High-abrasion-resistance PU synthetic leather and preparation method thereof

A synthetic leather, high wear-resistant technology, used in textiles and papermaking, etc., can solve the problem of thermal temperature resistance, light stability, hydrolysis stability, weak air permeability and antibacterial properties, poor wear resistance of PU coating, and problems for users Health hazards and other issues, to improve the electromagnetic shielding performance, inhibit the growth of bacteria, and protect the health of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

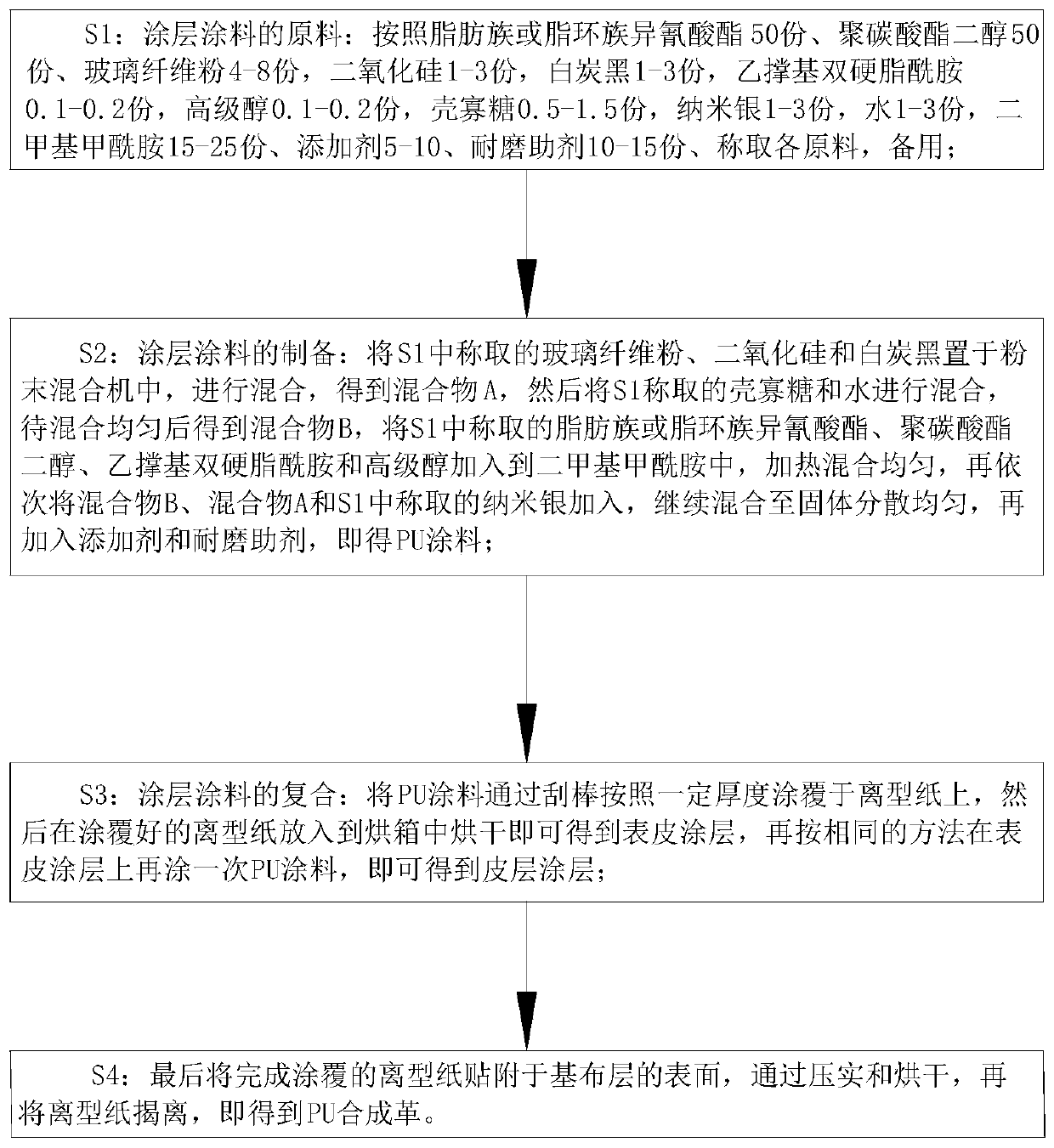

[0031] like Figure 1 to Figure 5 As shown, the preparation method of a kind of high wear-resistant PU synthetic leather of the present invention, this preparation method comprises the following steps:

