Preparation method of nitrogen-doped porous biomass charcoal

A biochar and nitrogen-doped technology, which is applied in chemical instruments and methods, water pollutants, alkali metal compounds, etc., can solve the problems of low yield of nitrogen-doped biochar and poor adsorption performance of antibiotic pollutants, etc. , to achieve the effect of low production cost, low equipment requirements and high adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0043] Specific embodiment one: the preparation method of a kind of nitrogen-doped porous biochar of this embodiment is carried out according to the following steps:

[0044] One, join chitosan into water, add glacial acetic acid solution to promote chitosan dissolving simultaneously, obtain chitosan solution; The mass of chitosan in the described chitosan solution and the volume ratio of water are 0.01g: 1mL ; The volume concentration of the glacial acetic acid solution is 2%, and the volume ratio of the glacial acetic acid solution and water is 0.1:1;

[0045] 2. Mix 100mL of the chitosan solution obtained in step 1 with 100mL of sodium lignosulfonate solution with a concentration of 0.01g / mL and a pH value of 12, and then centrifuge at a speed of 8000r / min for 5min to remove the supernatant liquid, resulting in a precipitate;

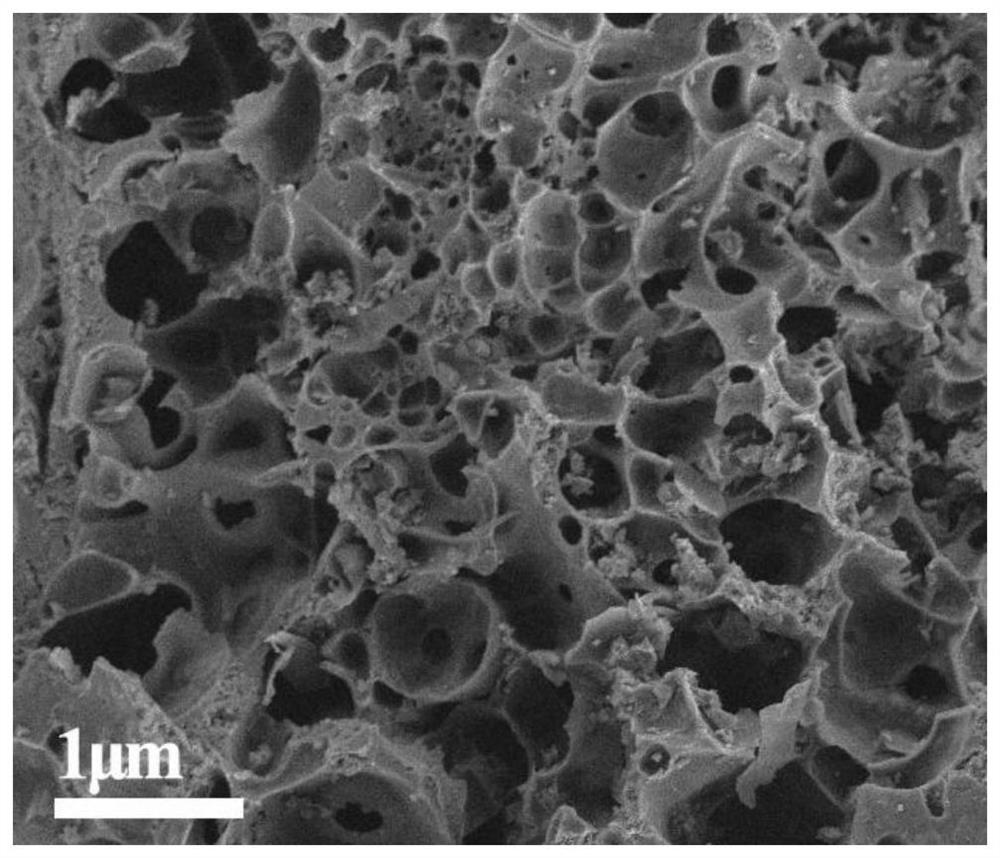

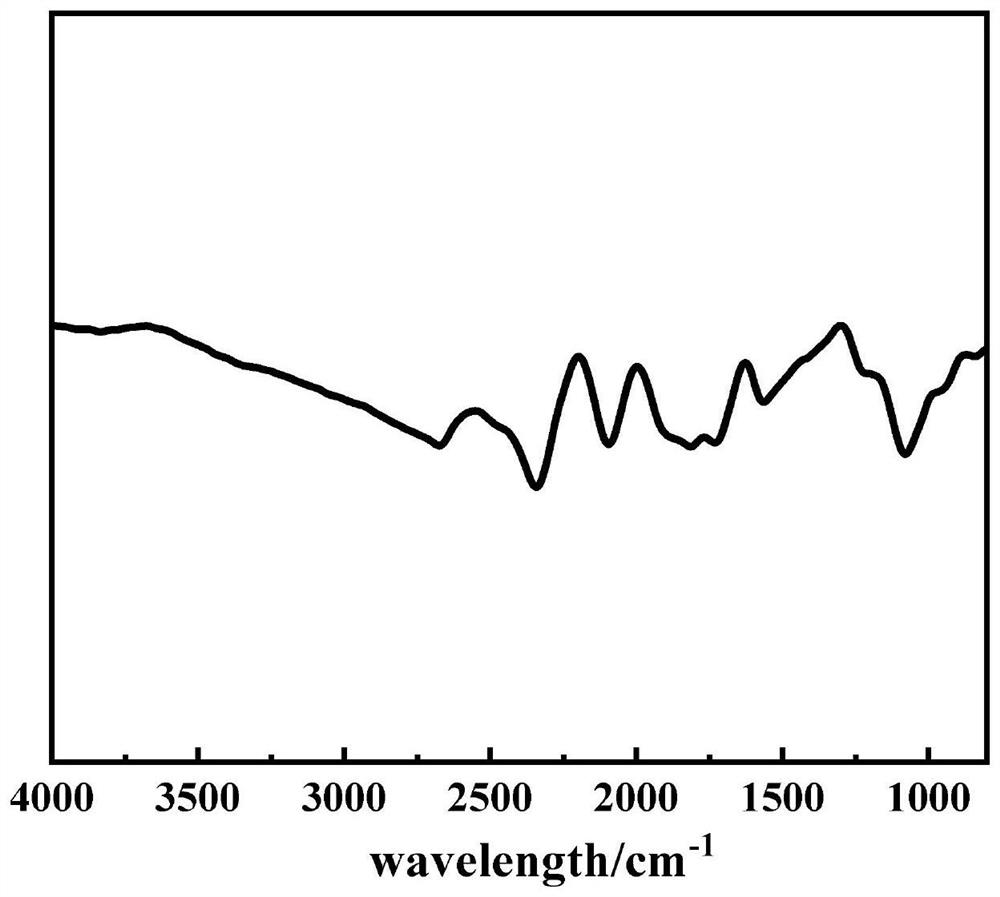

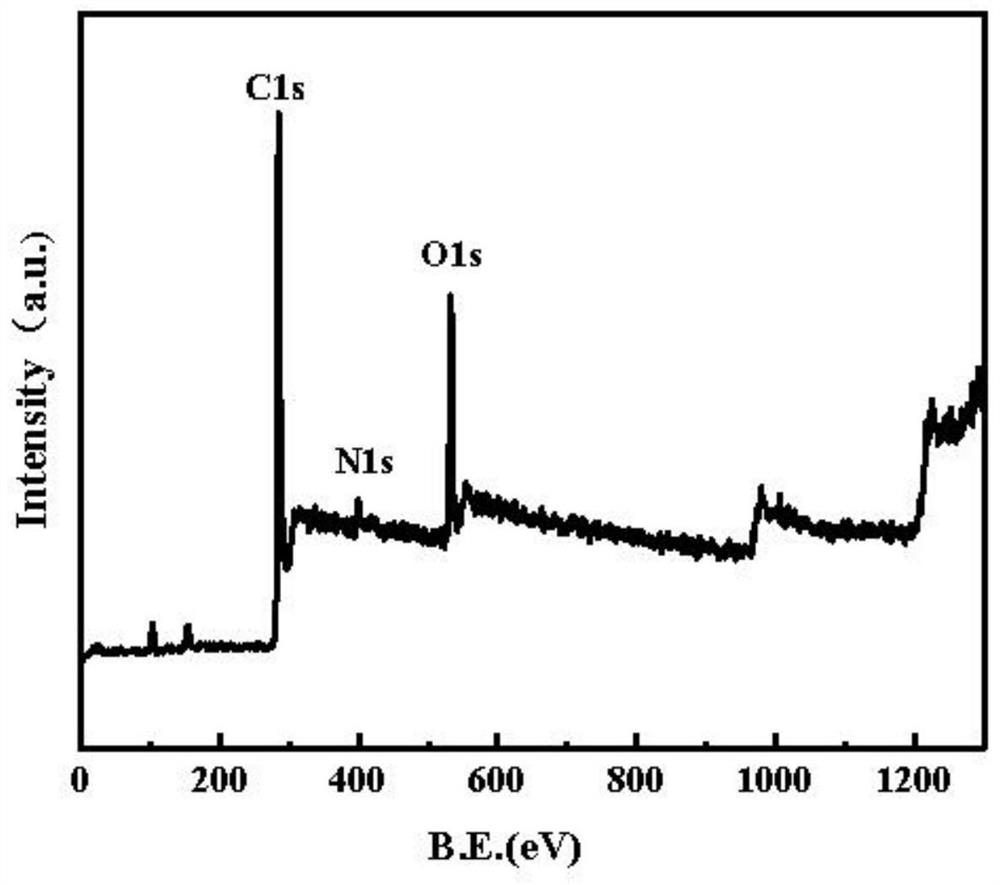

[0046] 3. The precipitate obtained in step 2 is first dried at 50° C., and then calcined. After the calcining is completed, it is soaked in a potas...

specific Embodiment approach 2

[0048] Embodiment 2: This embodiment is different from Embodiment 1 in that: the pH value of the sodium lignosulfonate solution described in step 2 is 7. Other steps and parameters are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com