Method and device for recycling protein wastewater

A protein wastewater and protein technology, applied in chemical instruments and methods, oil/oily substance/float removal devices, water/sewage treatment, etc., can solve the problems of waste of biological resources, low content of sericin, water pollution, etc. Achieve the effect of reducing the degree of membrane fouling, effectively removing salt, and operating safely and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

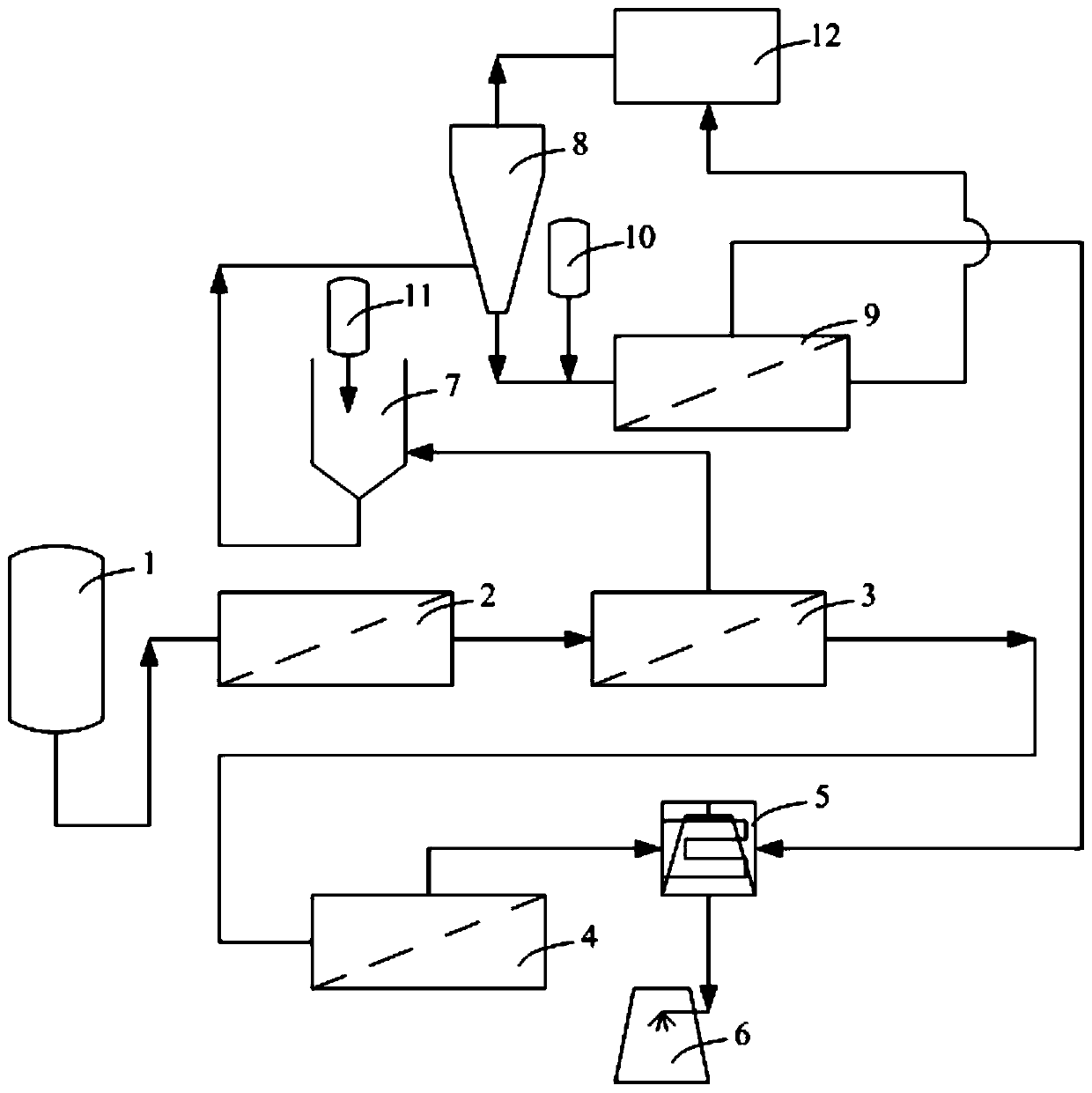

Method used

Image

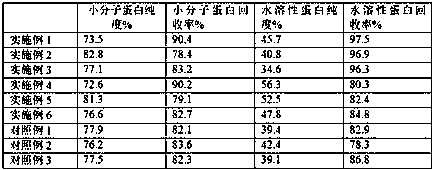

Examples

Embodiment 1

[0075] (1) The sericin wastewater in the silk refining process is clarified with a 1 μm hollow fiber membrane, filtered and then concentrated;

[0076] (2) Continue to filter the permeate obtained in step (1) with a 20nm ceramic membrane, concentrate it by 20 times, and add washing water 3 times the volume of the concentrated solution for cleaning.

[0077] (3) After the diafiltration is completed, the washing filtrate and permeate in step (2) pass through an organic membrane with a molecular weight cut-off of 5000Da, concentrate to a material concentration of 13%, and add 3 times the volume of the concentrated solution to wash and wash.

[0078] (4) Dry the concentrate in step (3) to obtain the highest value small molecule protein.

[0079] In step (2), the concentrated solution is dried to obtain soluble protein.

Embodiment 2

[0081] (1) Sericin wastewater from the silk refining process is clarified with a 0.5 μm ceramic membrane, filtered and then concentrated;

[0082] (2) Continue to filter the permeate obtained in step (1) with a 4nm ceramic membrane, concentrate it by 25 times, and add washing water whose volume is 1 times that of the concentrated solution for cleaning.

[0083] (3) After the diafiltration is completed, the washing filtrate and permeate in step (2) pass through an ultrafiltration membrane with a molecular weight cut-off of 50,000 Da, concentrate to a material concentration of 15%, and add 1 times the volume of the concentrated solution to wash and wash.

[0084] (4) Dry the concentrate in step (3) to obtain the highest value small molecule protein.

[0085] In step (2), the concentrated solution is dried to obtain soluble protein.

Embodiment 3

[0087] (1) The sericin wastewater in the silk refining process is clarified with a 0.5 μm organic microfiltration membrane, and then concentrated after filtration;

[0088] (2) Continue to filter the permeate obtained in step (1) with a 12nm ceramic membrane, concentrate it by 23 times, and add washing water twice the volume of the concentrated solution for cleaning.

[0089] (3) After the diafiltration is completed, the washing filtrate and permeate in step (2) pass through an organic membrane with a molecular weight cut-off of 20,000 Da, concentrate to a material concentration of 14%, and add 2 times the volume of the concentrated solution to wash and wash.

[0090] (4) Dry the concentrate in step (3) to obtain the highest value small molecule protein.

[0091] In step (2), the concentrated solution is dried to obtain soluble protein.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com