Glass-ceramic and its tempering method and application

A kind of glass-ceramic, glass technology, applied in glass tempering, glass manufacturing equipment, electrical equipment shell/cabinet/drawer and other directions, can solve the problem of small degree of ion exchange, temperature drop, not suitable for glass-ceramic and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

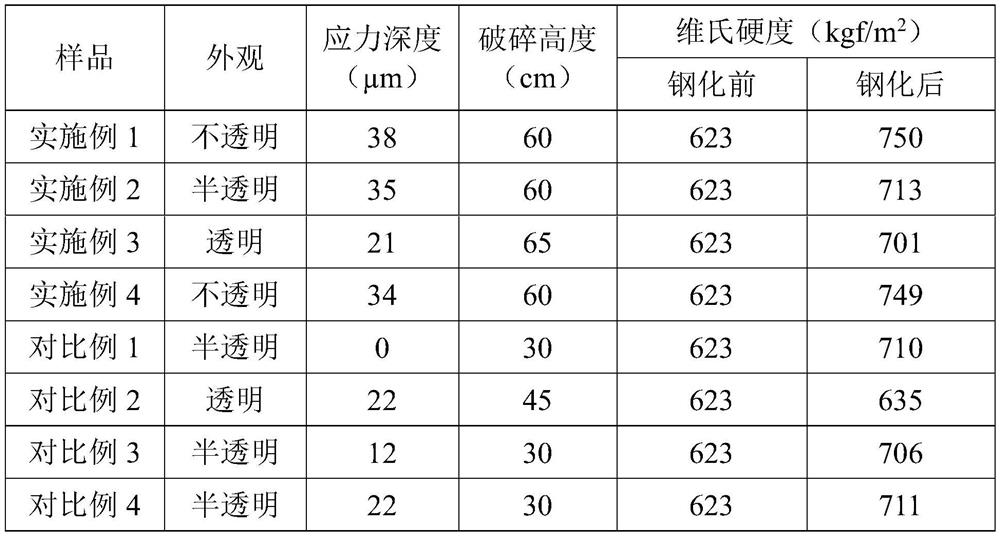

Examples

Embodiment 1

[0097] This embodiment provides a method for tempering glass-ceramic and a glass-ceramic prepared by the tempering method.

[0098] (1) The composition of the glass-ceramic precursor in this embodiment is as follows:

[0099] MgO 6%; ZnO 7%; Al 2 O 3 20%; SiO 2 50%; Na 2 O 4%; CaO 1%; SnO 2 1%; TiO 2 2%; ZrO 4%; P 2 O 5 2%; Sb 2 O 3 1%; B 2 O 3 2%.

[0100] The glass raw materials are: magnesium carbonate, zinc oxide, aluminum oxide, silicon dioxide, sodium carbonate, calcium carbonate, tin oxide, titanium dioxide, zirconium oxide, ammonium dihydrogen phosphate, sodium antimonate and boric acid.

[0101] After converting the ingredients, mix the glass raw materials and additives evenly, and put them into a glass melting furnace for melting at a temperature of 1550°C for 3 hours. After the melting is completed, it is poured into a mold preheated to 500° C. to form a large-volume glass-ceramic precursor.

[0102] (2) The glass-ceramic precursor is cut and pol...

Embodiment 2

[0109] This embodiment provides a method for tempering glass-ceramic and a glass-ceramic prepared by the tempering method.

[0110] (1) The composition of the glass-ceramic precursor in this embodiment is as follows:

[0111] MgO 6%; ZnO 7%; Al 2 O 3 20%; SiO 2 50%; Na 2 O 4%; CaO 1%; SnO 2 1%; TiO 2 2%; ZrO 4%; P 2 O 5 2%; Sb 2 O 3 1%; B 2 O 3 2%.

[0112] The glass raw materials are: magnesium carbonate, zinc oxide, aluminum oxide, silicon dioxide, sodium carbonate, calcium carbonate, tin oxide, titanium dioxide, zirconium oxide, ammonium dihydrogen phosphate, sodium antimonate and boric acid.

[0113] After converting the ingredients, mix the glass raw materials and additives evenly, and put them into a glass melting furnace for melting at a temperature of 1550°C for 3 hours. After the melting is completed, it is poured into a mold preheated to 500° C. to form a large-volume glass-ceramic precursor.

[0114] (2) The glass-ceramic precursor is cut and pol...

Embodiment 3

[0120] This embodiment provides a method for tempering glass-ceramic and a glass-ceramic prepared by the tempering method.

[0121] (1) The composition of the glass-ceramic precursor in this embodiment is as follows:

[0122] MgO 6%; ZnO 7%; Al 2 O 3 20%; SiO 2 50%; Na 2 O 4%; CaO 1%; SnO 2 1%; TiO 2 2%; ZrO 4%; P 2 O 5 2%; Sb 2 O 3 1%; B 2 O 3 2%.

[0123] The glass raw materials are: magnesium carbonate, zinc oxide, aluminum oxide, silicon dioxide, sodium carbonate, calcium carbonate, tin oxide, titanium dioxide, zirconium oxide, ammonium dihydrogen phosphate, sodium antimonate and boric acid.

[0124] After converting the ingredients, mix the glass raw materials and additives evenly, and put them into a glass melting furnace for melting at a temperature of 1550°C for 3 hours. After the melting is completed, it is poured into a mold preheated to 500° C. to form a large-volume glass-ceramic precursor.

[0125] (2) The glass-ceramic precursor is cut and pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com