Antibacterial laundry detergent and preparation method thereof

A technology of laundry detergent and silver ion solution, applied in the field of laundry detergent, can solve the problems of inability to inhibit bacteria, single function of laundry detergent, etc., and achieve the effects of good lethality, strong decontamination ability and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

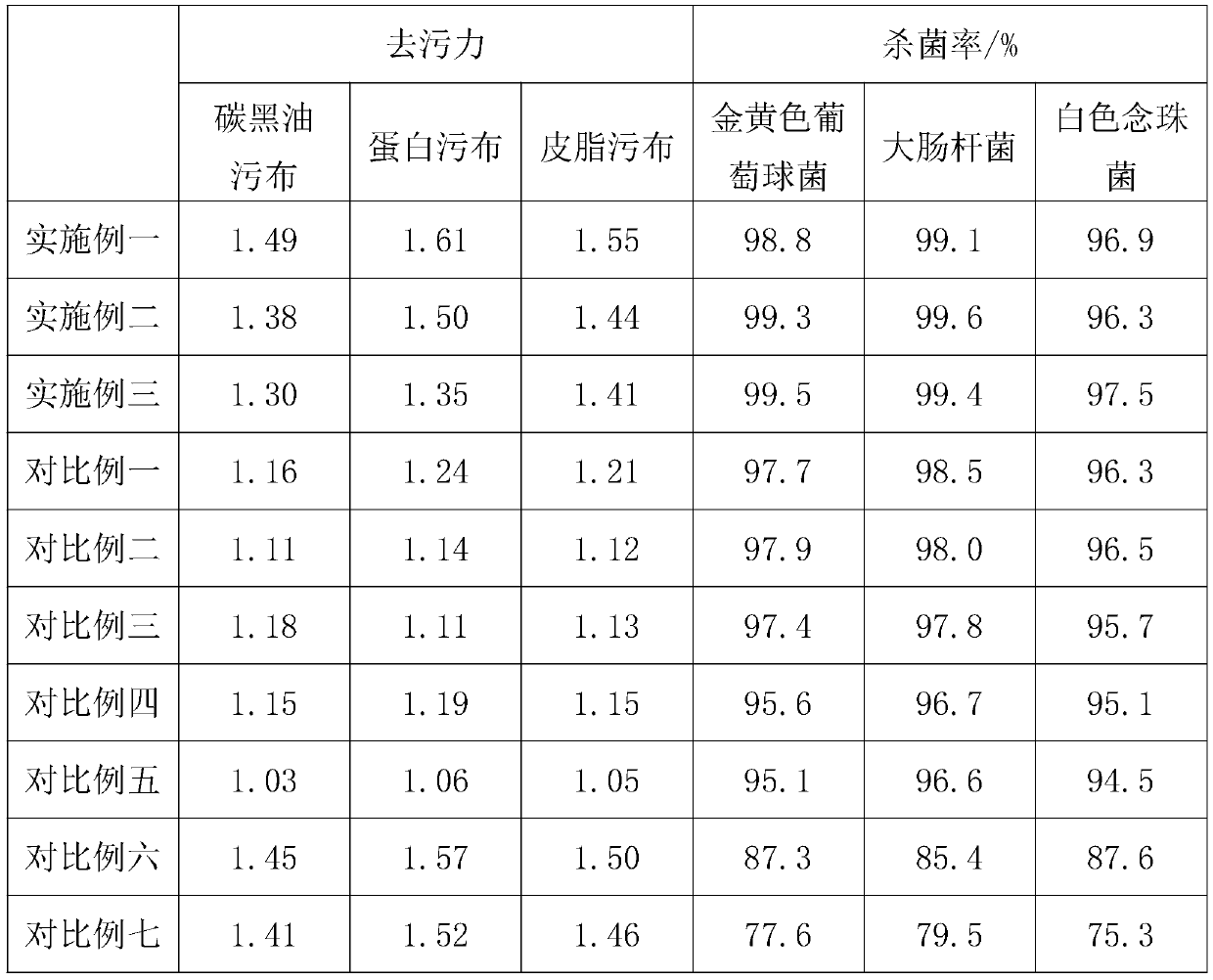

Examples

Embodiment 1

[0034] A kind of antibacterial laundry detergent, comprises the component of following mass percentage:

[0035] Sodium lauryl alcohol polyoxyethylene ether sulfate 10%, disodium edetate 0.1%, fatty alcohol polyoxyethylene ether AEO-98%, fatty acid potassium soap 3%, coconut oleic acid diethanolamide 6%, Cocamidopropyl Hydroxysultaine 5%, Nonionic Surfactant Isomeric Alcohol XP-89 1.2%, Sodium Polyacrylate 1.5%, Silver Nitrate Solution 0.3%, Borneo Camphor Oil 1.2%, Methyl Chlorisothiazole 0.05% ketone, 0.3% essence, and deionized water as the balance.

[0036] The coconut oleic acid diethanolamide is a reaction product of coconut oil fatty acid and diethanolamide in a molar ratio of 1:2. The fatty acid potassium soap is potassium laurate and potassium myristate, and the weight ratio of the two is 1:1. The silver ion concentration in the silver nitrate solution is 1500ppm.

[0037] A preparation method of antibacterial laundry detergent, comprising the following steps:

[...

Embodiment 2

[0042] A kind of antibacterial laundry detergent, comprises the component of following mass percentage:

[0043] Sodium lauryl alcohol polyoxyethylene ether sulfate 15%, disodium edetate 0.2%, fatty alcohol polyoxyethylene ether AEO-96%, fatty acid potassium soap 2%, coconut oleic acid diethanolamide 4%, Cocamidopropyl Hydroxysultaine 4%, Nonionic Surfactant Isomerized Alcohol XP-89 2.5%, Sodium Polyacrylate 2%, Silver Nitrate Solution 0.6%, Borneocamphor Oil 0.5%, Methylisothiazoline 0.1% ketone, 0.5% essence, and the balance is deionized water.

[0044] The coconut oleic acid diethanolamide is a reaction product of coconut oil fatty acid and diethanolamide in a molar ratio of 1:2. The fatty acid potassium soap is potassium laurate and potassium myristate, and the weight ratio of the two is 1:2. The silver ion concentration in the silver nitrate solution is 2000ppm.

[0045] A preparation method of antibacterial laundry detergent, comprising the following steps:

[0046] ...

Embodiment 3

[0050] A kind of antibacterial laundry detergent, comprises the component of following mass percentage:

[0051] Sodium lauryl alcohol polyoxyethylene ether sulfate 20%, disodium edetate 0.3%, fatty alcohol polyoxyethylene ether AEO-94%, fatty acid potassium soap 1%, coconut oleic acid diethanolamide 2%, Cocamidopropyl Hydroxysultaine 3%, Nonionic Surfactant Isomerized Alcohol XP-89 1.8%, Sodium Polyacrylate 2.5%, Silver Nitrate Solution 0.5%, Borneo Camphor Oil 2%, Methyl Chlorisothiazole 0.2% ketone, 0.4% essence, and the balance is deionized water.

[0052] The coconut oleic acid diethanolamide is a reaction product of coconut oil fatty acid and diethanolamide in a molar ratio of 1:2. The fatty acid potassium soap is potassium laurate and potassium myristate, and the weight ratio of the two is 1:2. The silver ion concentration in the silver nitrate solution is 2500ppm.

[0053] A preparation method of antibacterial laundry detergent, comprising the following steps:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com