A method and device for preparing sodium acetate from acetic acid wastewater

A technology of sodium acetate and waste water, applied in the directions of carboxylate preparation, carboxylate preparation, separation method, etc., can solve problems such as the need to purchase acetic acid raw materials, and achieve the effects of being beneficial to comprehensive utilization, reducing steam consumption, and reducing heating burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

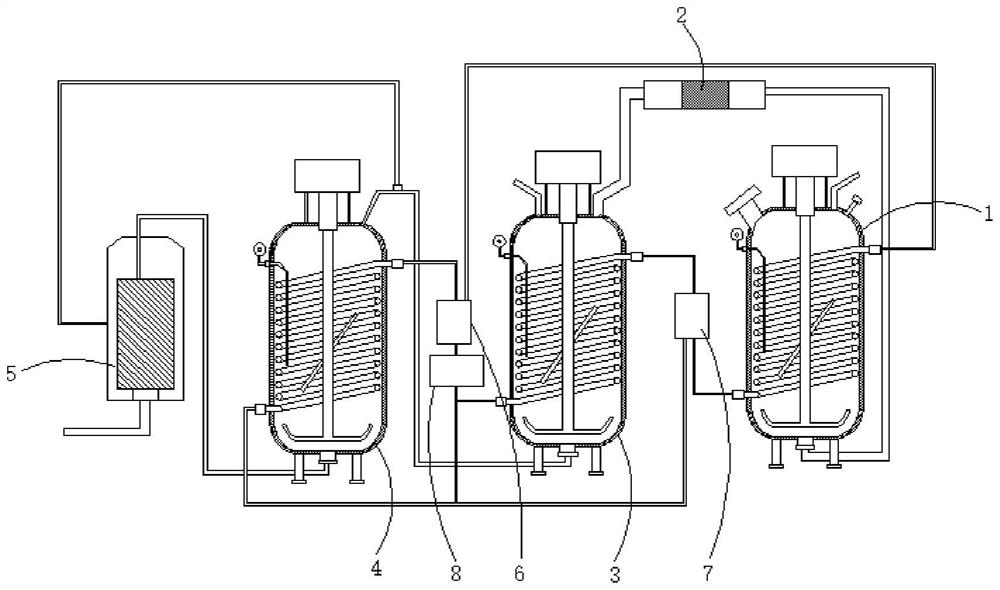

[0051] refer to image 3 , an energy-saving preparation system for preparing sodium acetate, comprising a bag filter, a neutralization reactor 1, a filter 2, a concentration reactor 3, a crystallization tank 4 and a separator 5 connected in sequence, and the communication pipelines between the above components are all set The delivery pump, that is, the acetic acid wastewater enters the neutralization reactor 1 after being filtered by the cloth bag filter, and caustic soda is added dropwise in the neutralization reactor 1 to enter the neutralization reaction, and the reacted reaction liquid passes through the filter 2 to filter impurities and then enters the concentration reactor In 3, the concentrated mother liquor after concentration enters crystallization tank 4 to carry out crystallization, and the mixed solution after crystallization completes enters separator 5, and separator 5 separates crystal and mother liquor, and the liquid outlet of pump described separator 5 and cr...

