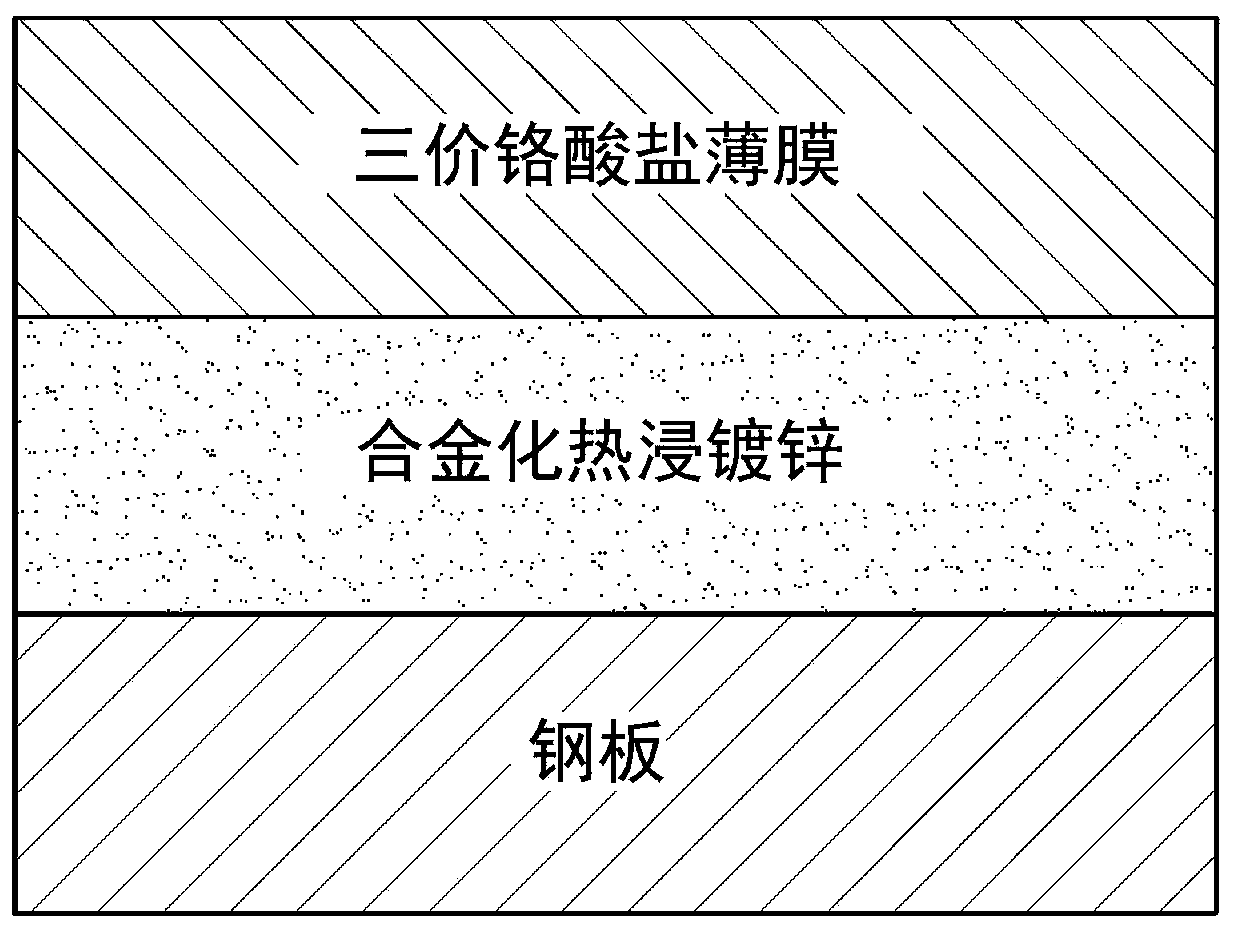

Solution composition containing trivalent chrome for surface treatment of steel sheet, galvanized steel sheet surface-treated with same, and method for manufacturing galvanized steel sheet

