Ammonium metavanadate dewatering system and ammonia-rich dewatering method of ammonium metavanadate

An ammonium metavanadate and water tank technology is applied in the ammonium metavanadate dehydration system and in the field of ammonia-rich dehydration of ammonium metavanadate, which can solve problems such as low dehydration efficiency, reduce production, eliminate reprocessing procedures, and ensure dehydration quality. and dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

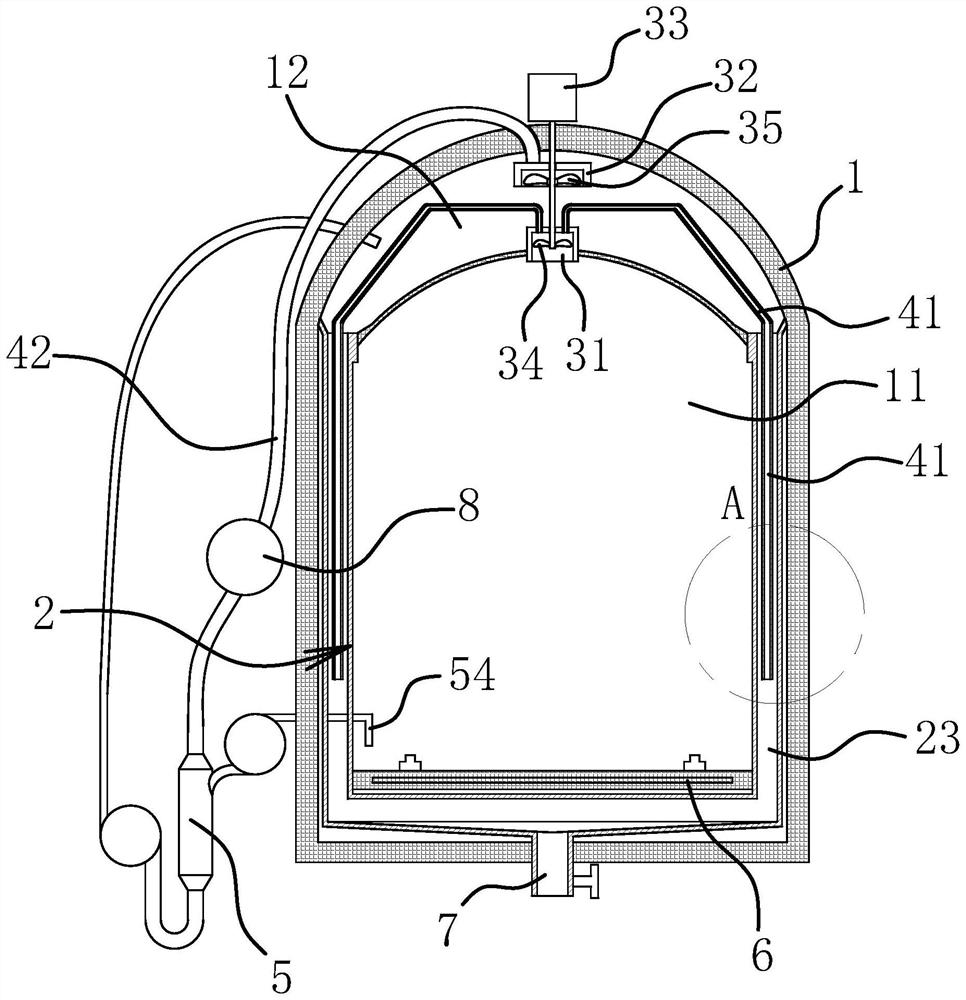

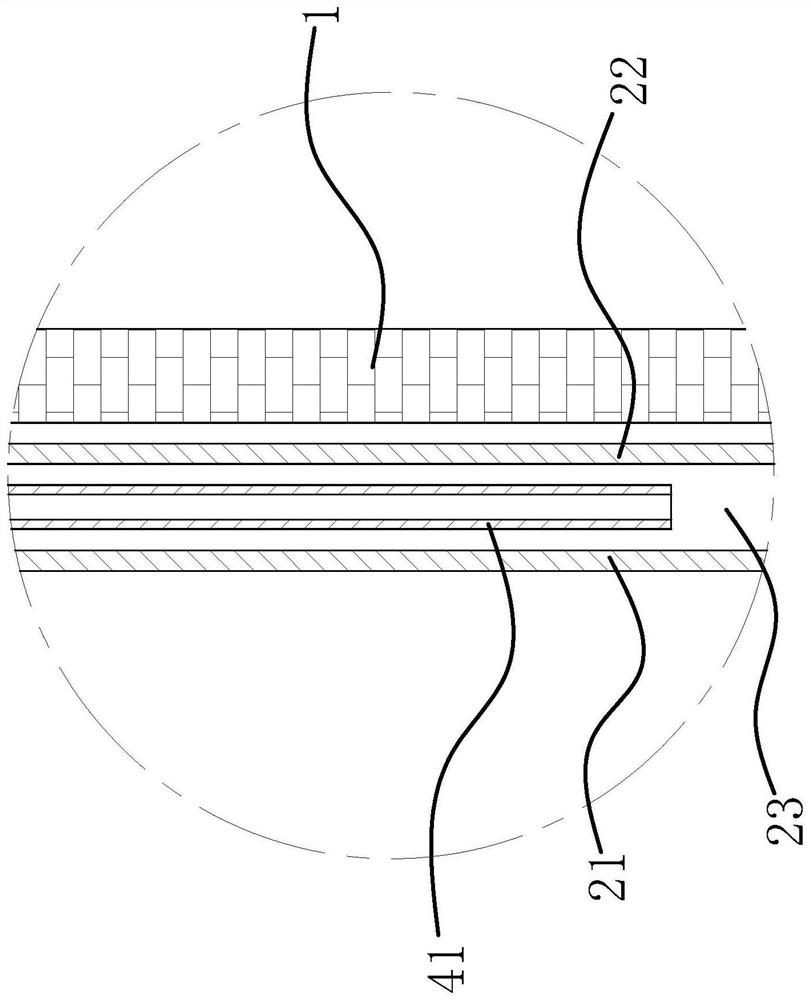

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0035] The dehydration method comprises the steps:

[0036] Cake or granulate industrial ammonium metavanadate;

