Tungsten carbide/cadmium zinc sulfide composite photocatalyst as well as preparation method and application thereof

A technology of tungsten carbide and cadmium sulfide, applied in the field of photocatalytic materials, can solve the problems of low carrier space separation efficiency and high hydrogen production overpotential, and achieve excellent photocatalytic hydrogen production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] This embodiment proposes a preparation method of tungsten carbide / cadmium zinc sulfide composite photocatalyst, comprising the following steps:

[0031] S1, dispersing tungsten carbide in water to obtain a suspension;

[0032] S2. Add soluble cadmium salt and soluble zinc salt to the suspension according to the molar mass ratio of cadmium to zinc of 1:10 to 10:1, and then add the concentration to 0.0001mol L -1 ~10mol·L -1 Sodium hydroxide and / or a concentration of 0.0001mol L -1 ~10mol·L -1 Potassium hydroxide adjusts the pH value to 4-10, and stirs evenly; the soluble cadmium salt is cadmium acetate; and / or, the soluble zinc salt is zinc acetate;

[0033] S3, according to the total molar mass ratio of the cadmium in the soluble cadmium salt and the zinc of the soluble zinc salt to the molar mass ratio of sulfur in the sodium sulfide solution and / or potassium sulfide solution 1:1-2, according to the obtained W in the tungsten carbide / cadmium zinc sulfide composite ...

Embodiment 1

[0038] A preparation method of tungsten carbide / cadmium zinc sulfide composite photocatalyst, comprising the following steps:

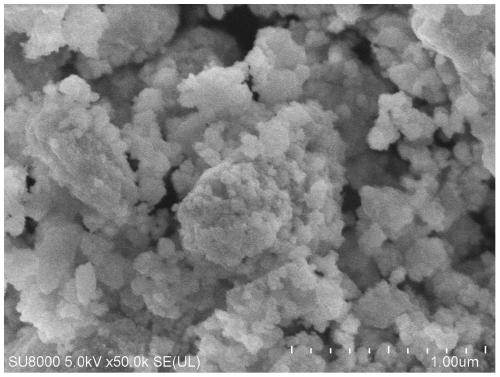

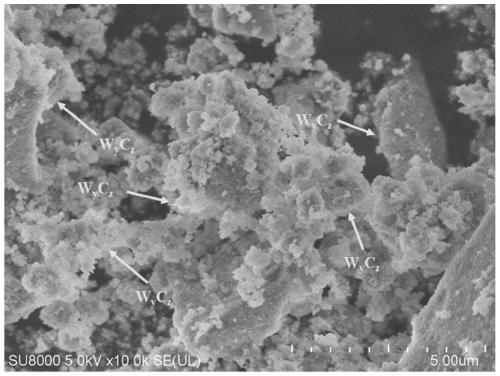

[0039] S1. Weigh 7.250 mg of tungsten carbide and ultrasonically disperse it in 100 mL of deionized water to obtain a suspension of tungsten carbide;

[0040] S2, the cadmium acetate of 0.7996g and the zinc acetate of 0.6585g are added in the suspension, after stirring evenly, the gained suspension is mixed with NaOH solution (0.2mol L -1 ) to adjust the pH to 7; stir for half an hour until uniform;

