Method for preparing anticorrosive coating on ocean wind power tower drum

A technology for wind power towers and coatings, which is applied in the fields of coating, wind energy power generation, and metal material coating processes, can solve the problems of complex preparation process, cumbersome process, and easy coating failure, achieve good process performance and reduce labor. , the effect of reducing process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

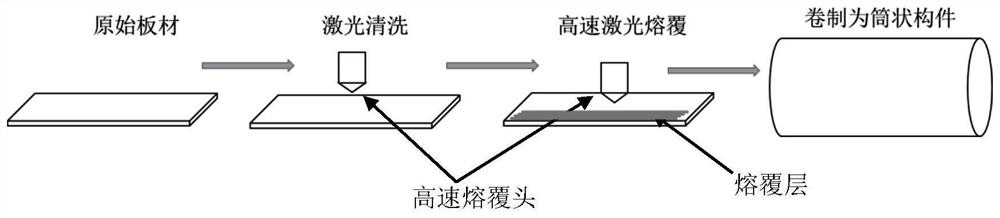

[0061] Such as figure 1 Shown: this embodiment provides a kind of method for preparing the anticorrosion coating of offshore wind power tower tube, and this method is:

[0062] (1) Nickel 60 (Ni60) powder is used according to actual needs, and the element content of the powder is shown in Table 1. The particle size range of the powder is 15-55μm, the powder sphericity is 97%, the proportion of the powder particle size segment is: 15-25μm accounts for 10%, 26-35μm accounts for 30%, 36-45μm accounts for 50%, 46-55μm Accounting for 10%. Dry it in a vacuum oven at 150°C and keep it warm for 3 hours.

[0063] (2) Place the grade Q345 plate substrate on the machine tool and fix it. The ultra-high-speed laser cladding head is above the plate and vertically downward. Adjust the ultra-high-speed laser cladding head to a suitable position.

[0064] (3) Use ultra-high-speed laser cladding equipment to use appropriate technology to clean the surface of the plate under the condition of ...

Embodiment 2

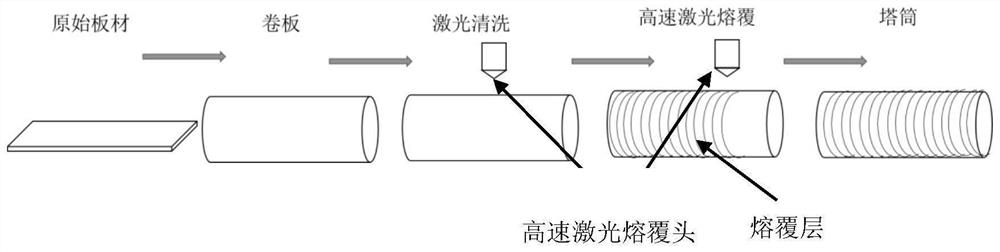

[0079] Such as figure 2 As shown: this embodiment provides a method for preparing an anti-corrosion coating for an offshore wind power tower by ultra-high-speed laser cladding, which includes the following process steps: firstly, the plate is rolled and welded into a cylinder member, and the weld is smoothed, Then it is fixed on the machine tool stably, and the ultra-high-speed laser cladding equipment is used for laser cleaning when the powder is not being fed. After cleaning, the coaxial powder-feeding ultra-high-speed laser cladding method is used to clad the cobalt-based anti-corrosion coating on the surface of the cylinder. Then use mechanical fine polishing to make the size and surface roughness of the processed parts reach the specified value. Its specific process steps are:

[0080] (1) The powder element content of the cobalt-based powder (CoCrMo) is shown in Table (2). After optimized particle size ratio: 15-25μm accounted for 10%, 26-35μm accounted for 25%, 36-45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com