Method of reducing decomposition of chlorophyll in alfalfa silage

A chlorophyll and alfalfa technology, applied in the field of silage, can solve the problems of unclear chlorophyll degradation and metabolism rules, and achieve the effects of increasing the in vitro dry matter degradation rate, improving the fermentation quality, and slowing down the loss of chlorophyll.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with experiment the present invention will be further described:

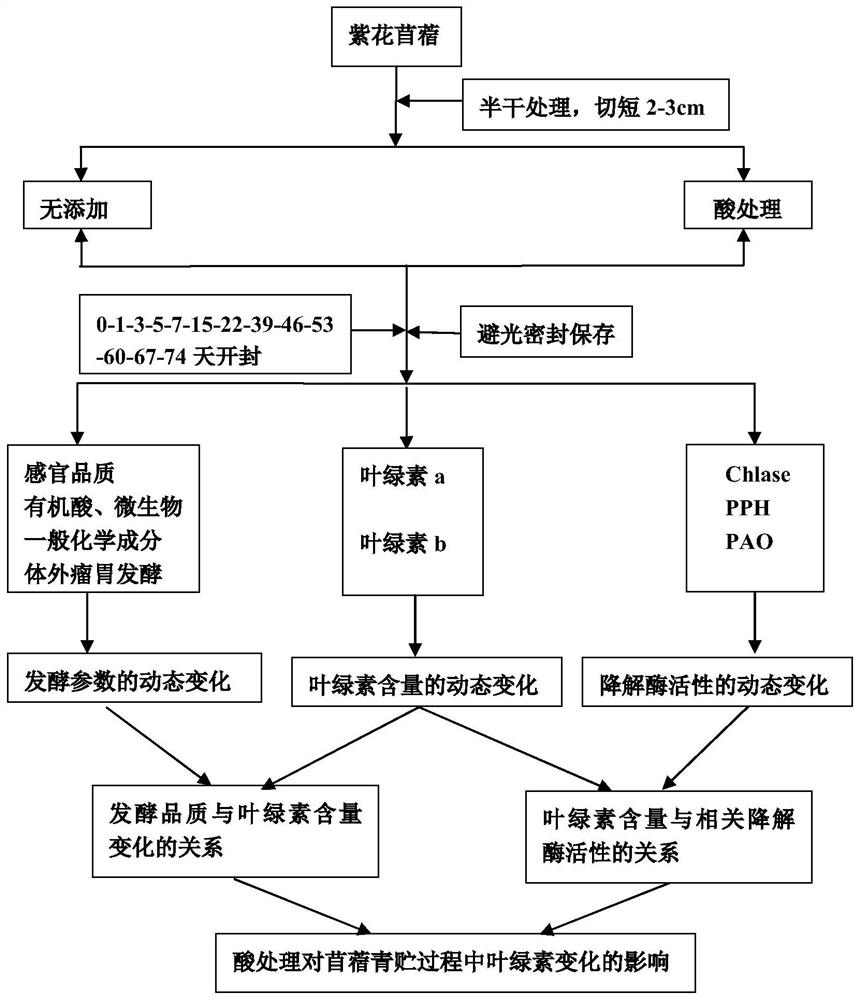

[0014] A method for reducing the decomposition of chlorophyll in alfalfa silage comprises the following steps: the alfalfa raw material is dried in the dark and ventilated place until it is semi-dried, with a water content of about 50%, chopped to 2-3 cm, pressed with sulfuric acid of different concentrations and hydrochloric acid of different concentrations Prepare mixed acid by mixing at a certain volume ratio. Add a certain amount of mixed acid to alfalfa. After processing the sample, weigh 200g and put it into a black polyethylene bag with a size of 16×25cm. Seal the package with a vacuum machine and store it in a dark environment at room temperature. Small-scale fermentation was carried out under , respectively in 0, 1, 3, 5, 7, 15, 22, 39, 46, 53, 60, 67, 74 days unsealed, and 3 bags were unsealed at each time.

[0015] This application aims at the influence of different concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com