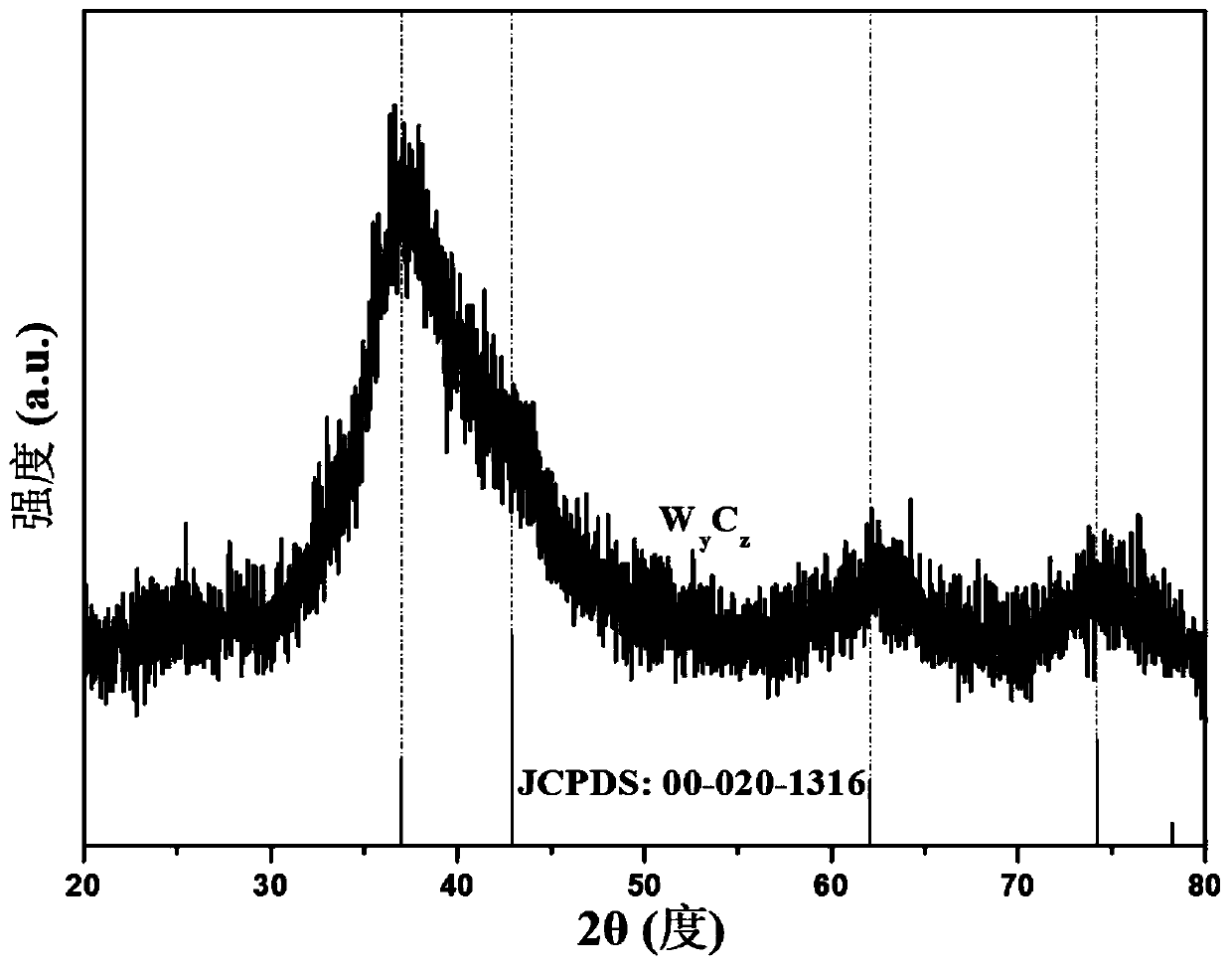

[0041] S3, add 12mLNa dropwise 2 S solution (0.5mol·L -1 ), after stirring at 30°C for 18h, the resulting precipitate was collected, washed with absolute ethanol and deionized water several times and then dried to obtain W y C z W content is 1wt% y C z / Zn x Cd 1-x S composite photocatalyst.

Embodiment 2

[0043] A preparation method of tungsten carbide / cadmium zinc sulfide composite photocatalyst, comprising the following steps:

[0044] S1. Weigh 14.5 mg of tungsten carbide and ultrasonically disperse it in 100 mL of deionized water to obtain a suspension of tungsten carbide;

[0045] S2, the cadmium acetate of 0.7996g and the zinc acetate of 0.6585g are added in the suspension, after stirring evenly, the gained suspension is mixed with NaOH solution (0.2mol L -1 ) to adjust the pH to 7. Stir for half an hour until uniform;

[0046] S3, add 12mLNa dropwise 2 S solution (0.5mol·L -1 ). After stirring at 30 °C for 18 h, the resulting precipitate was collected, washed with absolute ethanol and deionized water several times, and dried to obtain W y C z W content is 2wt% y C z / Zn xC d 1-x S composite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com