Fungus food capable of changing corn processing characteristics through ganoderma lucidum fermentation and preparation method thereof

A corn processing and Ganoderma lucidum fermentation technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fungi, etc., can solve the problem of rough taste of corn flour processed products, poor viscoelasticity of corn flour dough, and high amylose content Advanced problems, to achieve the effect of increasing mycelium production, improving the effect of inoculation and cultivation, and increasing the effect of replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

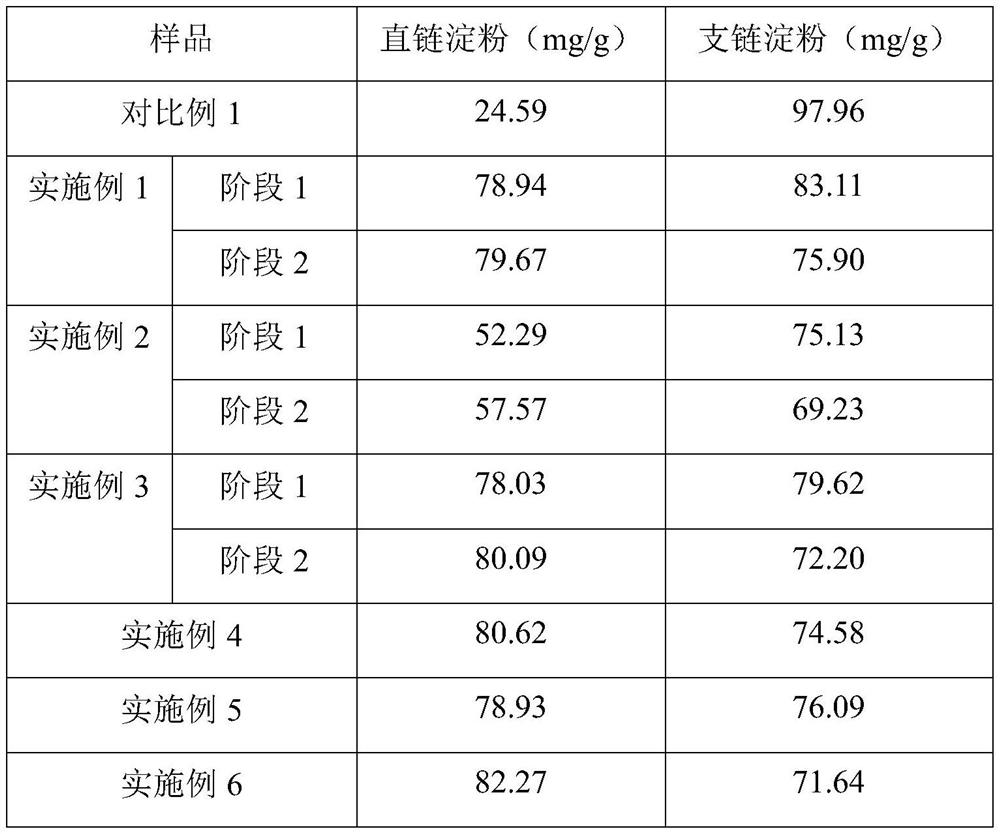

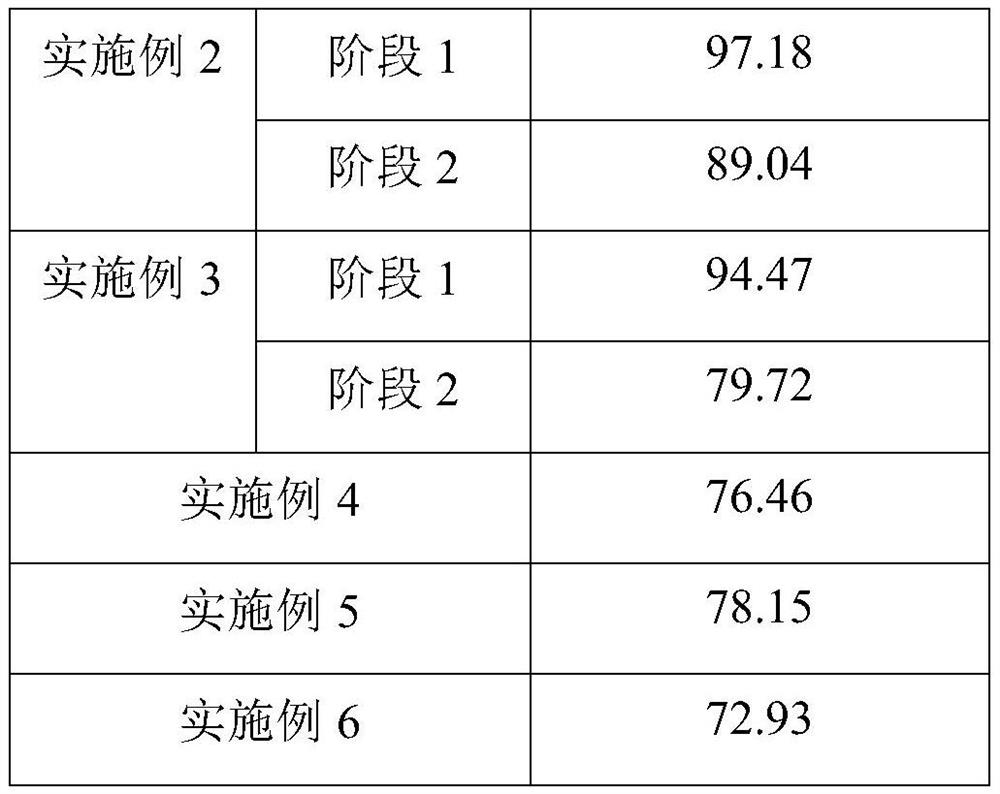

Examples

Embodiment 1

[0028] The preparation method of the bacterium grain which changes the processing characteristic of corn by ganoderma lucidum fermentation comprises the following steps:

[0029] S1. In a sterile environment, inoculate 1 ring of Ganoderma lucidum strain into 250 mL of PDB medium, and culture it on a shaking table at a temperature of 28° C. and a rotation speed of 145 r / min for 4 days to obtain activated Ganoderma lucidum strain, wherein, The preparation method of PDB medium is as follows: Weigh 35g of solid PDB medium and pour it into an Erlenmeyer flask, add 1000mL of distilled water, stir well to dissolve it completely, titrate with 4mol / L hydrochloric acid to pH 4.5, and autoclave at 121°C Bacteria for 30min, cooled to room temperature;

[0030] S2. Wash the corn kernels, soak them in boiling water for 2 hours, take them out and drain them, add dextrose accounting for 3% of the mass of corn kernels, magnesium sulfate heptahydrate accounting for 0.2% of the mass of corn kern...

Embodiment 2

[0035] The preparation method of the bacterium grain which changes the processing characteristic of corn by ganoderma lucidum fermentation comprises the following steps:

