Humidity and pressure dual-response metal-water battery and preparation method thereof

A dual-response, water-battery technology, which is applied to the electrodes of primary batteries, battery electrodes, and immersion batteries, can solve the problems of increasing device risk and cost, single humidity response ability, single stimulus response ability, etc., and achieve good application Potential, meet the needs of intelligence, and the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046]Example 1 Preparation of a metal-water battery with dual responses to humidity and pressure

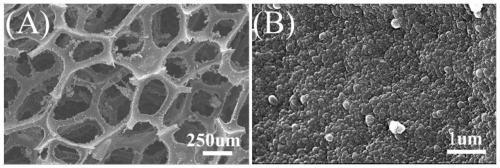

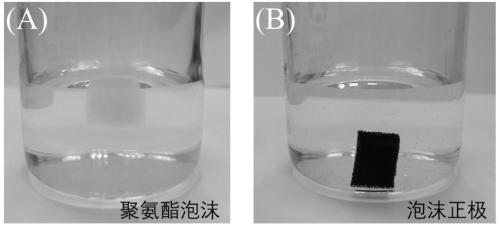

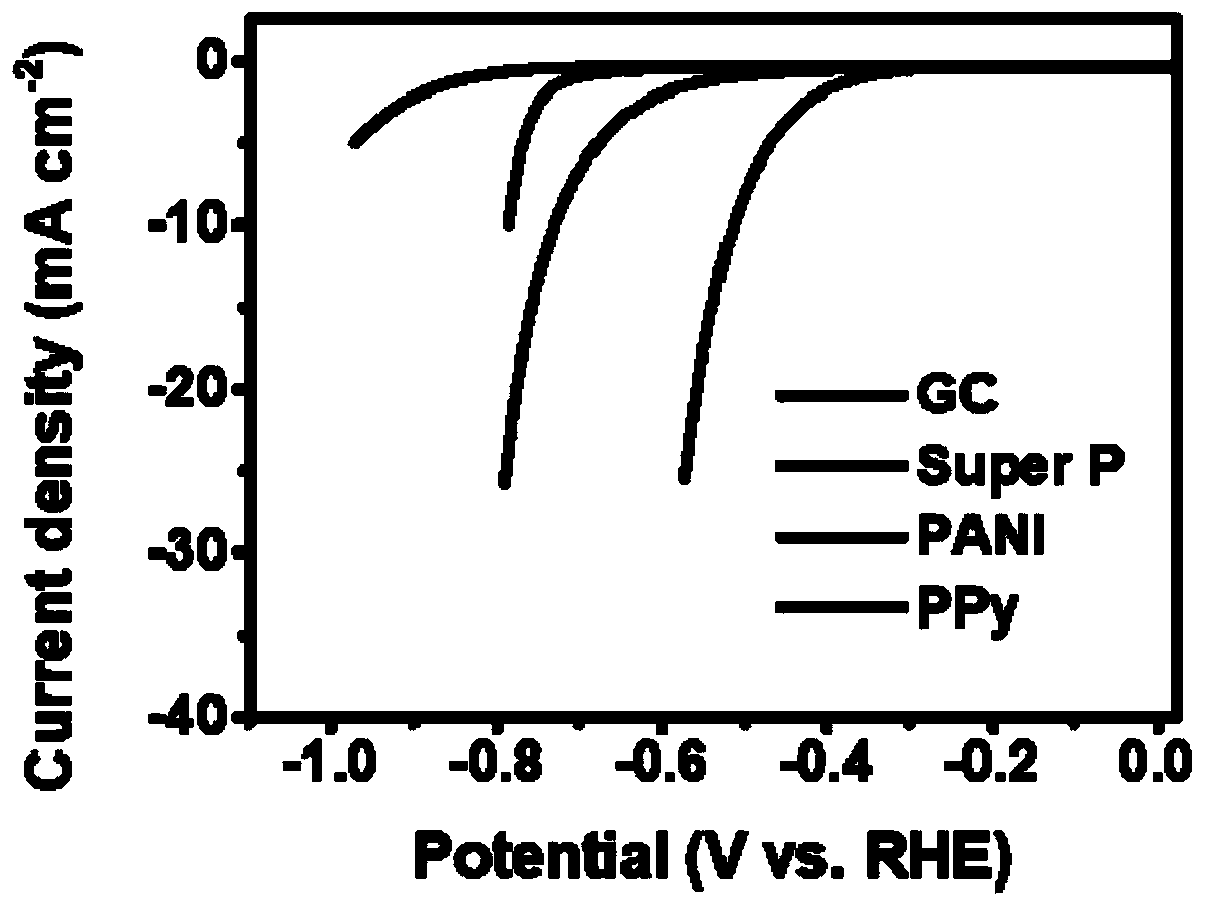

[0047] (1) Preparation of foam cathodes with dual response to humidity and pressure for metal-water batteries

[0048] Dissolve the pyrrole monomer in an aqueous hydrochloric acid solution with a concentration of 0.02M to obtain a pyrrole monomer solution with a concentration of 0.03M; cut the polyurethane foam into 1×1×1cm 3 After immersing in the pyrrole monomer solution, squeeze the polyurethane foam several times to fully absorb the monomer, and refrigerate at 4°C for 6h; then, FeCl 3 Add it into the refrigerated pyrrole monomer solution containing polyurethane foam, carry out chemical oxidation polymerization for 12 hours, wash the foam with deionized water and ethanol, and dry it in an oven at 60°C to obtain the foam positive electrode.

[0049] (2) Preparation of a metal-water battery with dual response to humidity and pressure

[0050] After putting the negative electr...

Embodiment 2

[0051] Example 2 Preparation of a metal-water battery with dual responses to humidity and pressure

[0052] (1) Preparation of foam cathodes with dual response to humidity and pressure for metal-water batteries

[0053] Dissolve the aniline monomer and ammonium persulfate in aqueous hydrochloric acid solution with a concentration of 0.46M to obtain aniline monomer solution and ammonium persulfate solution with a concentration of 0.8M respectively; cut the polyurethane foam into 1×1×1cm 3 After immersing in the aniline monomer solution, squeeze the polyurethane foam several times to fully absorb the monomer, and refrigerate the aniline monomer solution and the ammonium persulfate solution containing the polyurethane foam at 4°C for 6 hours; then, the concentration is 0.8 Add the ammonium persulfate solution of M into the refrigerated aniline monomer solution containing polyurethane foam, carry out chemical oxidation polymerization for 1 hour, wash the foam with deionized water ...

Embodiment 3

[0056] Example 3 Preparation of a metal-water battery with dual responses to humidity and pressure

[0057] Dissolve the pyrrole monomer in aqueous hydrochloric acid solution with a concentration of 0.02M to obtain a solution of pyrrole monomer with a concentration of 0.04M; cut the polyurethane foam into 1×1×1cm 3 After immersing in the pyrrole monomer solution, squeeze the polyurethane foam several times to fully absorb the monomer, and refrigerate at 4°C for 6h; then, FeCl 3 Add it into the refrigerated pyrrole monomer solution containing polyurethane foam, carry out chemical oxidation polymerization for 14 hours, wash the foam with deionized water and ethanol, and dry it in an oven at 60°C to obtain the foam positive electrode.

[0058] (2) Preparation of a metal-water battery with dual response to humidity and pressure

[0059] After putting the negative electrode metal sheet Zn into the negative electrode case of the CR2032 battery case, place the foamed positive electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com