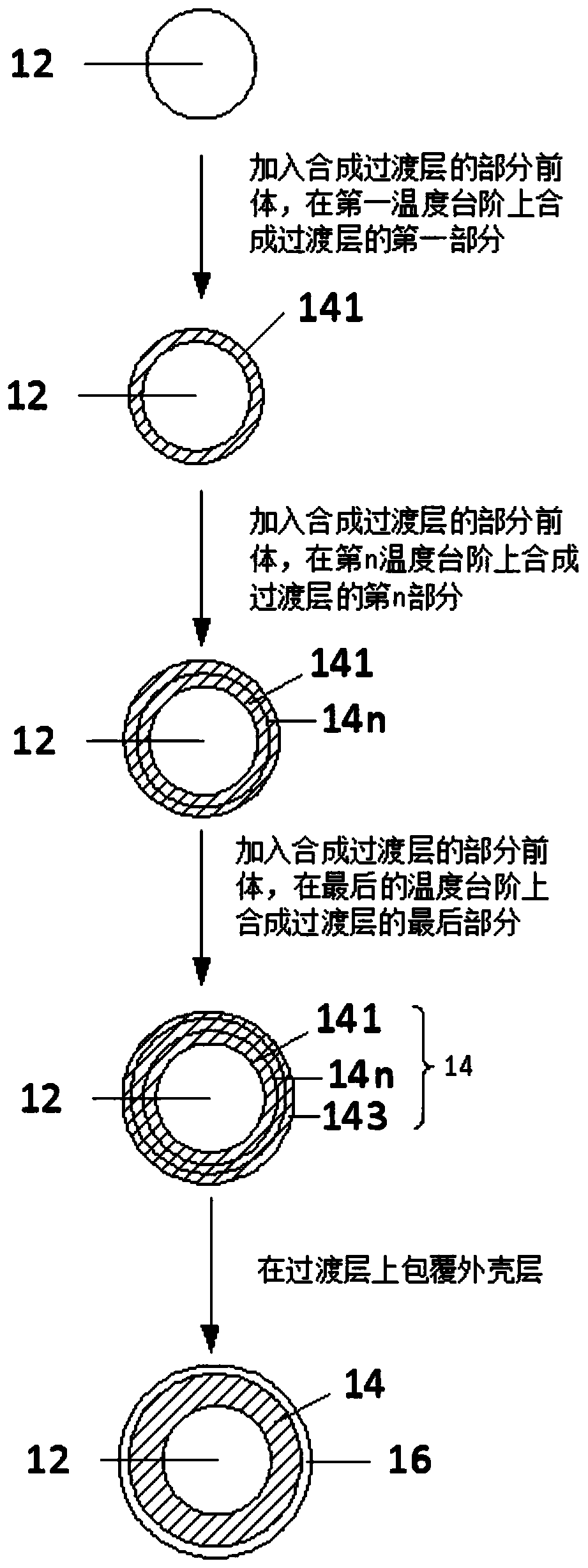

[0044] According to a preferred embodiment of the present application, the preparation method of the reaction system comprising the nanocrystal nucleus comprises steps:

[0045] The nano crystal nucleus is obtained, and the nano crystal nucleus is dispersed in an organic solvent to obtain a reaction system containing the nano crystal nucleus.

[0046] According to a preferred embodiment of the present application, the preparation method of the reaction system comprising the nanocrystal nucleus comprises steps:

[0047] Adding the precursors required for synthesizing nano crystal nuclei to the organic solvent, allowing the precursors required for synthesizing nano crystal nuclei to react in the organic solvent to generate nano crystal nuclei to obtain a reaction system containing nano crystal nuclei.

[0048] According to a preferred embodiment of the present application, the organic solvent includes at least one of C10-C22 alkanes, alkenes, halogenated hydrocarbons, aromatic h...

