Magnesium-antimony-based thermoelectric element and preparation method and application thereof

A thermoelectric element, magnesium-antimony-based technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device parts, thermoelectric device junction lead wire materials, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Mg chips, Mn powder, Bi particles, Sb particles, Te powder according to the chemical formula Mg 3.275 mn 0.025 Bi 0.5 Sb 1.49 Te 0.01 After weighing, it was ball milled for 12 hours to obtain the mixture powder, which was sintered into a cylindrical bulk material with a thickness of 1.2 mm and a diameter of 12.7 mm by spark plasma sintering. The sintering process is as follows: the heating rate is 50°C per minute, the temperature is kept at 600°C for 2 minutes, and then the temperature is raised to 800°C for 2 minutes and then cooled with the furnace. The pressure during the sintering process is 50Mpa.

[0032] (2) Mg scrap and Cu powder according to the chemical formula Mg 2 Cu was weighed and ball milled for 6 hours to obtain transition layer powder.

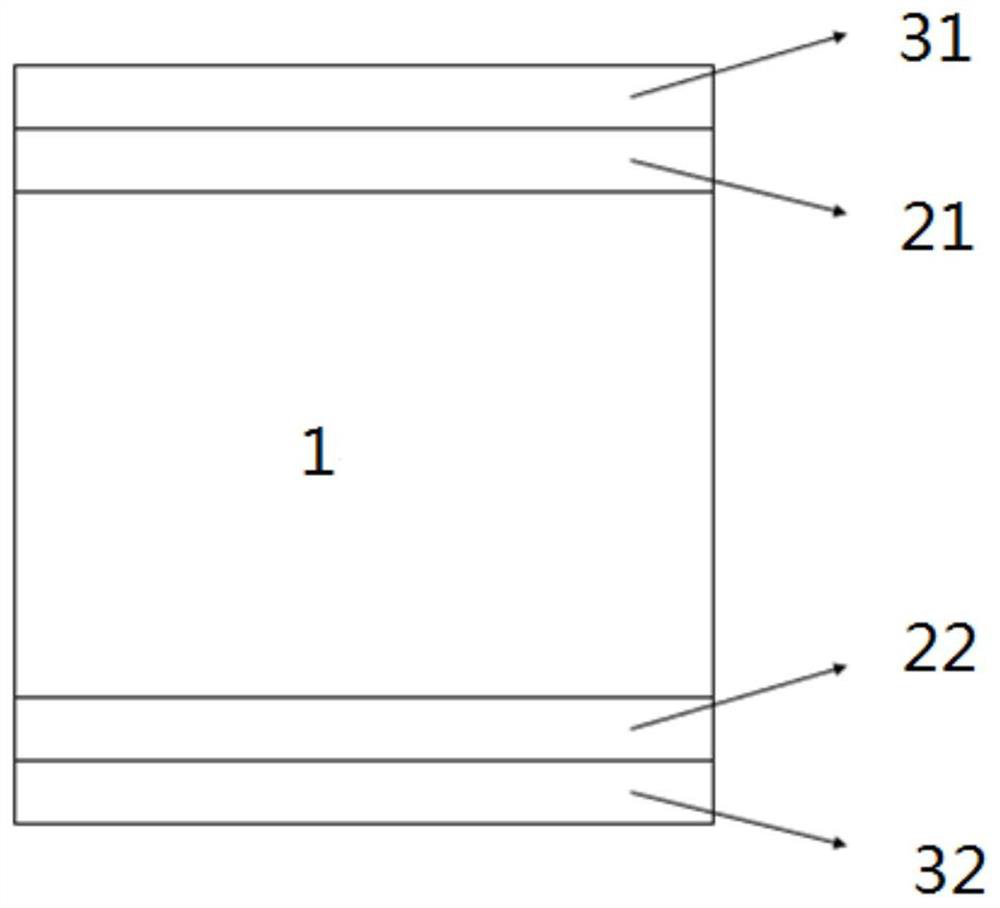

[0033] (3) The base thermoelectric material, the transition layer powder and the copper foil as the electrode layer are according to figure 1 The positions shown are placed in the mold for sintering. The sint...

Embodiment 2

[0036] (1) Mg chips, Mn powder, Bi particles, Sb particles, Te powder according to the chemical formula Mg 3.275 mn 0.025 Bi 0.5 Sb 1.49 Te 0.01 After weighing, it was ball-milled for 12 hours to obtain the mixture powder, which was sintered by spark plasma to form a matrix layer of a cylindrical bulk magnesium-antimony-based thermoelectric material with a thickness of 1.2 mm and a diameter of 12.7 mm. The sintering process is as follows: the heating rate is 50°C per minute, the temperature is kept at 600°C for 2 minutes, and then the temperature is raised to 800°C for 2 minutes and then cooled with the furnace. The pressure during the sintering process is 50Mpa.

[0037] (2) Put the magnesium-antimony-based thermoelectric material matrix layer prepared in step (1) into a beaker filled with alcohol, clean it with an ultrasonic cleaner for 20 minutes, then dry it with a hair dryer or a drying device, and then fix it on In a magnetron sputtering apparatus with copper and mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com