Smelting process for controlling aluminum increase at tail end of electroslag ingot in electroslag remelting process

A technology of electroslag remelting and electroslag ingot, which is applied in the field of electroslag metallurgy and can solve the problems of increasing aluminum at the end of electroslag ingot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

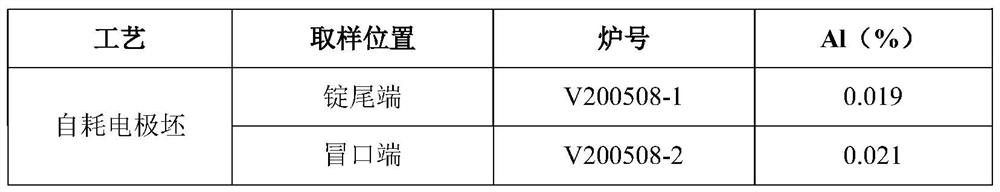

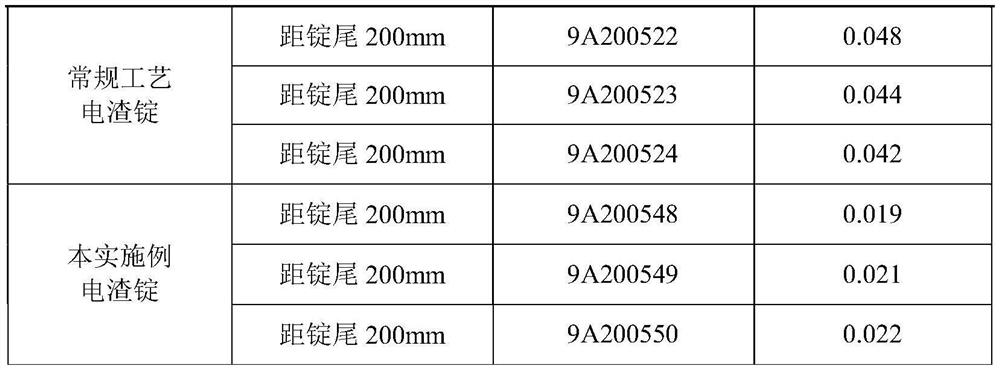

[0031] Example 1: A smelting process for controlling the addition of aluminum at the end of an electroslag ingot during the electroslag remelting process, remelting 6.8 tons of steel 30CrMnSiNi2MoVE for special products, the technical agreement requires Al≤0.025%, and the ingot type specification: Φ725 / Φ790mm; slag Department: CaF 2 :Al 2 o 3 : CaO=60:20:20; slag amount: 260kg, its specific operation method is as follows:

[0032] Step 1), the slag is pre-baked before remelting, wherein the fluorite powder is baked at not less than 600°C for ≥4 hours, kept at ≥200°C, and taken as needed; alumina powder and lime are not Bake at less than 700°C for ≥4 hours, keep warm at ≥200°C, and take it as you go;

[0033] Step 2) After the spindle guard is seated, place the arc ignition agent in the center of the spindle guard, and surround the arc ignition agent with fluorite powder to ensure that a slag pool is formed as soon as possible after arcing to prevent damage to the bottom cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com