[0032] S1: Raw materials of coating 2: according to 50 parts of aliphatic or alicyclic isocyanate, 50 parts of polycarbonate diol, 4-8 parts of glass fiber powder, 1-3 parts of silica, and 1-3 parts of silica parts, 0.1-0.2 parts of ethylene bis-stearamide, 0.1-0.2 parts of higher alcohol, 0.5-1.5 parts of chitosan oligosaccharide, 1-3 parts of nano silver, 1-3 parts of water, 15-25 parts of dimethylformamide parts, 5-10 parts of additives, 10-15 parts of wear-resistant additives, weigh each raw material and set aside; the PU coating prepared from the above-mentioned raw materials has excellent waterproofness, air permeability and antibacterial property compared with the traditional technical PU coating , It can be used in a humid environment for a long time, and it is not ea...

Embodiment approach

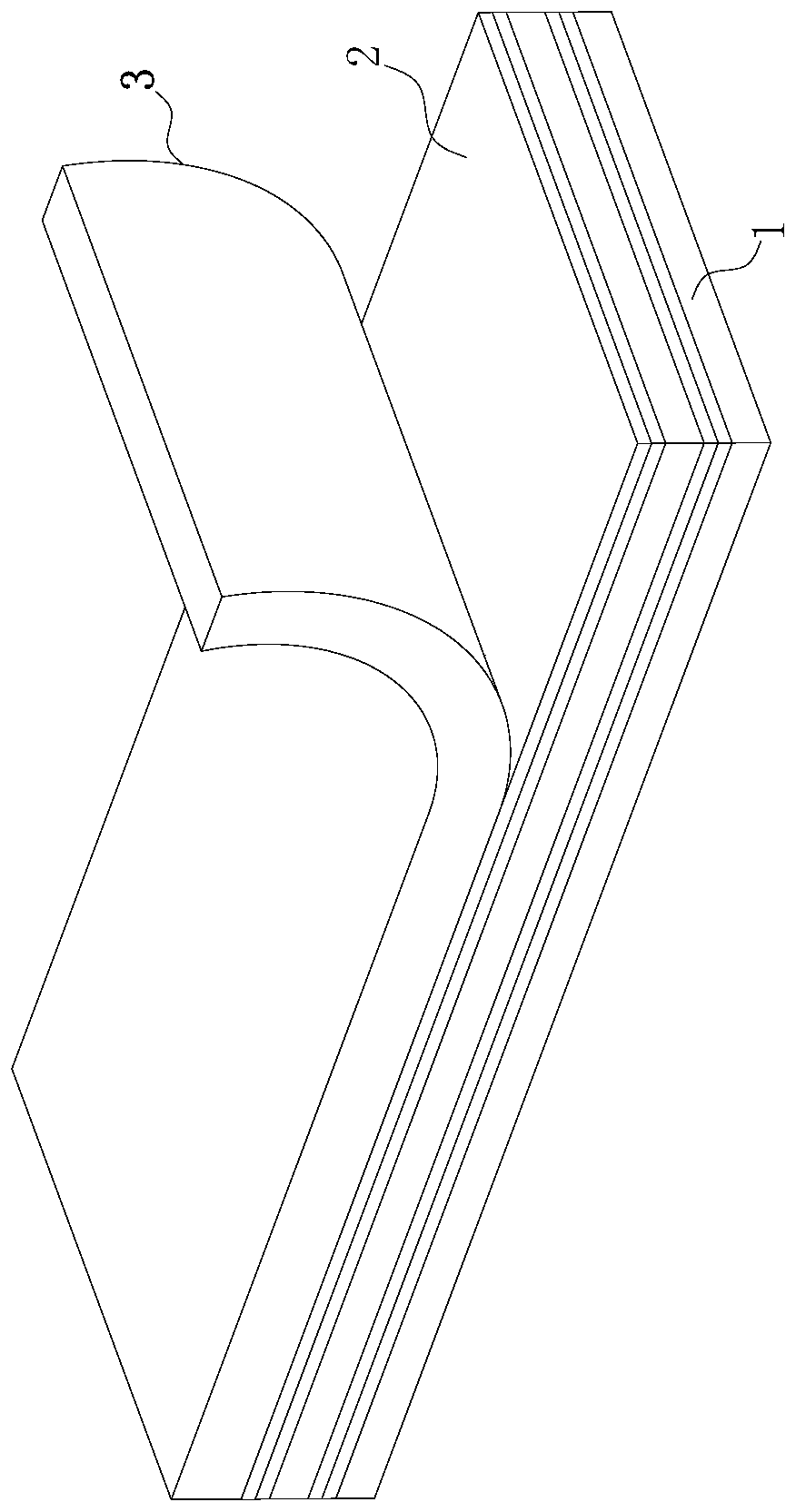

[0041]As an embodiment of the present invention, an adsorption layer 12 is attached to the lower surface of the fiber reinforced layer 11; the adsorption layer 12 is designed with activated carbon material; during operation, by setting the adsorption layer 12, harmful gases in the air can be adsorbed , to prevent the gas emitted from the synthetic leather from causing harm to the human body, and the inside of the adsorption layer 12 can emit negative ions, which is beneficial to human health.

