Surface acoustic wave-based shape memory composite member controllable deformation three-dimensional printing method

A surface acoustic wave and composite component technology, which is applied in the auxiliary operation of additional layers, 3D object support structure, additive manufacturing, etc., can solve problems such as accurate programming of difficult structural changes, difficult control of structural deformation, narrow application range, etc., to achieve high The effect of flexibility, simple manufacturing process and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

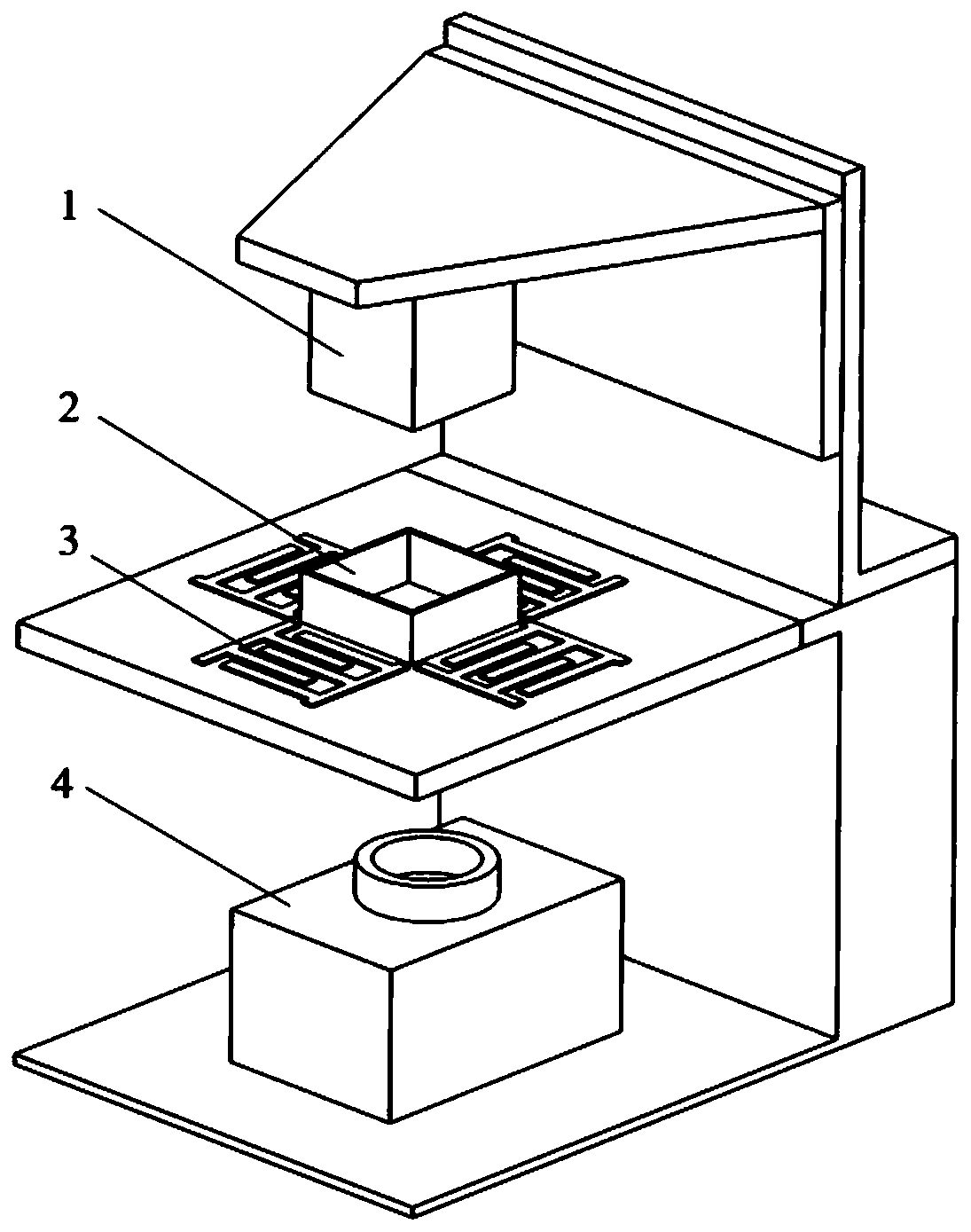

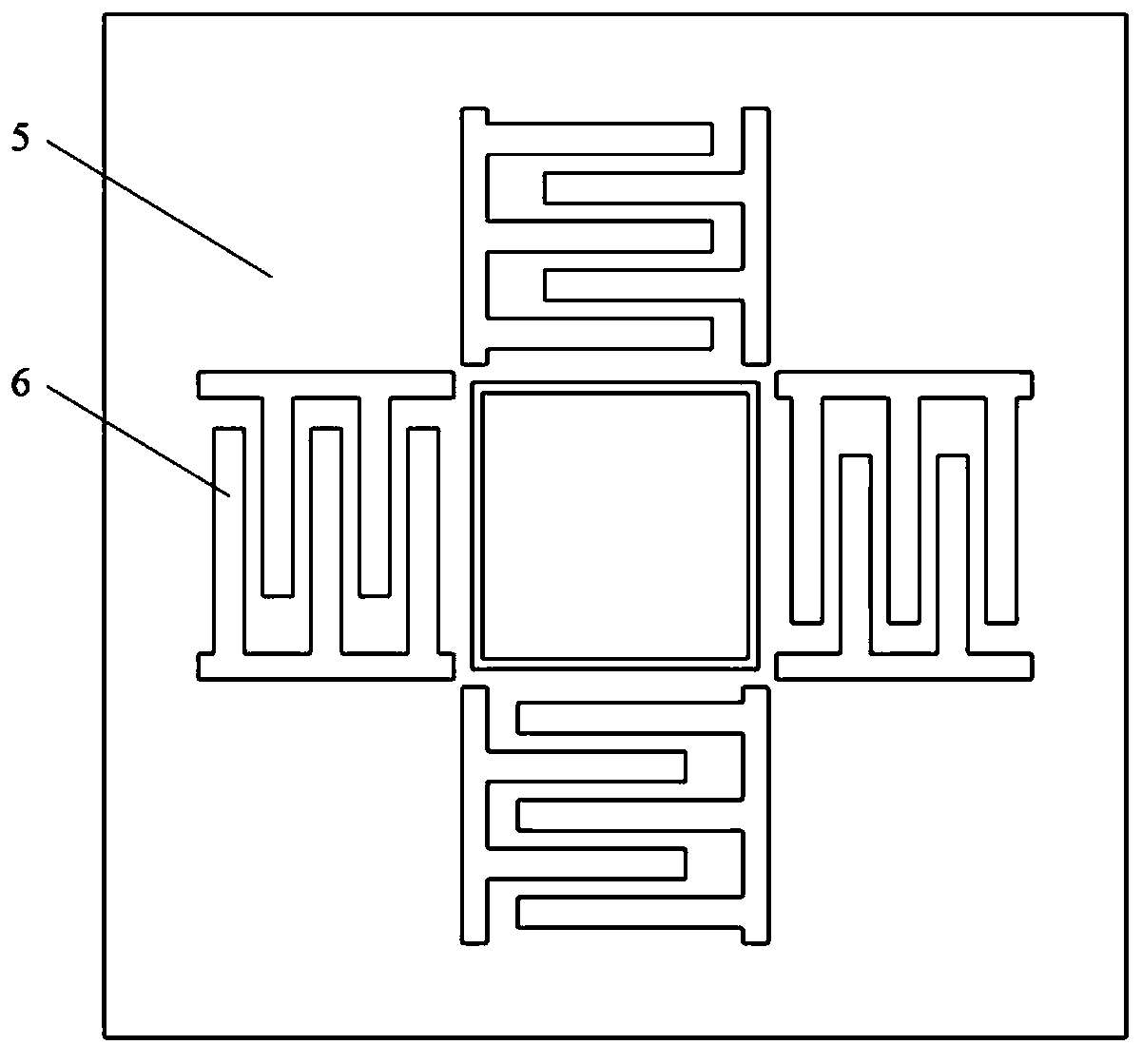

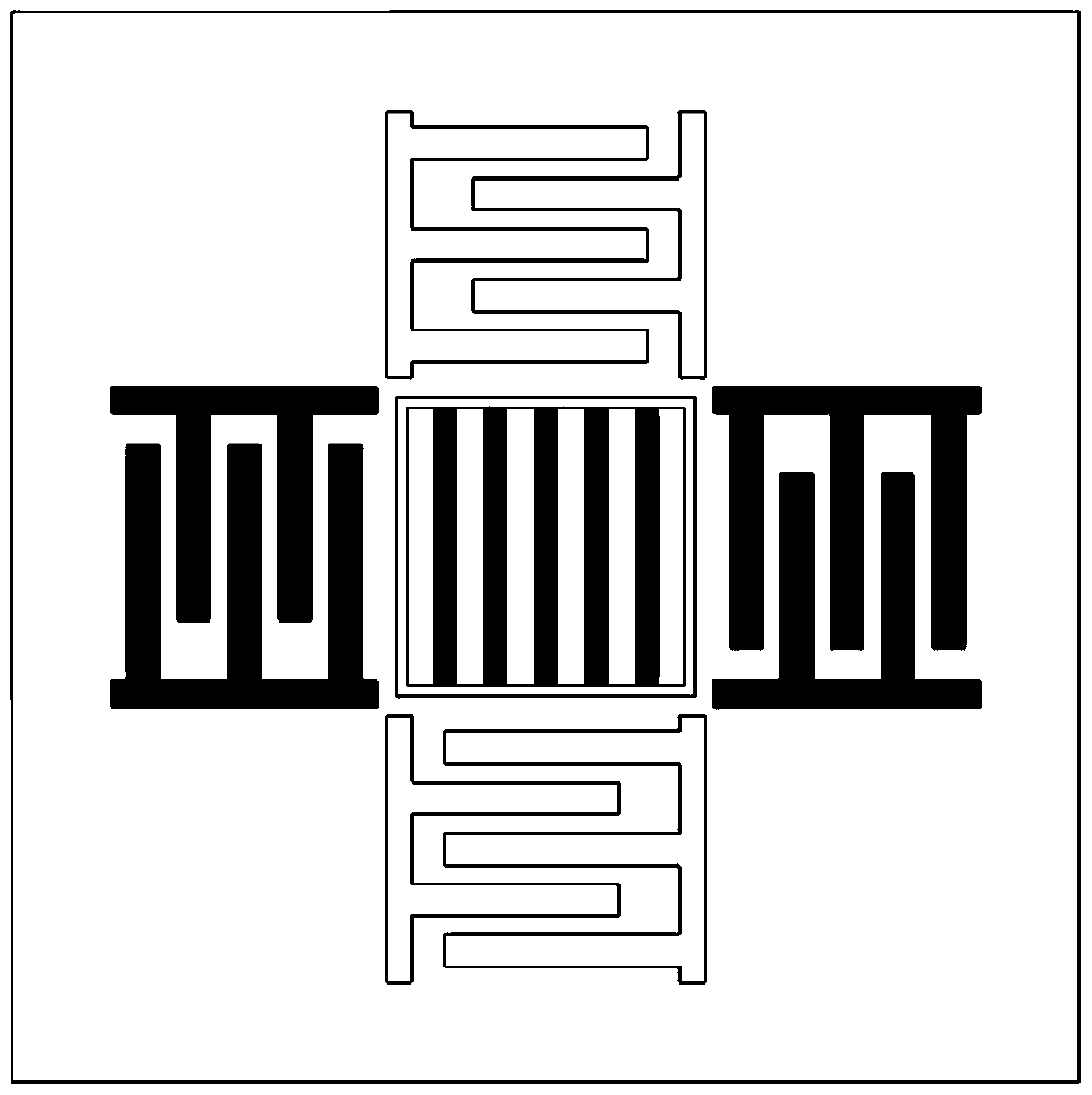

[0047] Such as figure 1 As shown, the device is placed on an optical vibration isolation platform, and the device includes an electric z-axis translation stage 1 placed on the optical vibration isolation platform, a printing liquid tank 2, two pairs of surface acoustic wave transducers 3 and a UV curing lamp. Light projection system 4; two pairs of surface acoustic wave transducers 3 are distributed around the printing liquid tank 2 on the colorless and transparent piezoelectric wafer 5, and two pairs of surface acoustic wave transducers 3 are located around the square printing liquid tank 2 Arranged vertically and orthogonally to each other, the photosensitive prepolymer and silver nanoparticles are placed in the printing liquid tank 2 in the center of the colorless and transparent piezoelectric chip, and the surface acoustic wave transducer 3 emits ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com