Polyurethane cross-linked reduced graphene oxide composite conductive film and preparation method and application thereof

A technology of graphene composite and conductive film, which is applied in the direction of equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, and conductive layers on insulating carriers. , Low electrical conductivity and other issues, to achieve high use value, good electrical conductivity, and meet the needs of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

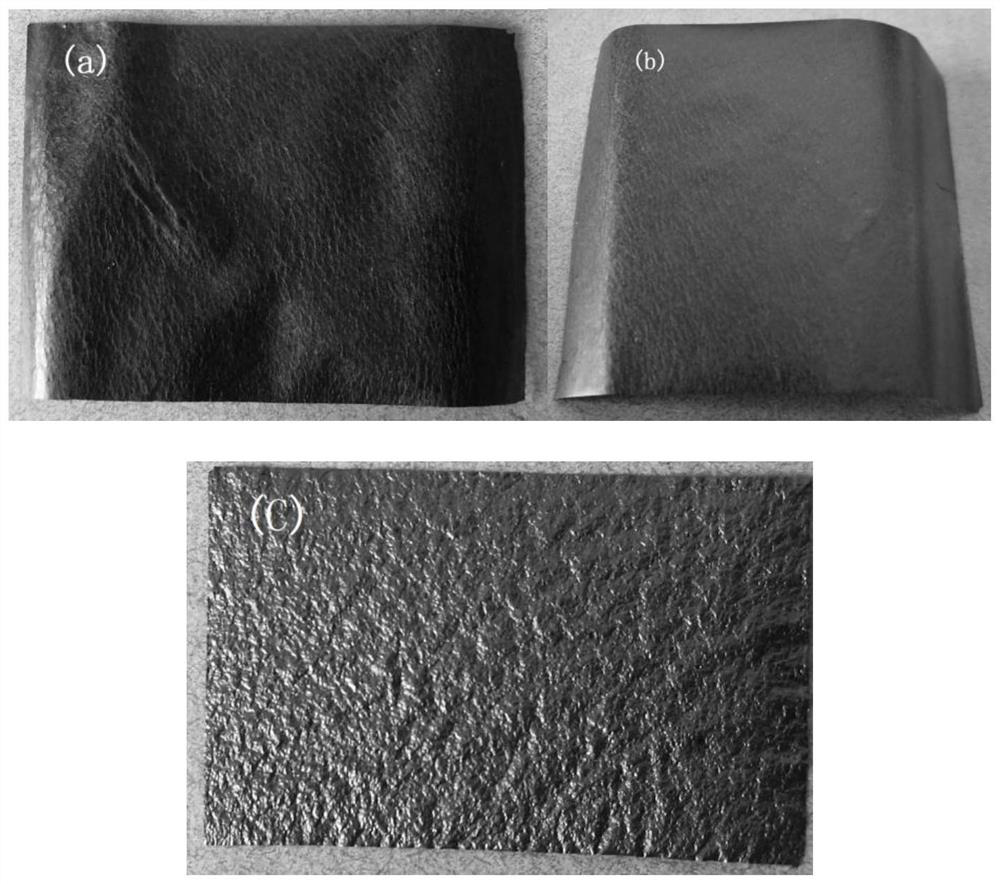

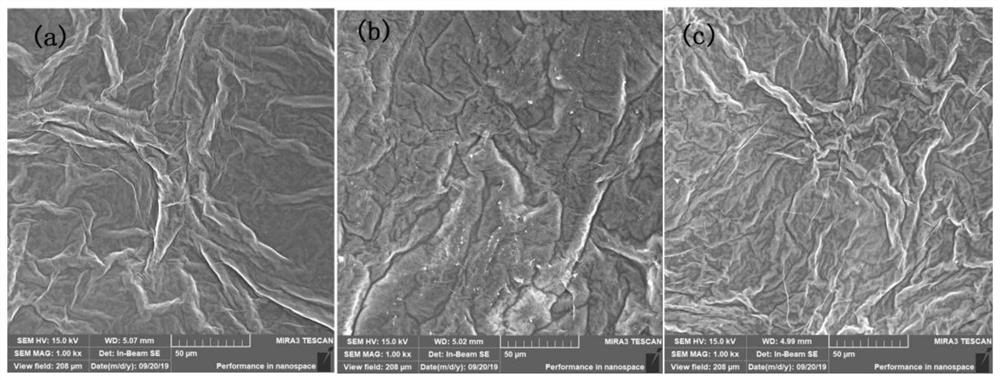

[0038] A polyurethane cross-linked reduced graphene oxide composite conductive film is formed by cross-linking polyurethane and reduced graphene oxide, wherein the mass fraction of polyurethane in the polyurethane cross-linked reduced graphene oxide composite conductive film is 5%.