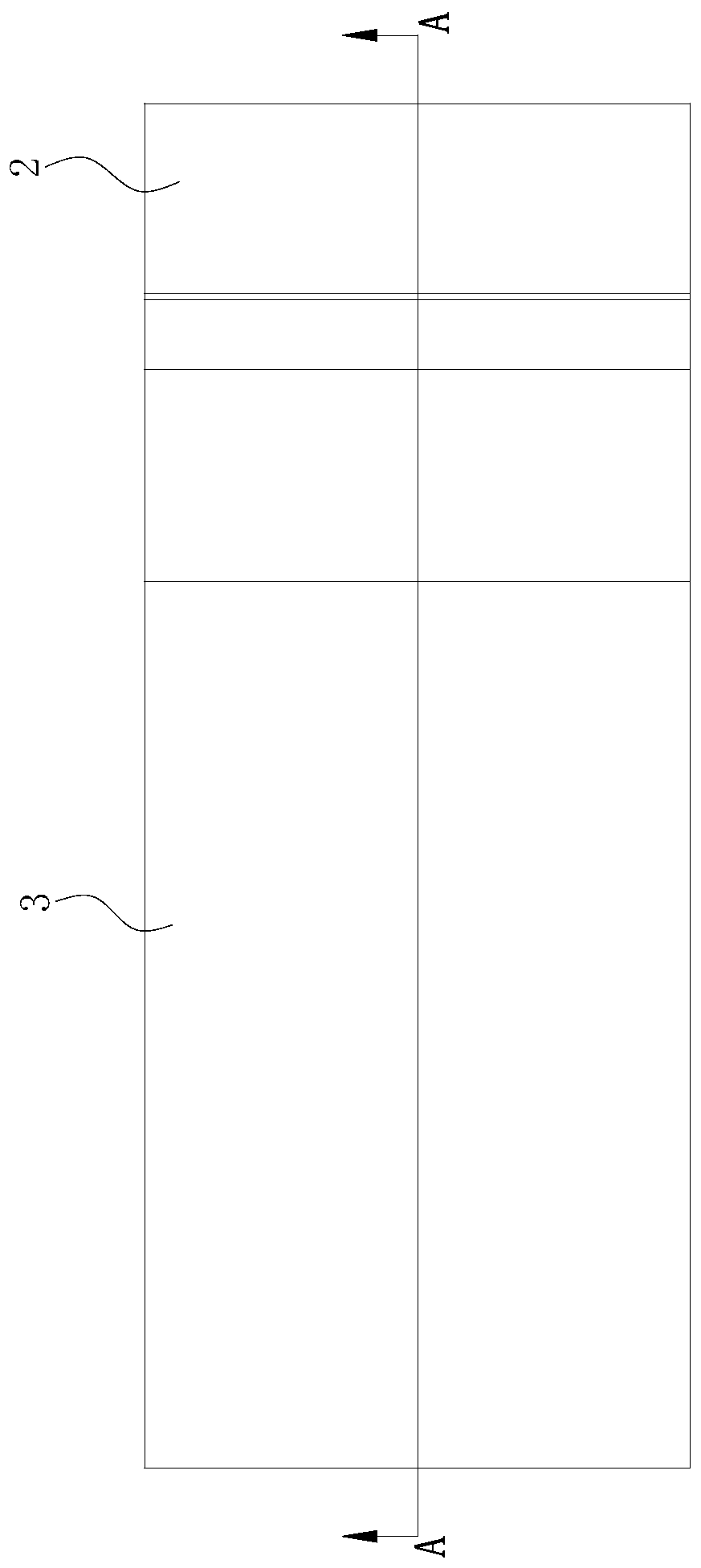

[0042] As an embodiment of the present invention, the double-layer composite non-woven fabric is provided with evenly arranged first guide holes 31 on one side of the release paper 3; the double-layer composite non-woven fabric is away from the release paper. 3. There are second guide holes 32 evenly arranged on one side; the number of the second guide holes 32 and the first guide holes 31 are equal, and the positions are set in one-to-one correspondence; Small lime particles 34; when w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com