Tail wine utilization method

A tail wine quality technology, applied in the field of wine making, can solve the problems of the loss of aroma substances in the tail wine, rough taste of the tail wine, poor economic benefits, etc., and achieve the effects of strong aroma, prolonging the storage time, and reducing the content of organic acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

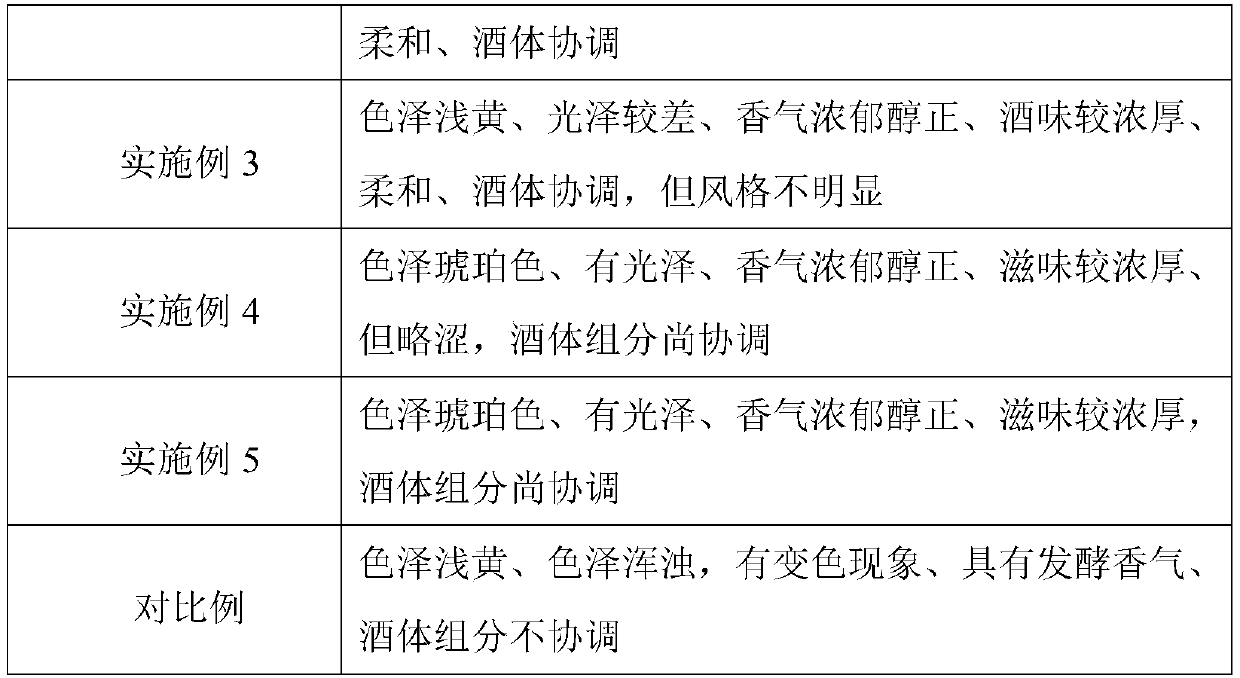

Embodiment 1

[0021] A method for utilizing tail wine, characterized in that it comprises the following steps:

[0022] S1. In parts by mass, 100 parts of tail wine, 10 parts of Shuanglun bottom grain, 10 parts of esterification liquid, 20 parts of mushroom powder, the mushroom powder includes 30 parts of Pleurotus eryngii, 5 parts of seafood mushroom, 20 parts of tea tree mushrooms and 15 parts of shiitake mushrooms, mixed evenly, placed in a fermenter for 7 days of fermentation, filtered to obtain a fermented liquid;

[0023] S2. Boil 5 parts of Zanthoxylum bungeanum pepper, 3 parts of kaempferen, 1 part of galangal, 5 parts of cinnamon, 1 part of cardamom, 3 parts of anise, 0.1 part of clove, and 100 parts of water for 20 minutes. After cooling and filtering, the material is obtained. liquid;

[0024] S3. Mix 50 parts of the fermented liquid obtained in step S1 with 20 parts of the feed liquid obtained in S2, add salt, 1 part of Luo Han fructose, and 3 parts of chitosan oligosaccharide ...

Embodiment 2

[0026] A method for utilizing tail wine, characterized in that it comprises the following steps:

[0027] S1. In parts by mass, 50 parts of tail wine, 30 parts of Shuanglun bottom grain, 5 parts of esterification liquid, 30 parts of mushroom powder, the mushroom powder includes 20 parts of Pleurotus eryngii, 10 parts of seafood mushroom, 10 parts of tea tree mushroom and 30 parts of shiitake mushroom, mixed evenly, placed in a fermenter for 5 days of fermentation, filtered to obtain a fermented liquid;

[0028] S2. Boil 7 parts of Zanthoxylum bungeanum, 1 part of kaempferen, 3 parts of galangal, 3 parts of cinnamon, 3 parts of cardamom, 1 part of anise, 0.5 parts of cloves, and 100 parts of water for 10 minutes. After cooling and filtering, the material is obtained. liquid;

[0029] S3. Mix 30 parts of the fermented liquid obtained in step S1 with 10 parts of the feed liquid obtained in S2, add salt, 3 parts of Luo Han fructose, and 1 part of chitosan oligosaccharide to prepa...

Embodiment 3

[0031] A method for utilizing tail wine, characterized in that it comprises the following steps:

[0032] S1. Mix 50 parts of tail wine, 30 parts of Shuanglun bottom grains, and 5 parts of esterification liquid in parts by mass, put them in a fermenter for fermentation for 5 days, and filter to obtain a fermented liquid;

[0033] S2. Boil 7 parts of Zanthoxylum bungeanum, 1 part of kaempferen, 3 parts of galangal, 3 parts of cinnamon, 3 parts of cardamom, 1 part of anise, 0.5 parts of cloves, and 100 parts of water for 10 minutes. After cooling and filtering, the material is obtained. liquid;

[0034] S3. Mix 50 parts of the fermented liquid obtained in step S1 with 10 parts of the feed liquid obtained in S2, add salt, 3 parts of Luo Han fructose, and 1 part of chitosan oligosaccharide to prepare, sterilize, fill the altar and seal it, and age to obtain seasoning wine .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com