[0039]A preparation method of the polyurethane cross-linked reduced graphene oxide composite conductive film in the above-mentioned embodiments of the present invention, comprising the following steps:

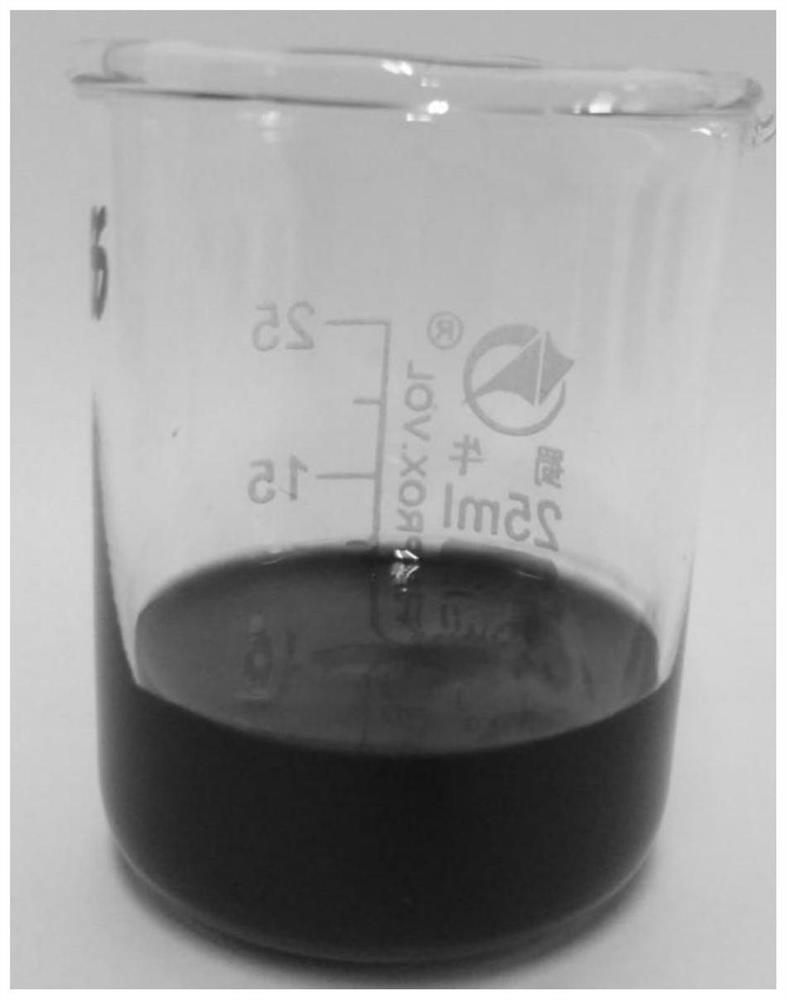

[0040] (1) Get 10mL of single-layer graphene oxide aqueous phase solution with a concentration of 13.8mg / mL (the average radial size of single-layer graphene oxide in this single-layer graphene oxide aqueous phase solution is 40 μm to 50 μm, and the single-layer ratio >95%), put it on a magnetic stirrer and stir rapidly; during the stirring process, first add 0.35ml of deionized water, stir for 10min, and then add 6.9mL of water-based polyurethane aqueous phase solution with a concentration of 1mg / ...

Embodiment 2

[0046] A polyurethane cross-linked reduced graphene oxide composite conductive film is basically the same as the polyurethane cross-linked reduced graphene oxide composite conductive film in Example 1, the only difference being: the polyurethane cross-linked reduced graphene oxide composite conductive film in Example 2 The mass fraction of polyurethane is 1%.

[0047] The preparation method of the polyurethane cross-linked reduced graphene oxide composite conductive film of embodiment 2 is basically the same as the preparation method of the polyurethane cross-linked reduced graphene oxide composite conductive film in embodiment 1, the only difference being: the preparation method of embodiment 2 The amount of the aqueous polyurethane solution in water is 1.38mL.

Embodiment 3

[0049] A polyurethane cross-linked reduced graphene oxide composite conductive film is basically the same as the polyurethane cross-linked reduced graphene oxide composite conductive film in Example 1, the only difference being: the polyurethane cross-linked reduced graphene oxide composite conductive film in Example 3 The mass fraction of polyurethane is 10%.

[0050] The preparation method of the polyurethane cross-linked reduced graphene oxide composite conductive film of embodiment 3 is basically the same as the preparation method of the polyurethane cross-linked reduced graphene oxide composite conductive film in embodiment 1, the only difference being: the preparation method of embodiment 3 The amount of the aqueous polyurethane aqueous phase solution is 13.8mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Smudge thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com