Magnesium alloy and preparing method and application thereof

A magnesium alloy and pure magnesium technology, applied in the field of magnesium-air batteries, can solve the problems of not reaching the ideal state, hysteresis effect, limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

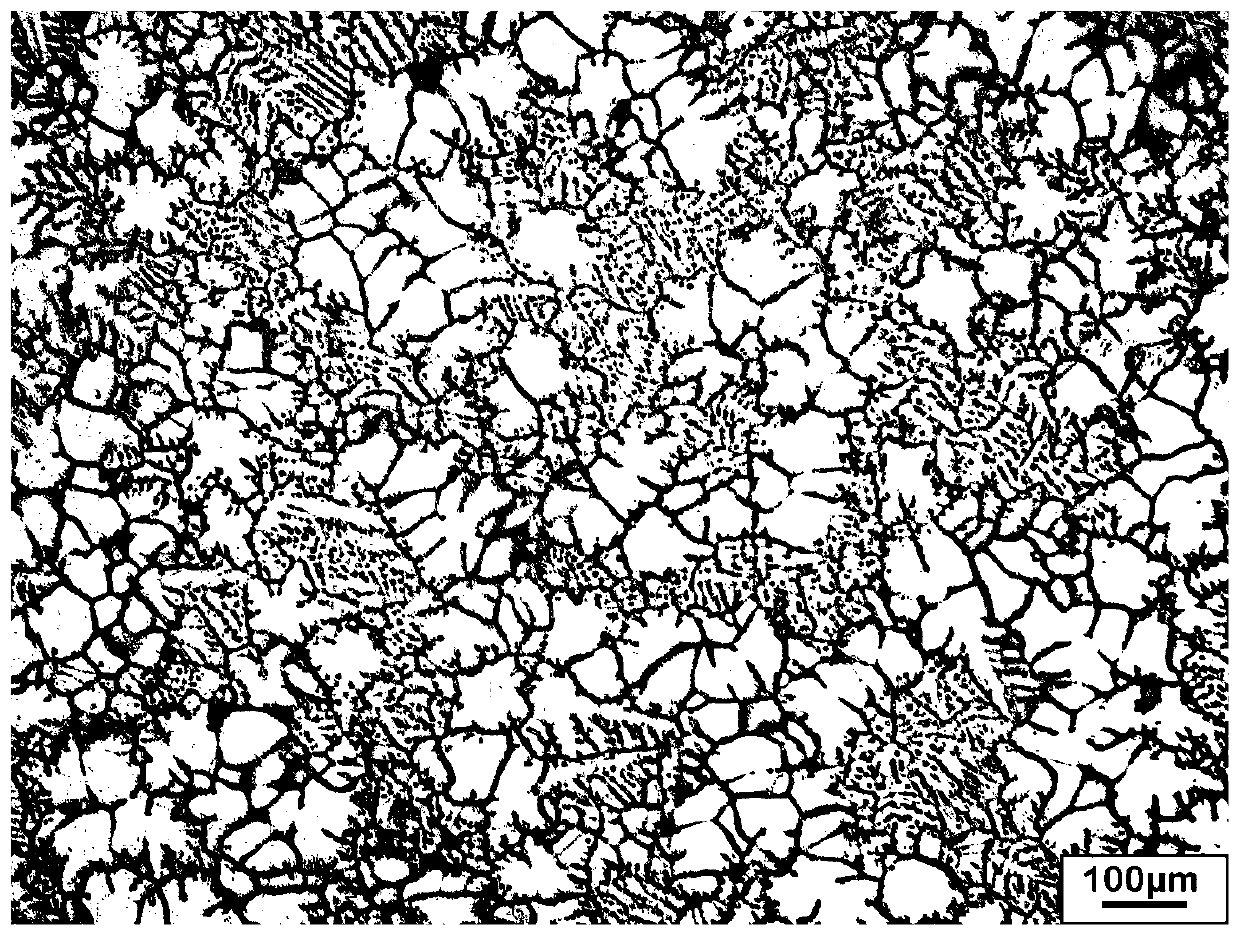

Image

Examples

preparation example Construction

[0023] The present invention provides a method for preparing the magnesium alloy described in the above technical solution, which includes the following steps:

[0024] Melting pure magnesium to obtain a magnesium melt;

[0025] According to the composition ratio of the anode material of the magnesium-air battery, the magnesium melt is mixed with tin particles and indium particles, cast, and cooled to obtain a magnesium alloy.

[0026] In the present invention, unless otherwise specified, all required preparation materials are commercially available products well known to those skilled in the art.

[0027] In the present invention, pure magnesium is smelted to obtain a magnesium melt. In the present invention, the purity of the pure magnesium is preferably ≥99.99%, and the pure magnesium is preferably industrial pure magnesium. Before weighing the pure magnesium according to the composition of the magnesium alloy, the present invention preferably sands off the oxide film on the surfa...

Embodiment 1

[0037] The composition ratio of magnesium alloy is Mg-0.5wt.%Sn-1.5wt.%In;

[0038] Preparation:

[0039] Preparation: Grind industrial pure magnesium (Mg purity ≥99.99%) with sandpaper, use an electronic balance to weigh and calculate the industrial pure magnesium, pure tin particles (Sn≥99.8%) and pure tin required to prepare Mg-Sn-In alloy The quality of indium particles (In≥99.99%).

[0040] The surface of the crucible is cleaned, and the surface of the crucible, crucible tongs, slag removal tool and right-angle stainless steel mold is repeatedly and evenly painted with paint (the quality of each component in the paint is 300g talc powder, 100g water glass and 1000g deionized water. ).

[0041] Melting and casting: The PDM-1 magnesium alloy melting furnace is heated from room temperature for the first time (heating rate is 6°C / min) to 650°C, and the crucible containing the magnesium block (161.72g) is clamped into the magnesium with crucible tongs The alloy melting furnace is fi...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is only that the composition ratio of the magnesium alloy is Mg-1wt.%Sn-2wt.%In, the raw material used is 143.886g pure magnesium blocks, 3.076g indium particles, and 1.495g tin particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com