Polythiourea binder, preparation and application thereof, polymer bonded explosive based on polythiourea reinforcement and preparation method of polymer bonded explosive

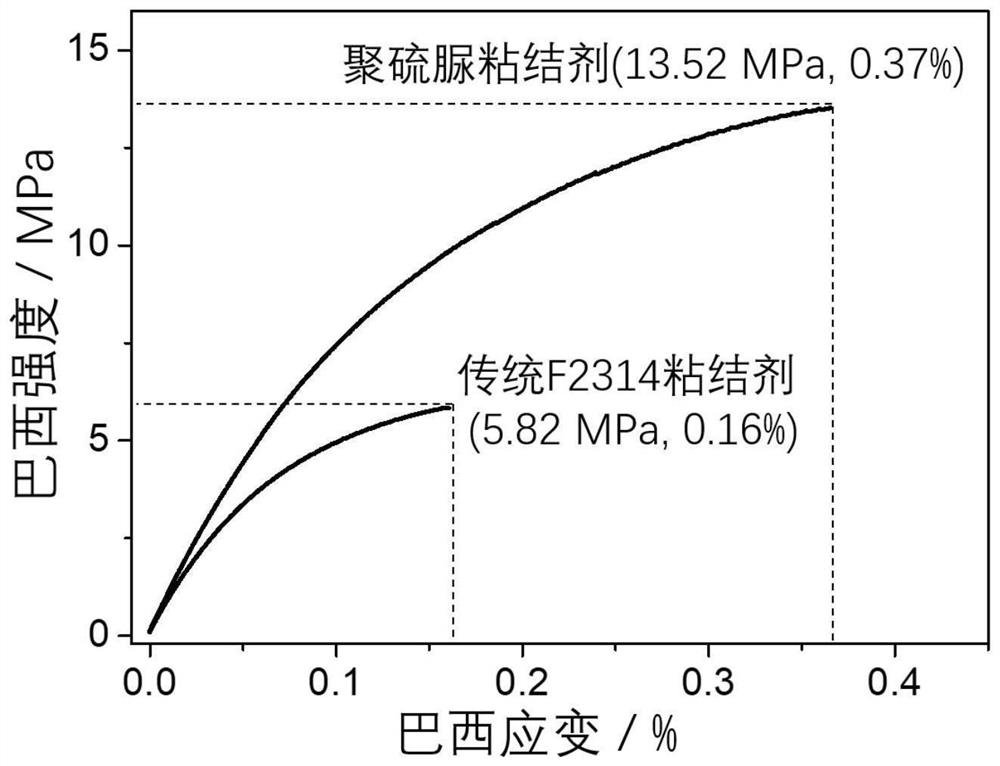

A technology for bonding explosives and polythiourea, which is applied in the directions of explosives, non-explosive/non-thermal agent components, non-explosive fillers/gelling agents/thickeners, etc. The mechanical properties of the material are low, and the mechanical properties need to be further optimized to achieve the effects of easy amplification, excellent performance, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

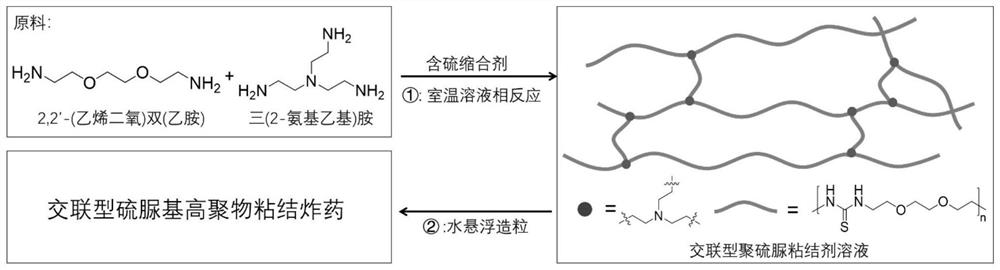

[0027] Example 1 prepares the schematic flow sheet of the high polymer bonding explosive based on polythiourea reinforcement as figure 1 shown.

Embodiment 1

[0029] Step 1: Preparation of polythiourea binder: 2,2'-(ethylenedioxy)bis(ethylamine) (6.8g) and tris(2-aminoethyl)amine (0.2g) (both collectively referred to as Amino monomer) was dissolved in 50mL N,N-dimethylformamide (DMF) to form a solution of 0.14g / mL, cooled to 0°C, and then N,N'-thiocarbonyldiimidazole ( 7g), at this time, the mass ratio of N,N'-thiocarbonyldiimidazole to amino monomers is (1:1). The system was slowly heated to 30° C. and reacted at a stirring rate of 1000 rpm for 48 hours. After the reaction is completed, add 100 mL of chloroform to the above solution and mix well, then pour it into 1.5 L of ether and let it stand for precipitation. Polythiourea binder solution, the obtained polythiourea molecular weight is 21.5kg / mol.

[0030] Step 2: Preparation of polymer bonded explosive based on polythiourea reinforcement: 1,3,5-triamino-2,4,6-trinitrobenzene (TATB) with an average particle size of 100 μm was added to deionized In water, carry out mechanical st...

Embodiment 2

[0033] Step 1: Preparation of polythiourea binder: 2,2'-(ethylenedioxy)bis(ethylamine) (9.5g) and tris(2-aminoethyl)amine (0.5g) (both collectively referred to as amino monomer) was dissolved in 50mL dimethyl sulfoxide (DMSO) to form a solution of 0.2g / mL and cooled to 25°C, then N,N'-thiocarbonyldiimidazole (5g) was added in small batches, at this time The mass ratio of N,N'-thiocarbonyldiimidazole to amino monomers is (1:2). The system was slowly heated to 30° C. and reacted at a stirring rate of 1000 rpm for 48 hours. After the reaction is completed, add 50 mL of chloroform to the above solution and mix thoroughly, then pour into 0.5 L of ether and let it stand for precipitation. Polythiourea binder solution, the gained polythiourea molecular weight is 20.3kg / mol;

[0034] Step 2: Preparation of polymer bonded explosive based on polythiourea reinforcement: 1,3,5-triamino-2,4,6-trinitrobenzene (TATB) with an average particle size of 100 μm was added to deionized In water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com