Oil-water separation method based on magnetic Janus particles

A kind of oil-water separation and magnetic technology, which is applied in the direction of separation method, immiscible liquid separation, liquid separation, etc., can solve the problems of oil-water separation technology research, oil-water separation effect is difficult to achieve the ideal effect, etc., to simplify industrial equipment and reduce industrial The effect of cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

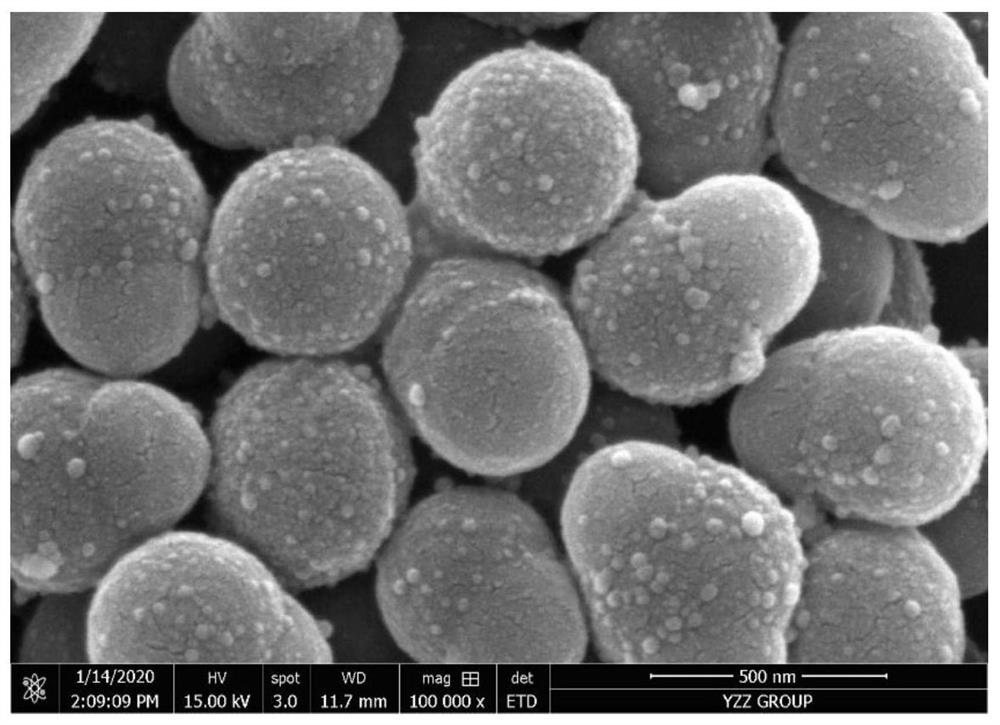

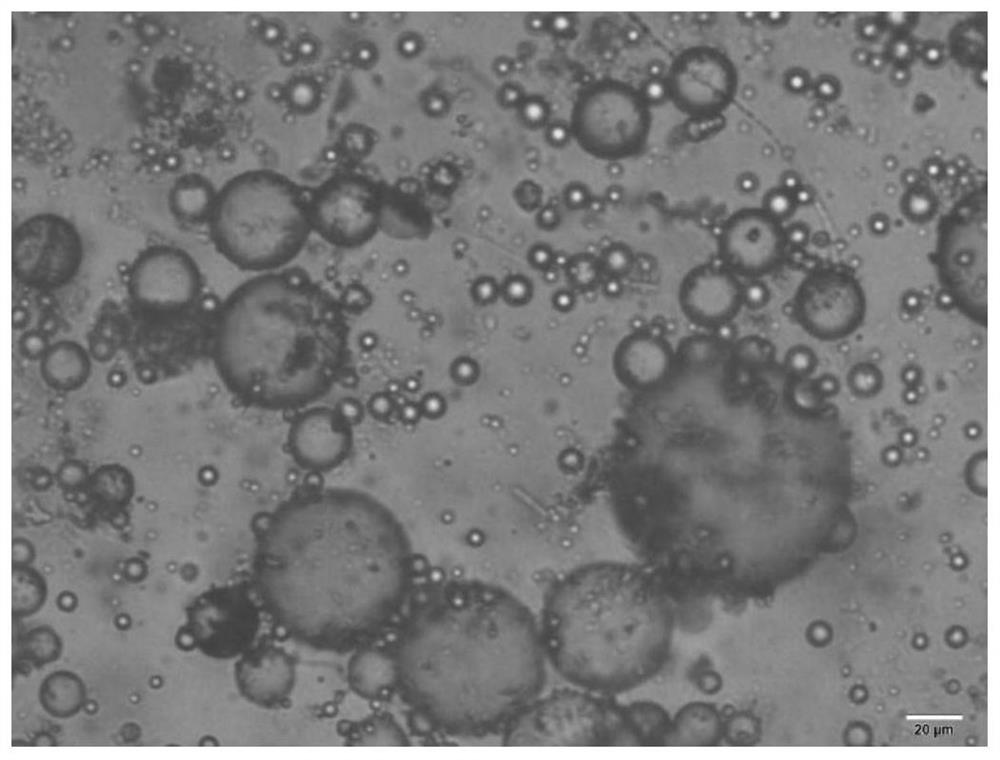

[0087] In a mixture of 20 ml of water and 2 ml of n-hexane, 0.1 g (0.45% by weight relative to the amount of the mixture) of magnetic Janus particles (such as figure 1 Magnetic silica / polystyrene-divinylbenzene Janus particles shown in ). Stir at a high speed of 1000r / min for 2min to form an oil-in-water emulsion. Adsorb the system with a 0.3T magnet for 5 minutes, and the n-hexane droplets (dispersed phase) stabilized by magnetic Janus particles are enriched and fixed by a magnetic field, so that the aqueous phase as the continuous phase flows out, thereby separating and containing n-hexane stabilized by magnetic Janus particles For the enriched emulsion part of the alkane droplets, the oil-water separation efficiency (oil-water separation efficiency=the weight of the separated oil phase (n-hexane in this embodiment) / the total weight of the oil phase in the mixture) is 90%.

[0088] To the obtained enriched emulsion part, an external magnetic field was applied with a 3T mag...

Embodiment 2