[0037] Sealed heating is carried out in a dehydration furnace in an ammonia-rich environment, and the drying temperature is controlled between 120 and 160 °C;

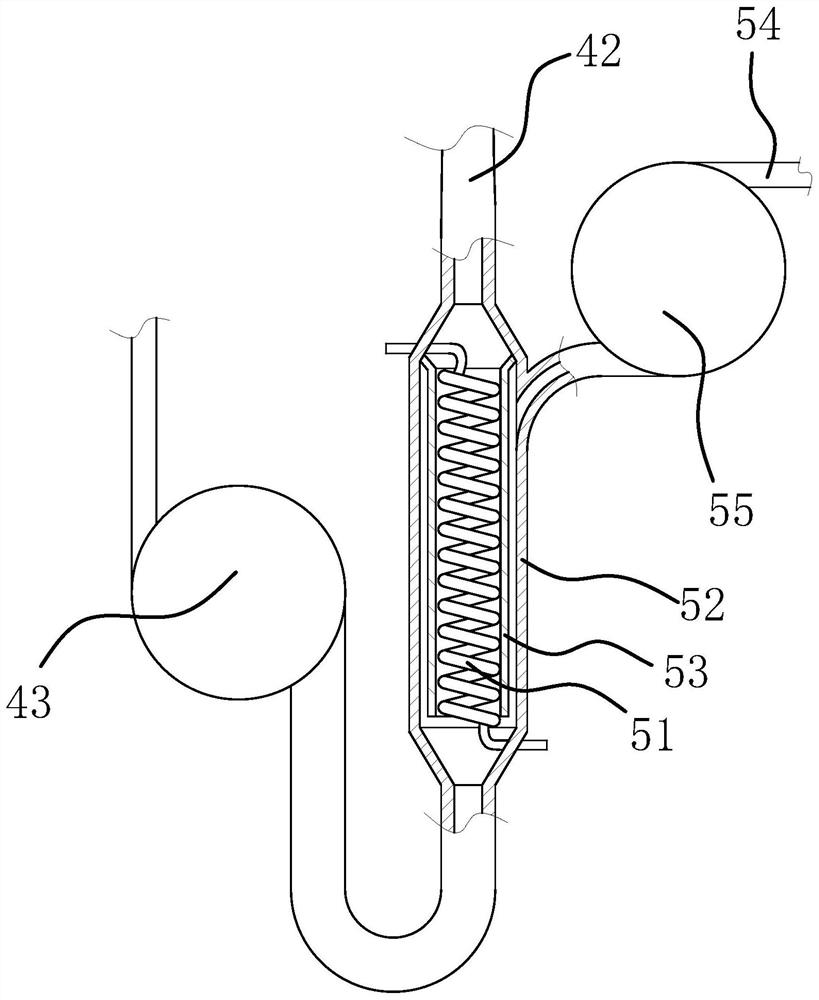

[0038] Collect the ammonia gas and water vapor generated in the dehydration furnace, separate the ammonia gas by condensation, and send the separated ammonia gas back to the dehydration furnace;

[0039] After the continuous dehydration meets the dehydration requirements, stop heating the dehydration furnace, and the ammonia gas does not stop flowing back, until the temperature in the dehydration furnace drops to between 50 and 80°C, the dehydration is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com