Decolorization method of tylosin tartrate

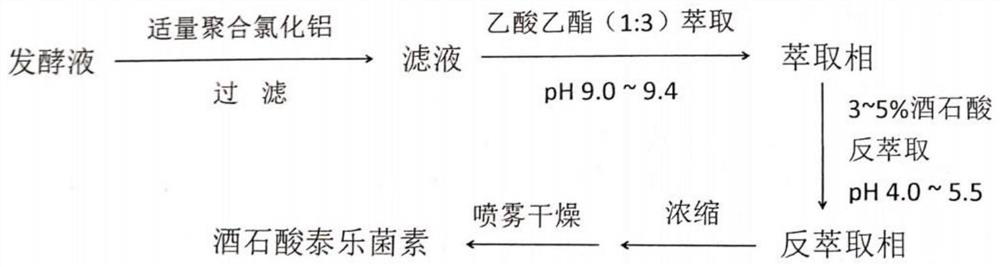

A technology of tylosin tartrate and secondary decolorization, which is applied in the field of decolorization of tylosin tartrate, can solve the problems of affecting the yield and purification effect of tylosin, difficult control of the operation process, and incomplete decolorization effect, etc. Achieve good decolorization effect, increase yield and purification effect, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Tylosin tartrate is decolorized with 3‰ activated carbon-3‰ silica gel-ultrafiltration membrane

[0026] Take 150g of tylosin tartrate powder (potency 6250μg / ml), add 2400ml of purified water and stir to dissolve. The clarity of the dissolved sample solution is Y3 (as a control group), and then add 3‰ of tylosin tartrate solution The activated carbon was stirred and allowed to stand for 30 minutes, the pH value of the solution was controlled to 4.5, and the temperature was 65°C, and then diatomaceous earth with a quality of 3‰ of tylosin tartrate solution was added for filter aid, and the activated carbon decolorization solution was obtained by filtration; to the activated carbon decolorization solution Add silica gel with a quality of 3‰ of tylosin tartrate solution to the mixture, stir, let it stand for 30min, then add diatomaceous earth with a quality of 3‰ of tylosin tartrate solution for filter aid, and filter to obtain silica gel decolorization solution;...

Embodiment 2

[0027] Embodiment 2: Tylosin tartrate is decolorized with 2‰ activated carbon-2‰ silica gel-ultrafiltration membrane

[0028] Take 150g of tylosin tartrate powder (potency 6250μg / ml), add 2400ml of purified water and stir to dissolve. The clarity of the dissolved sample solution is Y3 (as a control group), and then add tylosin tartrate solution with a quality of 2‰ The activated carbon was stirred and allowed to stand for 30 minutes, the pH value of the solution was controlled to 4.5, and the temperature was 65°C, and then diatomaceous earth with a quality of 2‰ of tylosin tartrate solution was added to filter, and the activated carbon decolorization solution was obtained by filtration; to the activated carbon decolorization solution Add 2‰ silica gel with the quality of tylosin tartrate solution to the mixture, stir, let it stand for 30min, then add 2‰ diatomaceous earth with the quality of tylosin tartrate solution for filter aid, and filter to obtain the silica gel decoloriz...

Embodiment 3

[0029] Example 3: Decolorization of tylosin tartrate with 4‰ activated carbon-4‰ silica gel-ultrafiltration membrane

[0030] Take 150g of tylosin tartrate powder (potency 6250μg / ml), add 2400ml of purified water and stir to dissolve. The clarity of the dissolved sample solution is Y3 (as a control group), and then add 4‰ of tylosin tartrate solution The activated carbon was stirred and allowed to stand for 30 minutes, the pH value of the solution was controlled to 4.5, and the temperature was 65°C, and then diatomaceous earth with a quality of 4‰ of tylosin tartrate solution was added to filter, and the activated carbon decolorization solution was obtained by filtration; to the activated carbon decolorization solution Add 4‰ of tylosin tartrate solution to silica gel and stir for 30 minutes, then add diatomaceous earth with 4‰ of tylosin tartrate solution to aid in filtration, and filter to obtain silica gel decolorization solution; finally, decolorize silica gel The liquid w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com