Microwave preparation method of fuel cell dual-component alloy catalyst

A technology of alloy catalyst and fuel cell, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of difficult industrial scale-up, difficult control of particle size, and many preparation steps, and achieve simple equipment, element ratio and particle size Controllable, short-cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

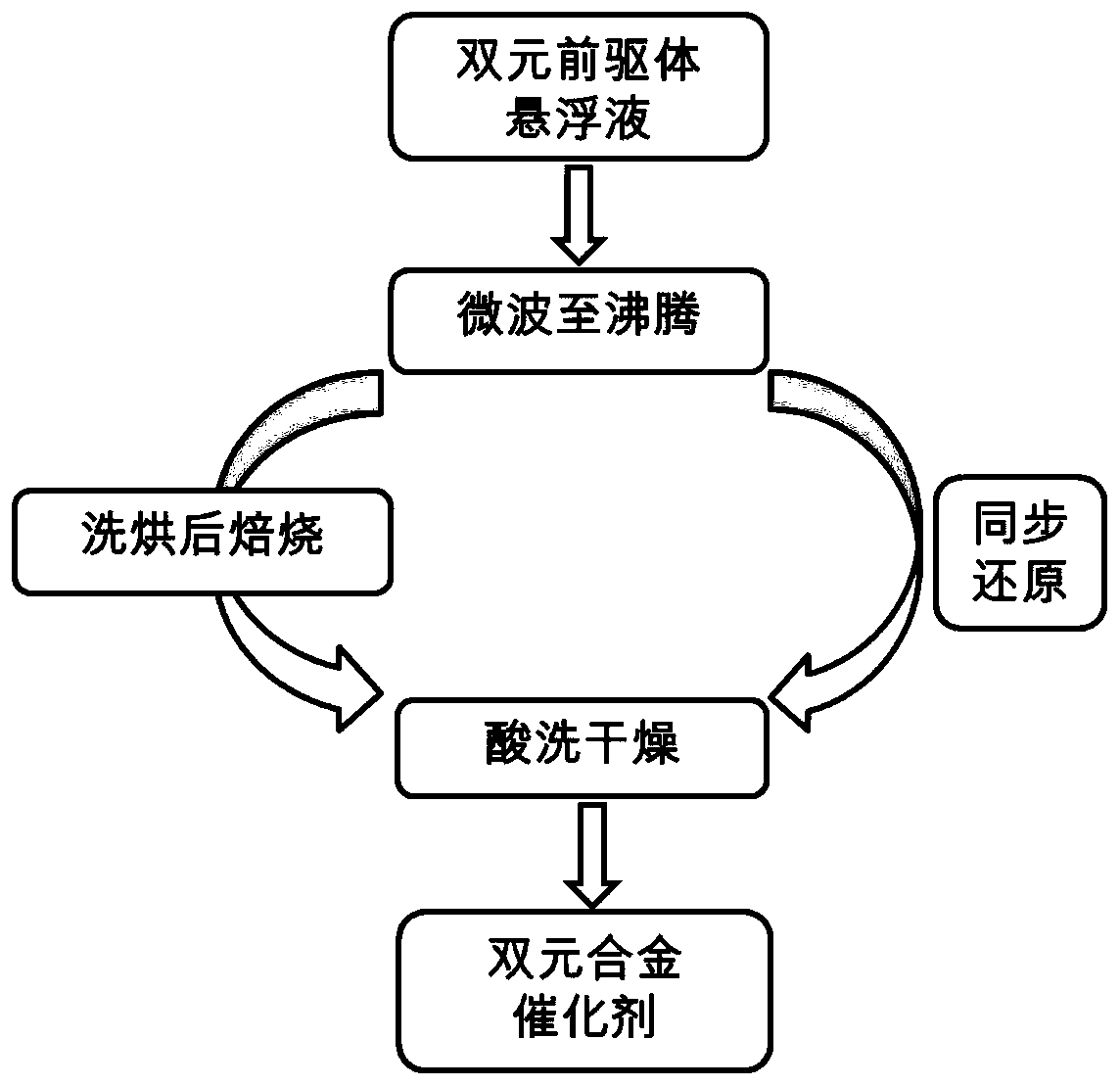

Method used

Image

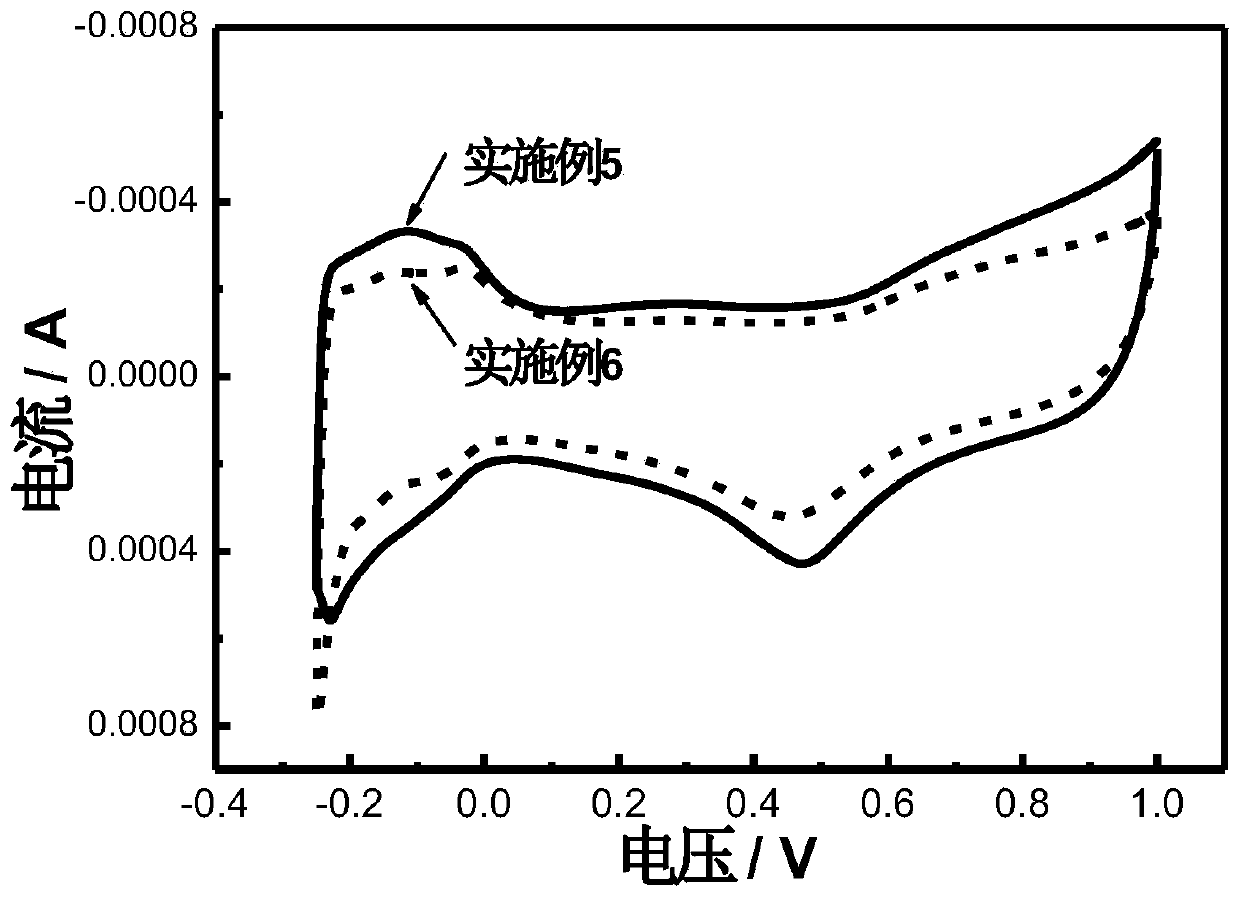

Examples

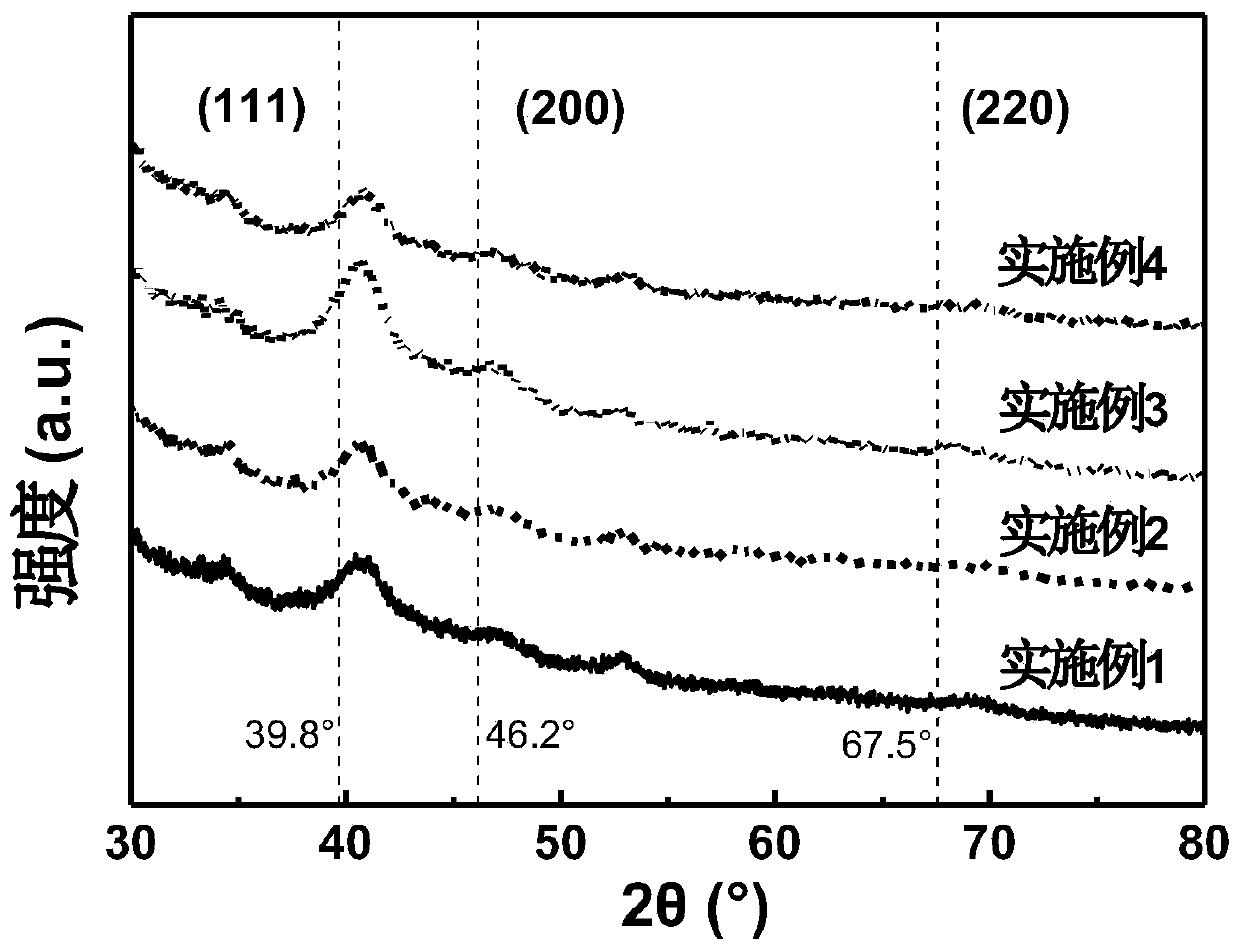

Embodiment 1

[0029] A microwave preparation method for a fuel cell binary alloy catalyst, comprising the steps of: weighing 0.24g carbon carrier, measuring 52mL of 5.2g / L ethylene glycol solution of chloroplatinic acid, 10mL of 29.1g / L cobalt chloride ethylene glycol solution, ultrasonically dispersed in 120mL of ethylene glycol to make a suspension, add 12mL of aqueous solution containing 2g of sodium hydroxide to