Assembled inverted arch unit, assembled inverted arch structure and construction method

A construction method and assembly-type technology, which is applied in vertical shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of affecting the construction speed of inverted arches, prolonging the time, and requiring large space for on-site operations, so as to facilitate safe and rapid construction , better water-stopping effect, and the effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

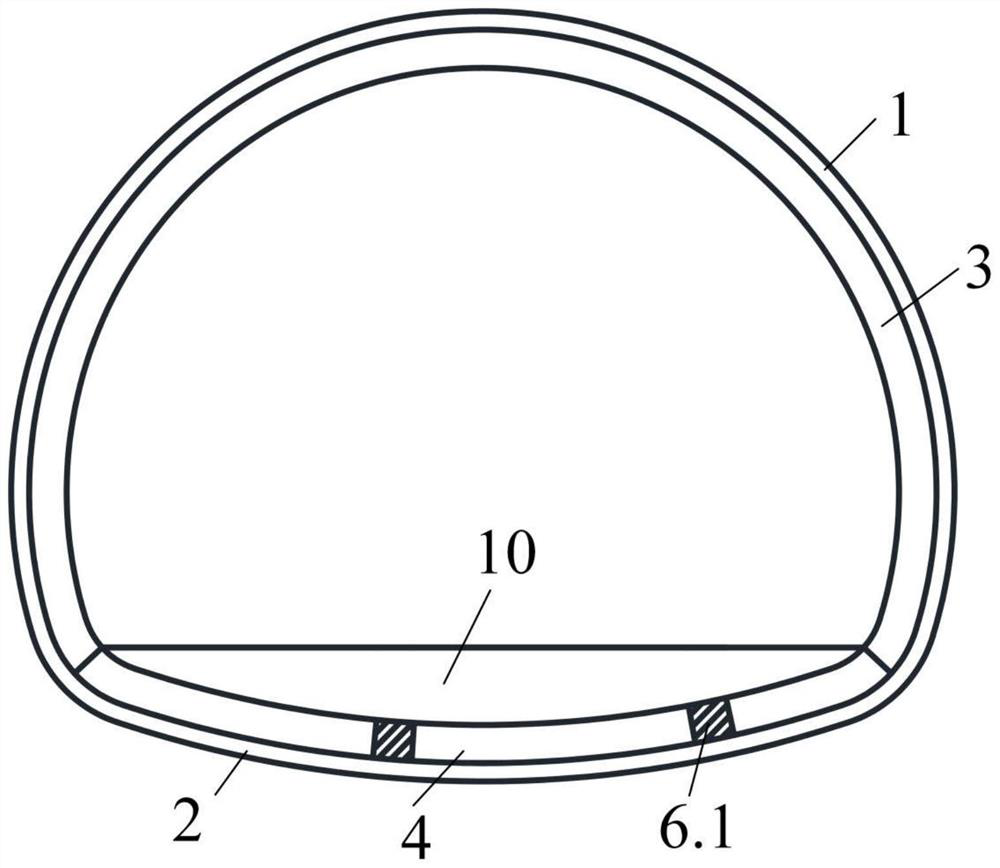

[0051] like figure 1 As shown, the tunnel support structure includes primary support and secondary lining, wherein the primary support includes the primary support of the arch wall 1 and the primary support of the inverted arch 2, and the secondary lining includes the secondary lining of the arch wall 3 and the secondary lining of the inverted arch 4. What is improved in the assembled inverted arch structure of this device is figure 1 The middle invert arch is lined with 4.

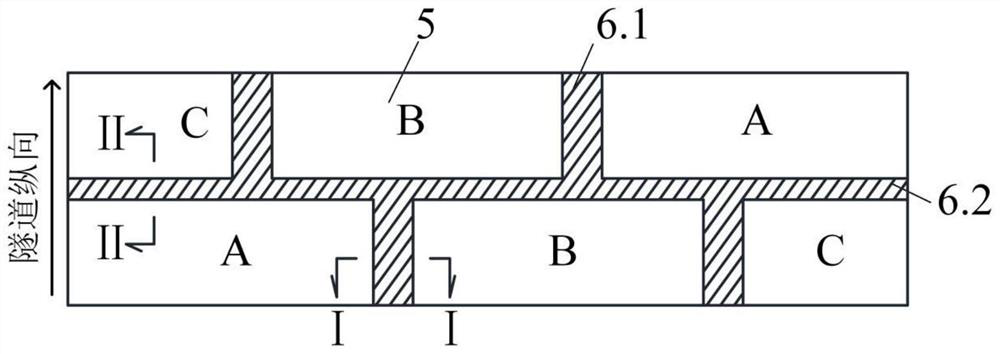

[0052] This structure adopts an assembled structure, and each ring of inverted arch two linings 4 is assembled by a plurality of inverted arch units 5, and the inverted arch units 5 are all prefabricated. The quantity of the inverted arch units 5 of every ring inverted arch two linings 4 is affected by the mechanical conditions of hoisting, and the inverted arch units 5 are less in number, so the size and weight of each inverted arch unit 5 are larger, and then better hoisting conditions are required. A...

Embodiment 2

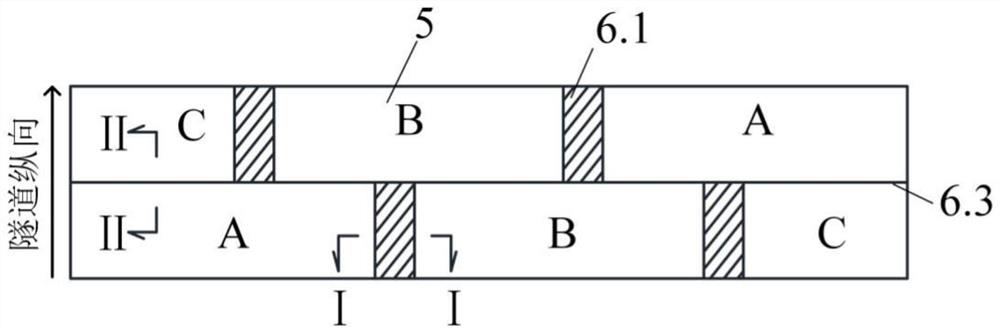

[0070] As shown in Figure 2 (b), the difference between the present embodiment and Embodiment 1 is that the longitudinal main rib of the assembled inverted arch unit 5 does not extend from both sides of the inverted arch unit 5, and the adjacent inverted arch two lining rings are longitudinally Tight splicing, but due to the close splicing of adjacent inverted arch two lining rings, there will still be a longitudinal assembly seam 6.3, so by filling epoxy cement in the longitudinal assembly seam 6.3, the inverted arch unit is connected into an inverted arch as a whole. At the same time, a waterstop is reserved at the bottom of the longitudinal connection surface of the inverted arch unit 5 (not marked in the figure), and its longitudinal connection surface does not need to be chiseled, but only needs to remove the debris and scum on the surface.

[0071] In the prefabricated inverted arch structure connected by the back-casting belt, longitudinally adjacent inverted arch two li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com