Rectangular optical frequency comb generation system based on on-chip silicon nitride micro-ring

A technology of silicon nitride microrings and optical frequency combs, applied in optics, nonlinear optics, instruments, etc., can solve the problems of comb tooth bandwidth limitation, increase difficulty, increase device cost complexity, etc., and reduce the pressure of subsequent processing , improve energy conversion efficiency, and solve the effect of edge power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

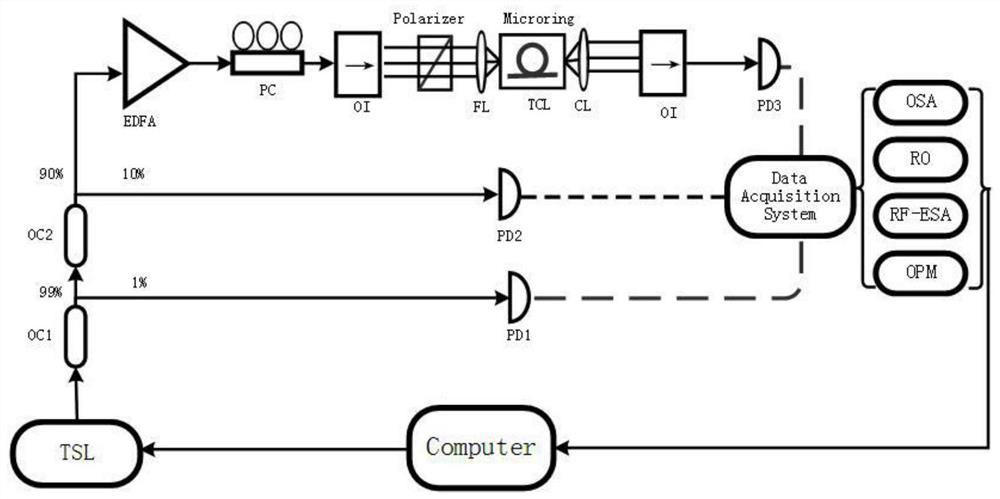

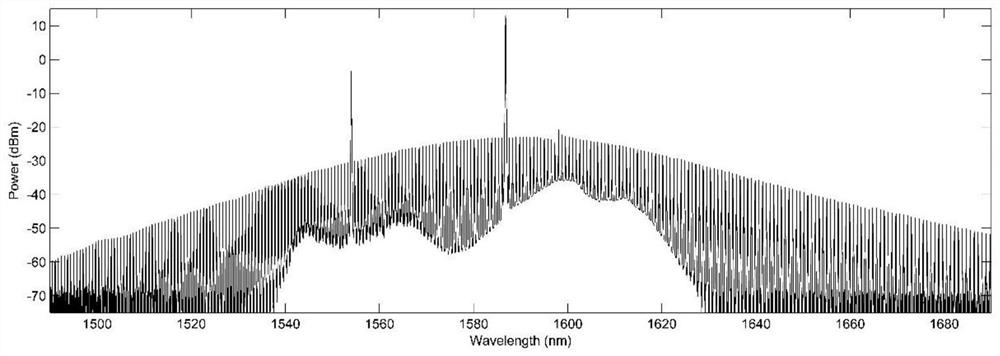

[0058] First, the laser light emitted from the tunable laser (TLS, 1591nm) passes through two optical couplers (OC1 and OC2), and then amplified by the erbium-doped fiber amplifier (EDFA), and the propagation direction is controlled by the polarization controller (PC). The optical isolator (OI) prevents the backward transmission light in the optical path from affecting the light source, and finally enters the Si through the polarizer 3 N 4 Microring resonator (200 microns in diameter). After a series of operations such as amplification and polarization control, the intense laser enters Si with a high quality factor (Q=1500000) and a temperature of 328.15K 3 N 4 When the microring resonator is used, the optical nonlinear effect is generated in the microcavity. When the optical nonlinear effect and the normal group velocity dispersion (89ps 2 / km) reached equilibrium, a femtosecond mode-locked pulse, the time-dissipative soliton, was generated in the microcavity. Finally, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com