the suspension, stir for 10min, put it into a microwave oven with a power of 1000W and heat it to boiling, and drop to After standing still at room temperature for 30 minutes, add 18 mL of sulfuric acid with a concentration of 6 mol / L, let stand for 12 hours, centrifuge and wash, and blow dry at 80°C to obtain catalyst powder.

Embodiment 2

[0031] A microwave preparation method for a fuel cell binary alloy catalyst, comprising the steps of: weighing 5g of carbon carrier, measuring 50mL of ethylene glycol solution of 100g / L chloroplatinic acid, 100mL of 60g / L cobalt nitrate in ethylene glycol Solution, ultrasonically dispersed in 2L ethylene glycol to make a suspension, add 360mL of aqueous solution containing 40g of sodium hydroxide to the suspension, stir for 30min, put it into a microwave oven with a power of 6000W, heat it to boiling, and let it stand at room temperature After 30 minutes, 60 mL of sulfuric acid with a concentration of 18.4 mol / L was added, left to stand for 12 hours, centrifuged and washed, and dried by blowing at 60°C to obtain catalyst powder.

Embodiment 3

[0033] A kind of microwave preparation method of fuel cell binary alloy catalyst, comprises the following steps: take by weighing 0.4g carbon carrier, measure the ethylene glycol solution of the 40g / L chloroplatinic acid of 10mL, the ethylene glycol solution of the 30g / L copper sulfate of 5mL Alcohol solution, ultrasonically dispersed in 400mL of ethylene glycol to make a suspension, add 120mL of aqueous solution containing 2g of sodium formate and 5g of sodium hydroxide to the suspension, stir for 30min, put it into a microwave oven with a power of 2000W and heat it to boiling, then drop to After standing still at room temperature for 30 minutes, add 100 mL of sulfuric acid with a concentration of 1 mol / L, let stand for 12 hours, centrifuge and wash, and blow dry at 80°C to obtain catalyst powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com