[0090] In 200ml refinery oily sewage, add 0.4g (relative to the amount of refinery oily sewage, 0.2% by weight) magnetic Janus particles (such as figure 1 Magnetic silica / polystyrene-divinylbenzene Janus particles shown in ), stirred at a high speed of 1000r / min for 2min to form an emulsion. After the system was adsorbed by a 0.8T magnet for 5 minutes, the water phase as the continuous phase flowed out, thereby separating the enriched emulsion part containing the oil stain stabilized by the magnetic Janus particles, realizing oil-water separation, and the oil-water separation efficiency was 92%.

[0091] To the obtained enriched emulsion part, an external magnetic field was applied with a 3T magnet, thereby demulsifying the enriched emulsion part. Magnetic Janus particles were recovered by continuously applying an external magnetic field with a 3 T magnet. Further, 100 ml of dichloromethane was added to the magnetic Janus particles, washed twice, and vacuum-dried to obtain m...

Embodiment 3

[0093] In 10ml of kitchen sewage, add 0.1g (relative to the amount of kitchen sewage, 1% by weight) magnetic Janus particles (such as figure 1 Magnetic silica / polystyrene-divinylbenzene Janus particles shown in ), stirred at a high speed of 2000r / min for 1min to form an emulsion. A 0.3T magnet was used to adsorb the system for 5 minutes, so that the water phase as the continuous phase flowed out, thereby separating the enriched emulsion part containing the oil stain stabilized by the magnetic Janus particles, realizing oil-water separation, and the oil-water separation efficiency was 95%.

[0094] To the obtained enriched emulsion part, an external magnetic field was applied with a 3T magnet, thereby demulsifying the enriched emulsion part. Magnetic Janus particles were recovered by continuously applying an external magnetic field with a 3 T magnet. Further, 20 ml of dichloromethane was added to the magnetic Janus particles, washed twice, and vacuum-dried to obtain magnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com