High-temperature-resistant halogen-free flame-retardant cable

A flame retardant cable, high temperature resistance technology, applied in the field of halogen-free flame retardant cable, high temperature halogen-free flame retardant cable, can solve the problem of tensile strength and elongation at break decrease, cable burning damage, low flame retardant grade and other problems, to achieve the effect of improving resistance, improving tensile strength, and strong flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

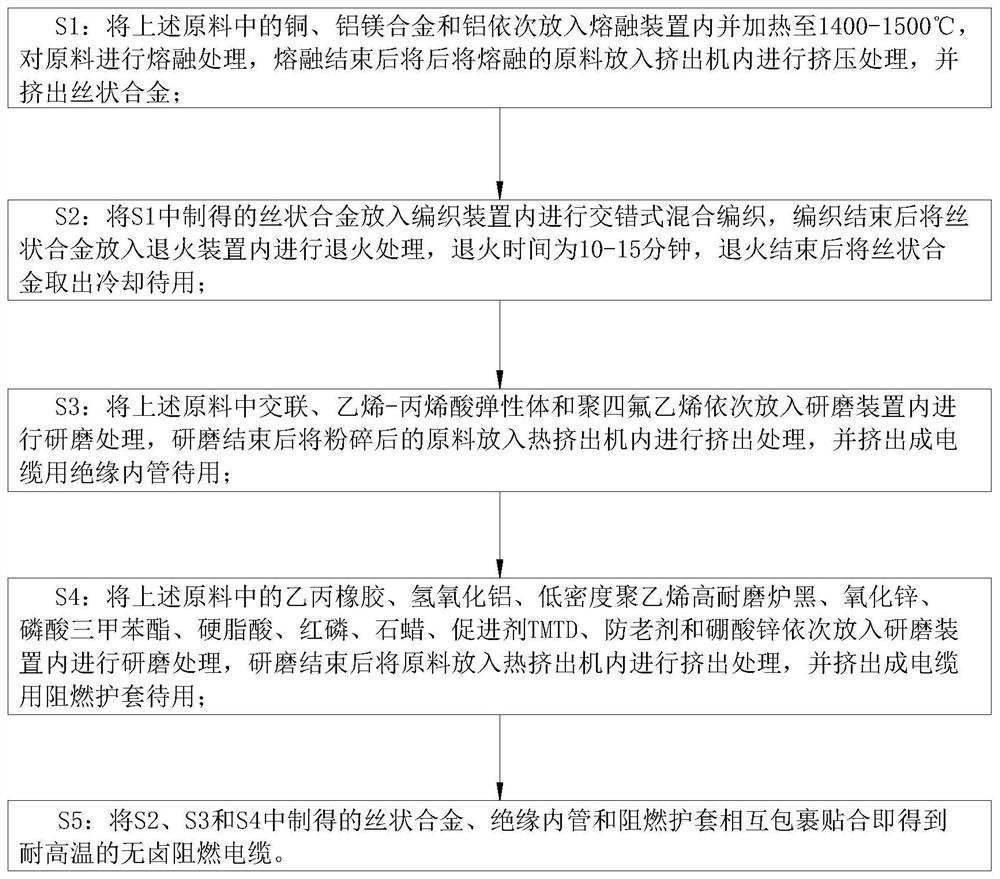

Method used

Image

Examples

Embodiment approach

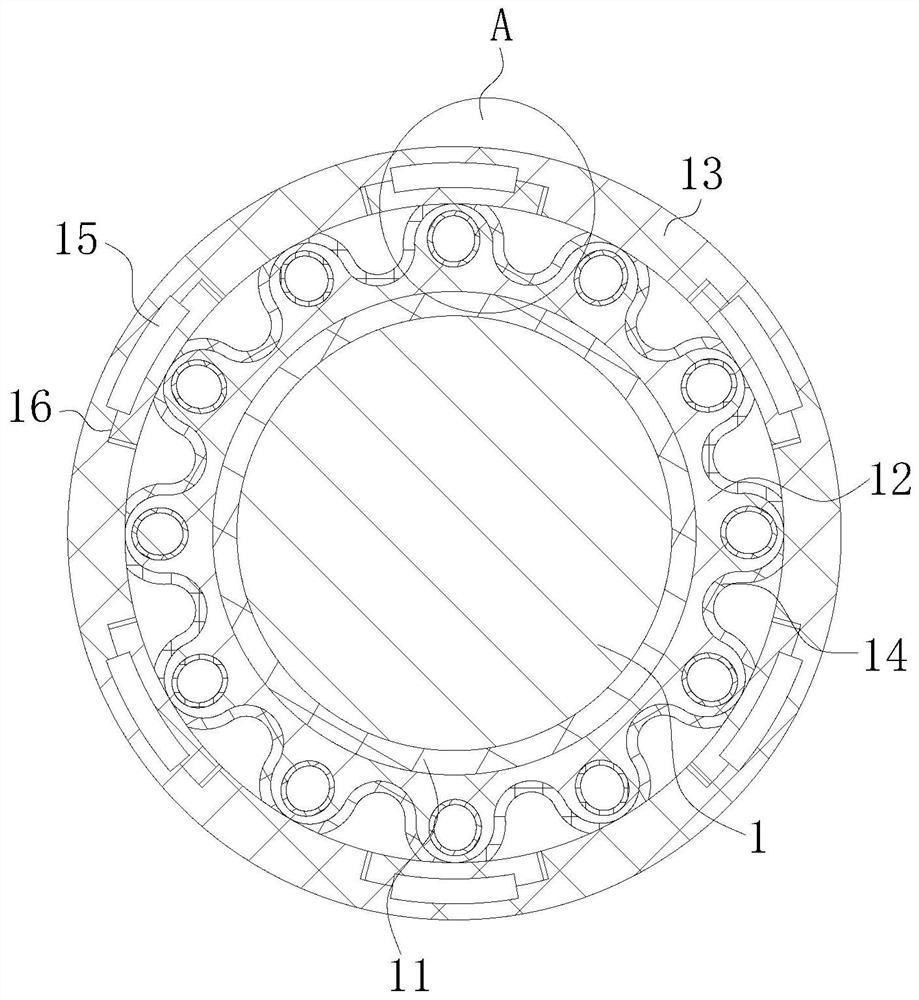

[0043] As an embodiment of the present invention, the accelerator contains 2-3 kinds of ammonium polyphosphate, phosphoric acid ester, pentaerythritol, melamine and expanded graphite;

[0044] The ammonium polyphosphate contained in the accelerator is a non-halogen flame retardant with excellent performance. In the present invention, it can not only play the role of fire prevention and flame retardancy, but also improve the mechanical properties and tensile strength of the cable. The accelerator contains The phosphate ester is an ester derivative of phosphoric acid, which is a tribasic acid and has strong adhesion. In the present invention, the mixing effect between raw materials can be enhanced, and the flame retardancy of the cable can also be improved. Accelerator The melamine in it is a triazine-type nitrogen-containing heterocyclic organic compound, which can be used as a flame retardant in the present invention. Through the mutual cooperation of the above-mentioned raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com