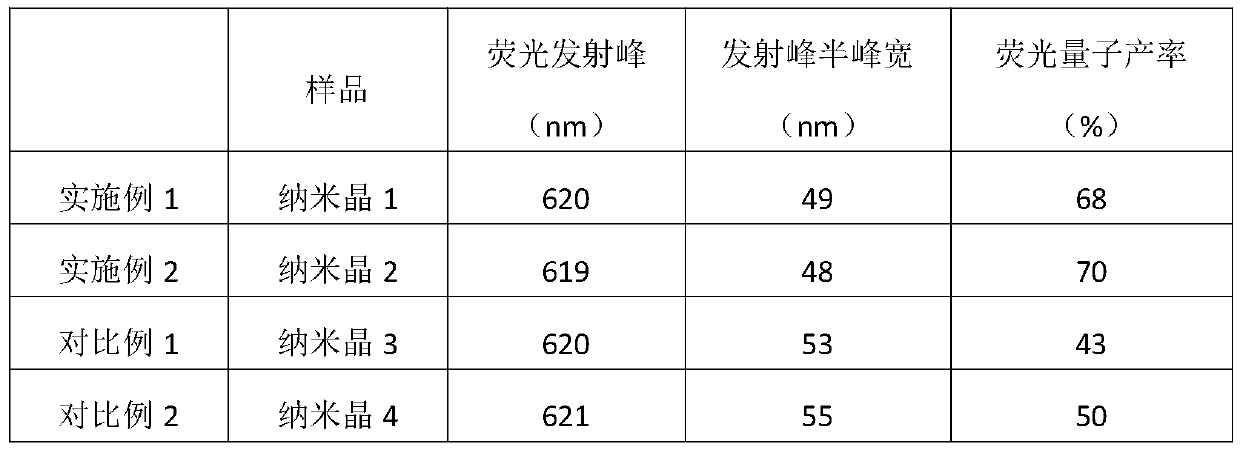

Embodiment 1

[0054] Preparation of core-shell structure nanocrystal 1:

[0055] Step 1-1, obtaining a reaction system containing InP nanocrystal nuclei: under an inert gas atmosphere, make 1mmol InCl 3 , 2mmolZnCl 2 , 20 mL of oleylamine, and 4 mmol of tris(diethylamino)phosphine were mixed, heated at 120°C for reaction, then at 190°C, a total of 5 mL of selenium-trioctylphosphine solution (2M) was added to the reaction system, and reacted for 30 minutes to obtain InP Nanocrystalline nucleus; in this step 1-1, the surface of InP nanocrystalline nucleus contains a very thin ZnSe layer, is to protect InP nanocrystalline nucleus, and this very thin ZnSe layer can be regarded as a part of InP nanocrystalline nucleus;

[0056] Step 1-2, preparation of the transition layer: Add 5 mmol of zinc stearate at one time to the reaction system at 190 °C in step 1-1, and add 20 mL of selenium trioctylphosphine solution (2M) in a gradient manner ;The method of adopting staged gradient temperature rise i...

Embodiment 2

[0059] Preparation of core-shell structure nanocrystal 2:

[0060] Step 2-1, obtaining a reaction system containing InP nanocrystal nuclei: under an inert gas atmosphere, make 1mmol InCl 3 , 2mmolZnCl 2 , 20 mL of oleylamine, and 4 mmol of tris(diethylamino)phosphine were mixed, heated and reacted at 120° C., and then at 180° C., a total of 3 mL of selenium trioctylphosphine solution (2M) was added to the reaction system, and reacted for 30 minutes to obtain InP nanocrystal nucleus: In the step 2-1, there will be a very thin ZnSe layer on the surface of the InP nanocrystal nucleus to protect the InP nanocrystal nucleus, and this very thin ZnSe layer can be regarded as a part of the InP nanocrystal nucleus;

[0061] Step 2-2, preparation of the transition layer: Add 10 mmol of zinc stearate at one time to the reaction system at 180° C. in step 2-1, and add 30 mL of selenium trioctylphosphine solution (2M) in a gradient manner ; At the same time, the temperature of the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com