Embodiment 2

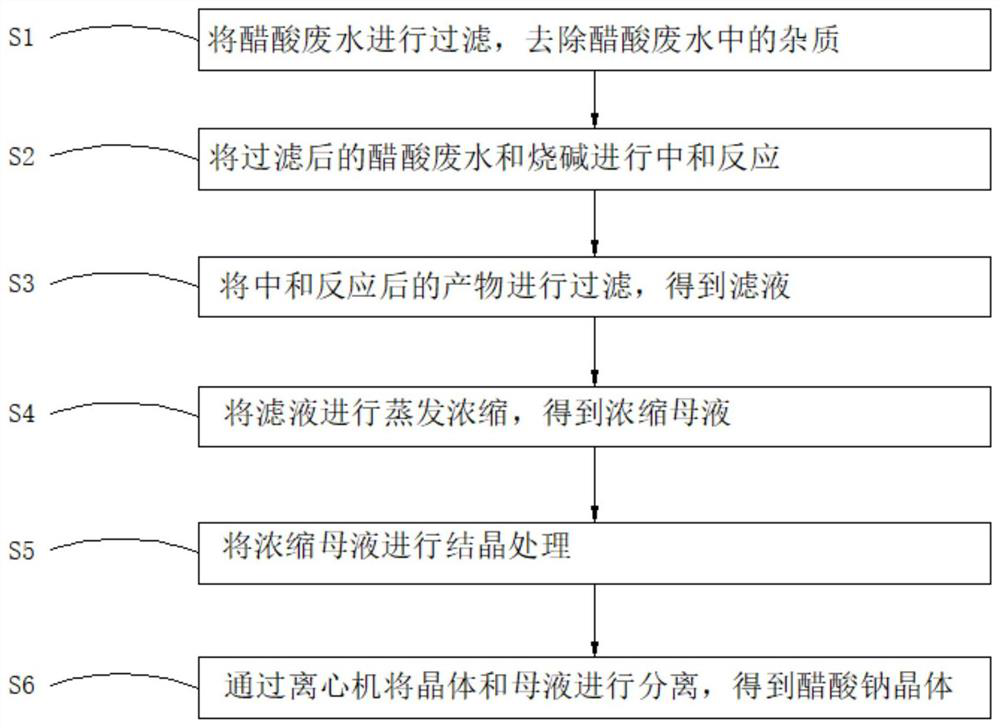

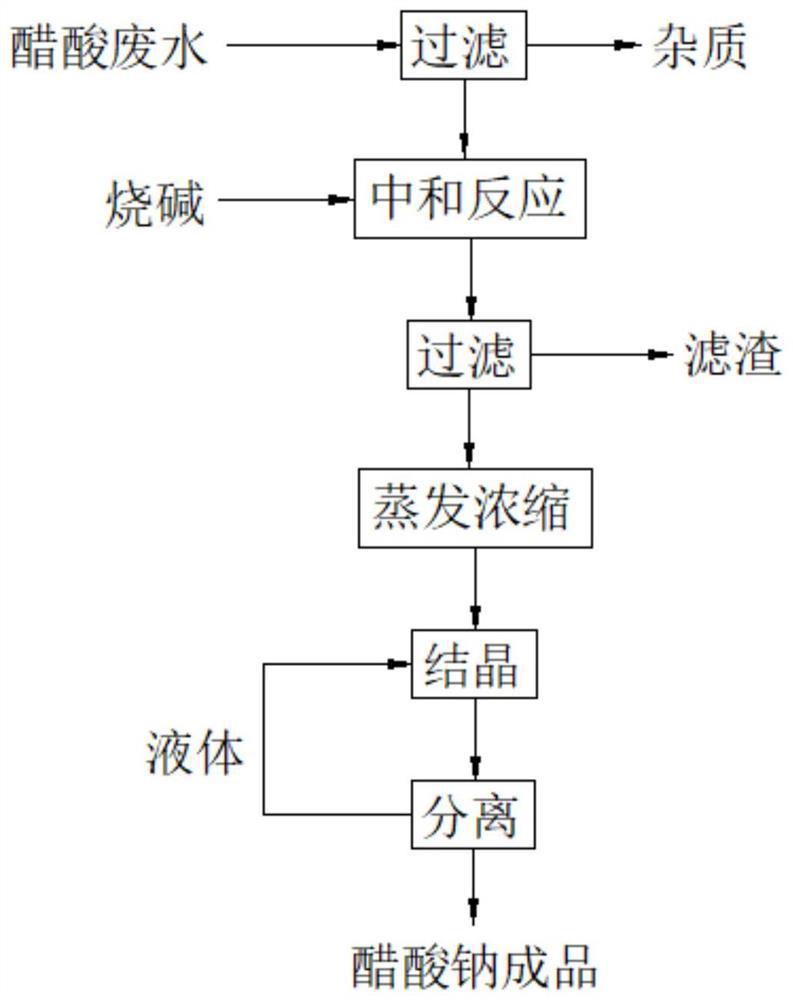

[0070] refer to figure 1 with figure 2, a preparation method of sodium acetate, is characterized in that, comprises the following steps:

[0071] S1: Filter the acetic acid wastewater to remove impurities in the acetic acid wastewater, and use a cloth bag filter as the filter;

[0072] S2: neutralize the filtered acetic acid wastewater and caustic soda, measure the content of acetic acid in the acetic acid wastewater, determine the quality of caustic soda, and control the temperature of the neutralization reaction at 60°C. The specific process is that caustic soda is slowly added dropwise to the acetic acid wastewater, which can fully react the relatively high-cost caustic soda, and at the same time avoid the occurrence of side reactions caused by excessive caustic soda; after the dropwise addition, keep the acetic acid wastewater The mass of acetic acid is 5% more than that of caustic soda.

[0073] S3: when the pH value of the reaction liquid of the neutralization reacti...

Embodiment 3

[0079] refer to figure 1 with figure 2 , a preparation method of sodium acetate, is characterized in that, comprises the following steps:

[0080] S1: Filter the acetic acid wastewater to remove impurities in the acetic acid wastewater, and use a cloth bag filter as the filter;

[0081] S2: neutralize the filtered acetic acid wastewater and caustic soda, measure the content of acetic acid in the acetic acid wastewater, determine the quality of caustic soda, and control the temperature of the neutralization reaction at 52°C. The specific process is that caustic soda is slowly added dropwise to the acetic acid wastewater, which can fully react the relatively high-cost caustic soda, and at the same time avoid the occurrence of side reactions caused by excessive caustic soda; after the dropwise addition, keep the acetic acid wastewater The mass of acetic acid is 6% more than that of caustic soda.

[0082] S3: when the pH value of the reaction liquid of the neutralization react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com