Green and energy-saving method for treating VOCs gas of synthetic rubber drying unit and purification system

A technology of synthetic rubber and drying unit, which is applied in the field of green and energy-saving treatment of VOCs gas in synthetic rubber drying unit, which can solve the problems of high pressure drop, large air volume, and difficult exhaust gas compliance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

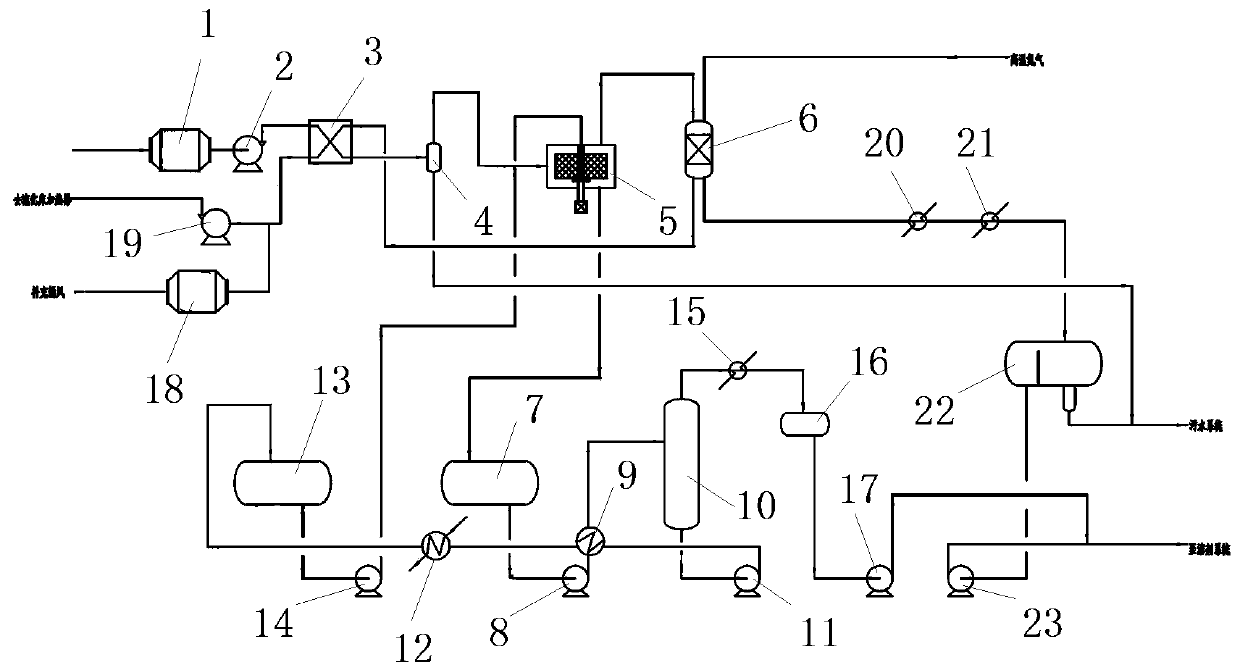

[0061] see figure 1 , The VOCs gas recovery treatment device of this embodiment includes 1-filter, 2-first fan, 3-first heat exchanger, 4-condensed water collection tank, 5-high gravity absorber, 6-adsorption assembly, 7 -rich absorption liquid tank, 8-rich absorption liquid production pump, 9-desorption tower inlet and outlet heat exchanger, 10-desorption tower, 11-desorption tower tank extraction pump, 12-desorption tower tank discharge cooler , 13-lean absorption liquid buffer tank, 14-lean absorption liquid extraction pump, 15-recovery solvent condenser, 16-solvent recovery tank, 17-recovery solvent extraction pump, 18-fresh air filter, 19-second fan , 20-the first desorption cooler, 21-the second desorption co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com