Ultra-thin electronic glass fiber cloth surface treatment fluid and preparation method thereof

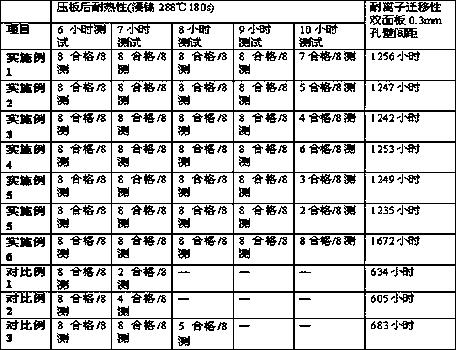

A technology of electronic glass fiber cloth and surface treatment liquid, which is applied in fiber processing, textile material processing, liquid/gas/vapor textile processing, etc. The cloth is prone to problems such as bubble delamination and adverse effects on the performance of copper clad laminates, to achieve the effect of improving heat resistance and ion migration resistance, improving heat resistance and ion migration resistance, and maintaining mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiments 1 to 5 are specific examples of an ultra-thin electronic glass fiber cloth surface treatment liquid and a preparation method thereof of the present invention, wherein embodiment 1 is the best implementation mode.

[0031] Y-Aminopropyltrimethoxysilane, CAS: 13822-56-5, Zouping Mingxing Chemical Co., Ltd., content ≥99%;

[0032] N-(2-aminoethyl)-3-aminopropyltrimethoxysilane, CAS: 1760-24-3, Zibo Linzi Qiquan Industry and Trade Co., Ltd., content ≥99%;

[0033] 3-(2,3-Glycidyloxypropoxy)propyltrimethoxysilane, CAS: 2530-83-8, Zibo Linzi Qiquan Industry and Trade Co., Ltd., content ≥99%;

[0034] Acetic acid, Yantai Sunkang Biotechnology Co., Ltd., content ≥ 99.5%;

[0035] Citric acid, Yantai Sunkang Biotechnology Co., Ltd., content ≥99.5%;

[0036] Defoamer, Zhuhai Zhanyang Chemical Co., Ltd., defoamer SS-013A.

[0037] Example 1

[0038] The present embodiment comprises the following raw materials by weight: 98 parts of water, surface treatment agent [Y...

Embodiment 2

[0043] The present embodiment comprises the following raw materials by weight: 98 parts of water, surface treatment agent [Y-aminopropyltrimethoxysilane and N-(2-aminoethyl)-3-aminopropyltrimethoxysilane by weight 1:1 mixing] 1.2 parts, 0.5 parts of acetic acid, 0.008 parts of defoamer;

Embodiment

[0044] The preparation method of embodiment, comprises the following steps:

[0045] 1) Control the water temperature to 30°C, add the surface treatment agent and defoamer to the water in parts by weight, and stir evenly to obtain a mixed solution;

[0046] 2) Add a weak acid to the mixed solution in parts by weight to obtain the surface treatment solution for ultra-thin electronic glass fiber cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com