[0036] S1. In a sterile environment, inoculate 2 rings of Ganoderma lucidum into 500mL of PDB medium, culture on a shaker at a temperature of 25°C and a rotation speed of 145r / min for 4 days to obtain activated Ganoderma lucidum, wherein, The preparation method of PDB medium is as follows: Weigh 35g of solid PDB medium and place it in a conical flask, add 1000mL of distilled water, stir well to dissolve it completely, titrate with 4mol / L hydrochloric acid to pH 4.5, and autoclave at 121°C Bacteria for 30min, cooled to room temperature;

[0037] S2. Wash the corn kernels, soak them in boiling water for 2 hours, take them out and drain them, add dextrose accounting for 3% of the mass of corn kernels, magnesium sulfate heptahydrate accounting for 0.2% of the mass of corn kernels, and diphosphate diphosphate acc...

Embodiment 3

[0042] The preparation method of the bacterium grain which changes the processing characteristic of corn by ganoderma lucidum fermentation comprises the following steps:

[0043] S1. In a sterile environment, inoculate 1 ring of Ganoderma lucidum strain into 250 mL of PDB medium, and culture it on a shaking table at a temperature of 30° C. and a rotation speed of 145 r / min for 3 days to obtain activated Ganoderma lucidum strain, wherein, The preparation method of PDB medium is as follows: Weigh 35g of solid PDB medium and place it in a conical flask, add 1000mL of distilled water, stir well to dissolve it completely, titrate with 4mol / L hydrochloric acid to pH 4.5, and autoclave at 121°C Bacteria for 30min, cooled to room temperature;

[0044]S2. Wash the corn kernels, soak them in boiling water for 2 hours, take them out and drain them, add dextrose accounting for 3% of the mass of corn kernels, magnesium sulfate heptahydrate accounting for 0.2% of the mass of corn kernels, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com