A hot-dip galvanized steel sheet and surface treatment technology, applied in hot-dip plating process, superimposed layer plating, coating, etc., can solve the problems of reduced weldability, reduced anti-corrosion effect, reduced film fuel resistance, etc. Achieve the effect of excellent weldability and excellent alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

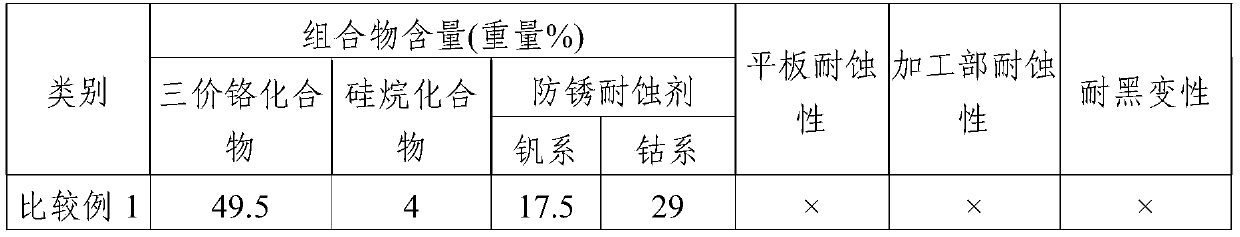

[0075] Changes in physical properties depending on the content of trivalent chromium compounds

[0076] A surface treatment solution composition containing trivalent chromium is prepared as follows: comprising a trivalent chromium compound, a vanadium-based rust and corrosion inhibitor, a cobalt-based rust and corrosion inhibitor, a silane coupling agent and water, wherein the trivalent chromium compound It is prepared by adding chromium phosphate and chromium nitrate in distilled water and reacting at 80°C for 1 hour and then cooling to normal temperature. Cobalt (III) nitrate, the silane coupling agent is a mixture of tetraethyl orthosilicate and 3-glycidoxypropyl trimethoxysilane in a weight ratio of 1:1, and is recorded in the following table 2 The content (based on the solid content of the composition) is mixed to prepare a surface treatment solution composition containing trivalent chromium.

[0077] In addition, in the following examples, the case where the surface tre...

Embodiment 2

[0106] Changes in physical properties depending on the ratio of chromium(III) phosphate and chromium(III) nitrate

[0107] Use the trivalent chromium surface treatment solution composition of Invention Example 3, but the ratio of chromium phosphate (III) and chromium nitrate (III) is controlled to the ratio of chromium phosphate and chromium nitrate recorded in the following table 3, except that In addition, a hot-dip galvanized steel sheet test piece formed with a trivalent chromate inorganic thin film was produced in the same manner as in Example 1.

[0108] About the manufactured test piece, flat plate corrosion resistance and blackening resistance were evaluated by the same method as Example 1, and the evaluation result is described in Table 3.

[0109] [table 3]

[0110]

[0111] *Component content is based on 14% solids.

[0112] As shown in the above-mentioned Table 3, as the proportion of chromium phosphate increases, the effect of improving the corrosion resistan...

Embodiment 3

[0114] Changes in physical properties depending on the content and type of silane compound

[0115] In addition to using chromium nitrate and chromium phosphate as a trivalent chromium compound, vanadium acetylacetonate as a vanadium-based rust and corrosion inhibitor, cobalt (III) nitrate as a cobalt-based rust and corrosion inhibitor, and 1 as a silane coupling agent In addition to mixing the silane compound of tetraethyl orthosilicate and 3-glycidoxypropyl trimethoxysilane in the ratio of 1 (based on the solid content of the composition) in the following table 4, A hot-dip galvanized steel sheet test piece formed with a trivalent chromate inorganic thin film was produced by the same method as in Example 1.

[0116] For the flat plate corrosion resistance, processed portion corrosion resistance and blackening resistance of the manufactured test piece, it was evaluated by the same method as in Example 1, and the alkali resistance, fuel resistance and fingerprint resistance we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com